Battery pole piece multi-stage softening machine

A battery pole piece and softening machine technology, which is applied in the direction of alkaline battery electrodes, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of failure to fully synchronize softening, crease surface powder, shedding, etc., and achieve internal and external Consistent softening effect, uniform softening force and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

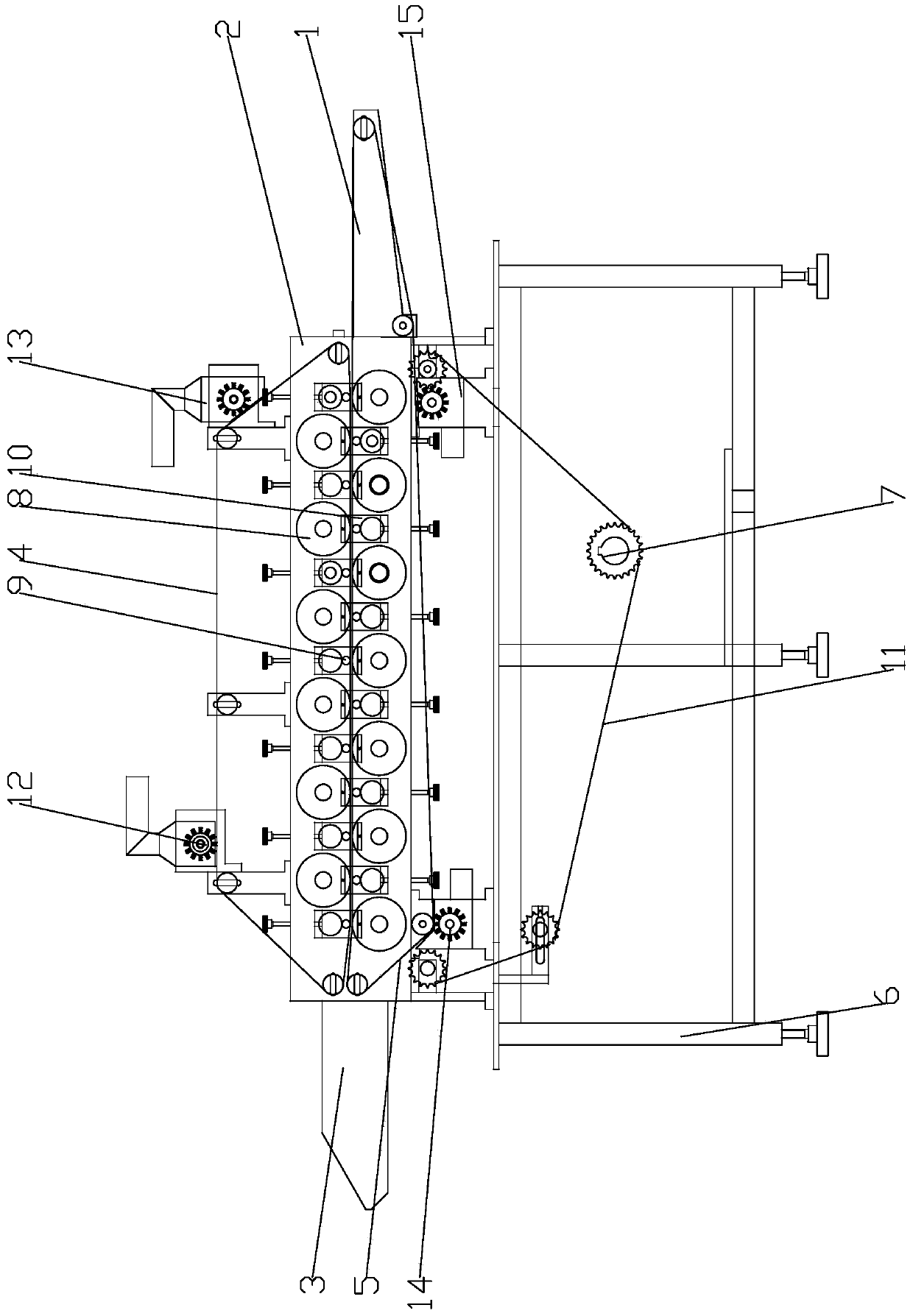

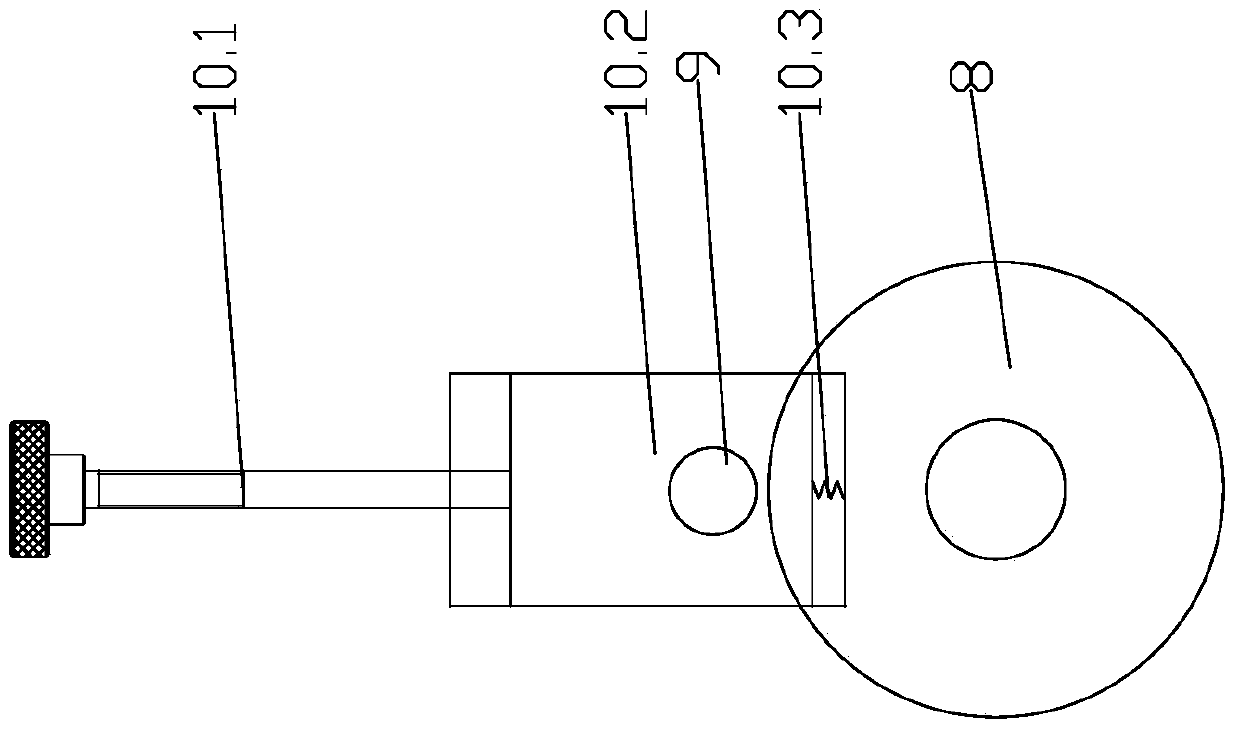

[0019] Such as figure 1 Shown, the present invention mainly comprises main frame 2, and main frame 2 top is provided with upper conveyor belt 4, and main frame 2 bottom is provided with lower conveyor belt 5. The