Efficient thermal forming food storage box production line

A thermoforming and storage box technology, applied in the field of high-efficiency thermoforming food storage box production lines, can solve the problems of insufficient heating and softening, uneven thickness of the box body or box cover, and easy damage to the box body or box cover, and achieves consistent softening strength. , softening effect, overall balanced and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be further described in conjunction with the accompanying drawings and specific embodiments, wherein the plastic roll conveying device, thermoforming mold, suction cup of the blow molding device, finished product conveying device, and edge material collecting device are all existing mechanisms, and the Chinese patent document: CN201320226306.X A thermoforming mold with an inverted container, CN201820573331.8 a blow molding device for cup lid thermoforming equipment, CN201610728287.9 a self-shearing mold of a thermoforming mechanism with a vacuum negative pressure structure, etc. have all been disclosed and are implemented as follows The example does not describe in detail.

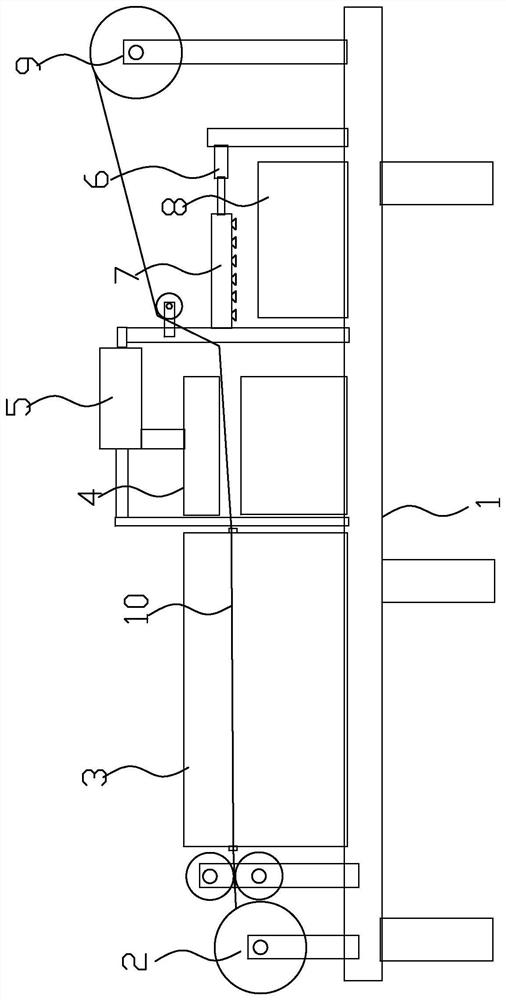

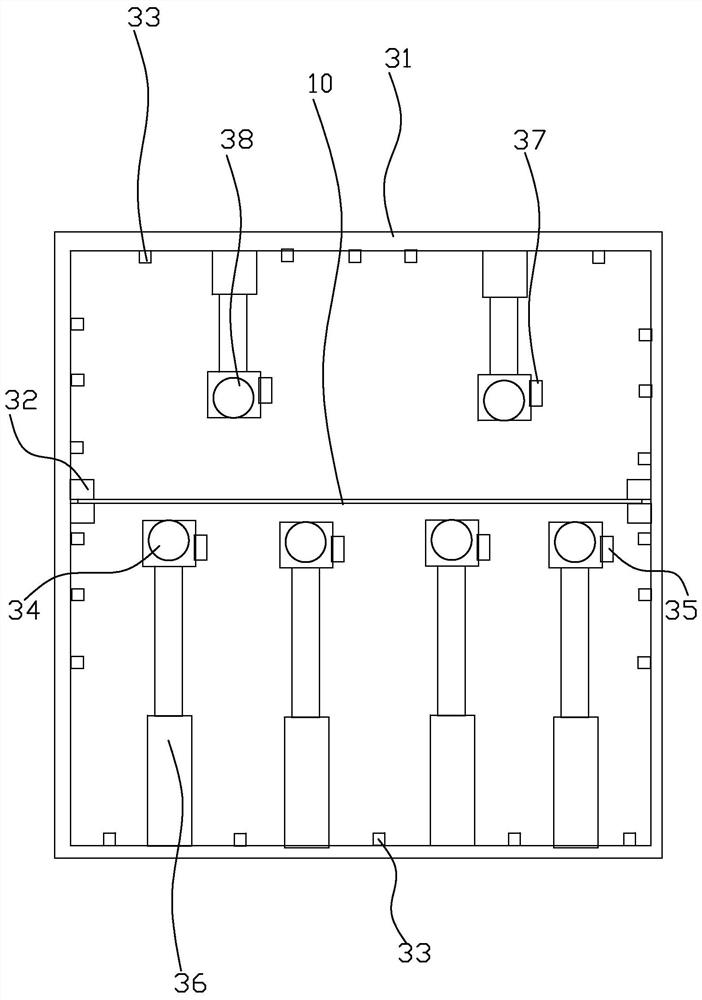

[0015] refer to figure 1 and figure 2 , the preferred high-efficiency thermoformed food storage box production line of the present invention includes a control system, a plastic roll conveying device 2 arranged on a frame 1, a plastic film heating and softening dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com