Superfine product film covering and plastic packaging equipment

A technology for covering film and products, which is applied in the directions of packaging/bundling items, transportation and packaging, packaging, etc., which can solve the problems of low efficiency of artificial covering film, waste of manpower, increase of production cost, etc., to meet the needs of large-scale production and save manpower , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

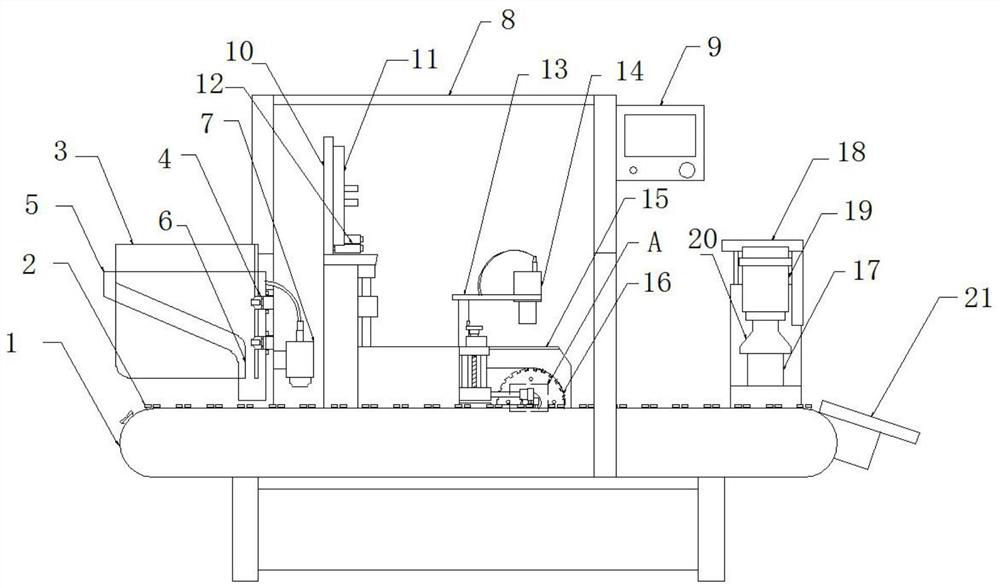

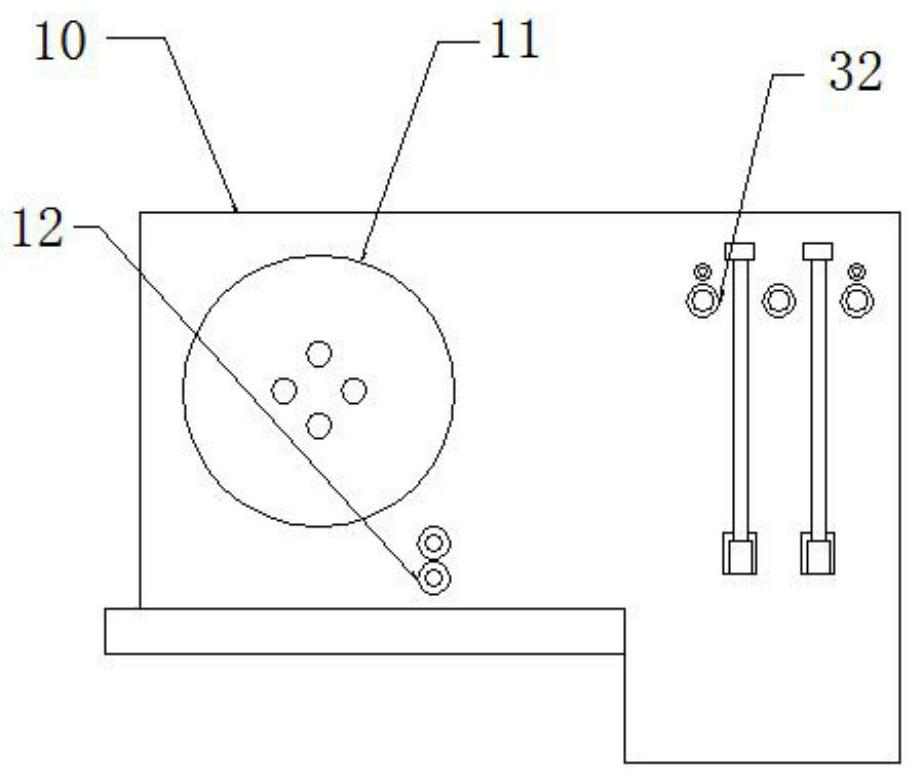

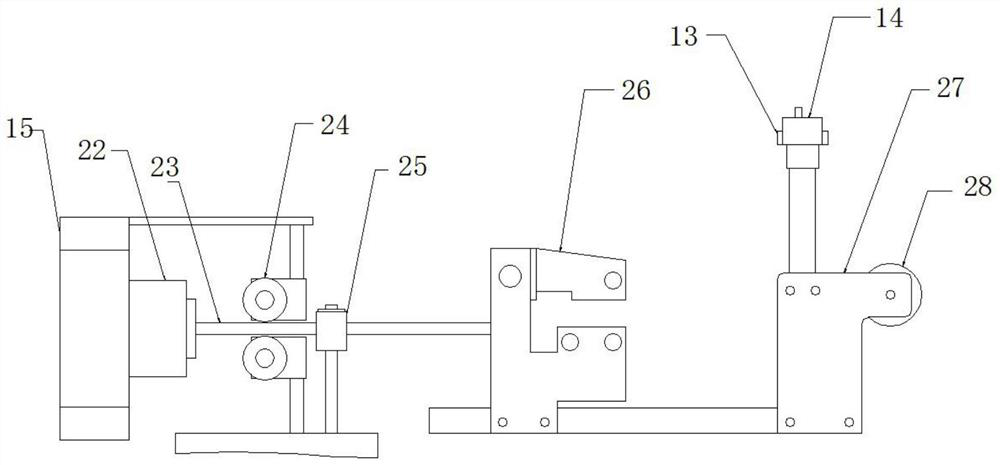

[0022] see Figure 1-4 , the present invention provides a technical solution: an ultra-fine product casing plastic sealing equipment, including a base, a material storage mechanism, a conveying mechanism 1, a film roll fixing plate 11, a traction mechanism, a steering mechanism, a coding device 14, and a casing mechanism With the heat shrink mechanism, the conveying mechanism 1 is installed on the base, and a support 8 is also installed on the base, and a control display 9 is installed on the support 8, and the control display 9 can display the working status of the equipment. The conveying mechanism 1 is installed with a limit mold 2, and the limit film is used to limit the uncoated product to prevent the product from shaking left and right. The right side of the conveying mechanism 1 is provided with a discharge port 21, and the storage mechanism is installed on the bracket 8 on the left side, and the discharge port 6 of the storage mechanism is located above the conveying m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com