upper and lower parts of the main frame 2 are provided with two rows of rubber rollers 8 up and down, and the two rows of rubber rollers 8 are staggered up and down. A metal pressure roller 9 is correspondingly provided at the front end of each rubber roller 8 .

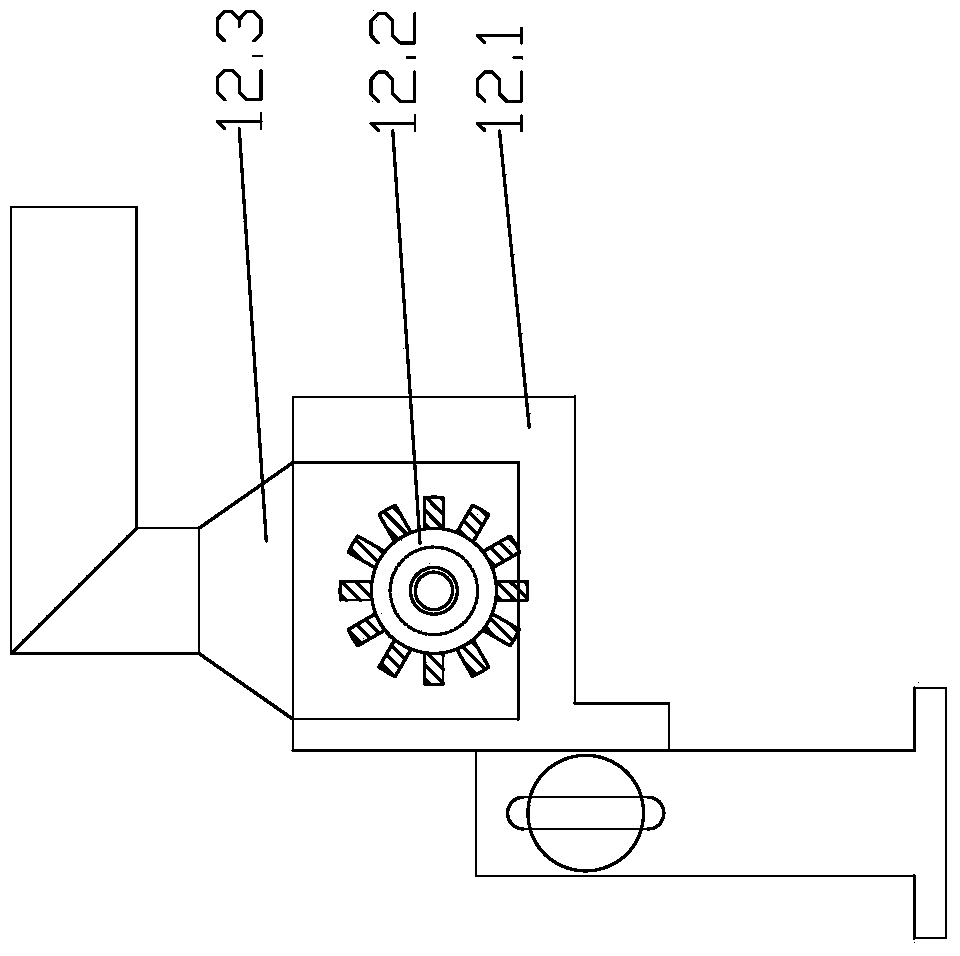

[0020] The lower part of the main frame 2 is provided with a reduction motor 7, the output end of the reduction motor 7 is connected to a transmission chain 11, and the transmission chain passes through a plurality of rubber rollers 8 in turn, and the reduction motor 7 drives a plurality of rubber rollers 8 to rotate synchronously through the transmission chain 11.

[0021] The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com