Radish tassel removing device

A radish and sliding installation technology, which is applied in the field of radish destalling devices, can solve the problems of not being able to apply radish, not being able to adapt to radish, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

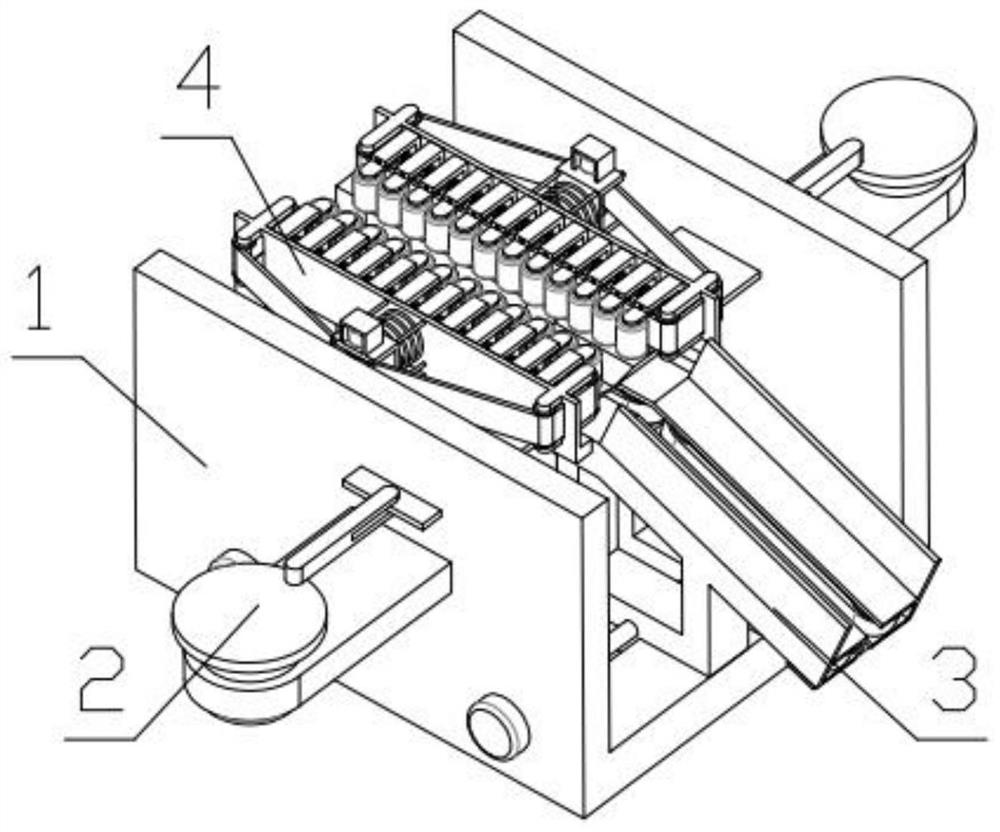

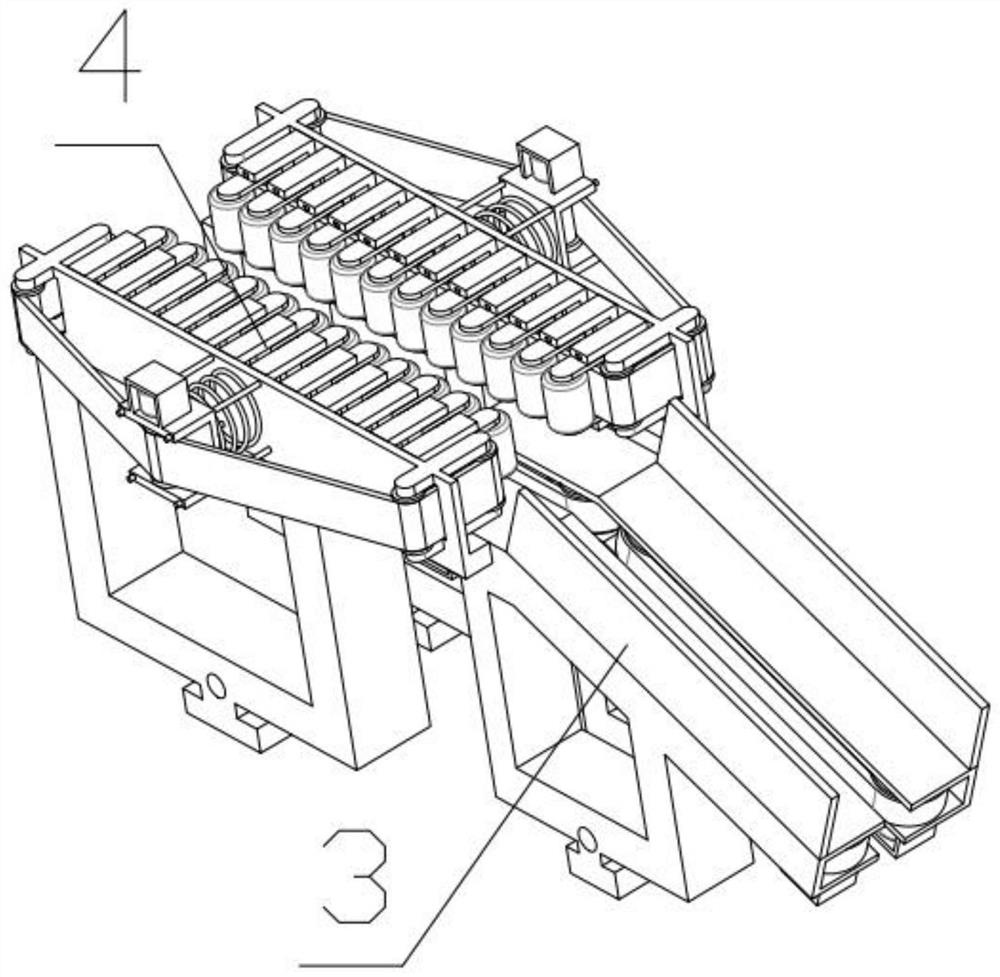

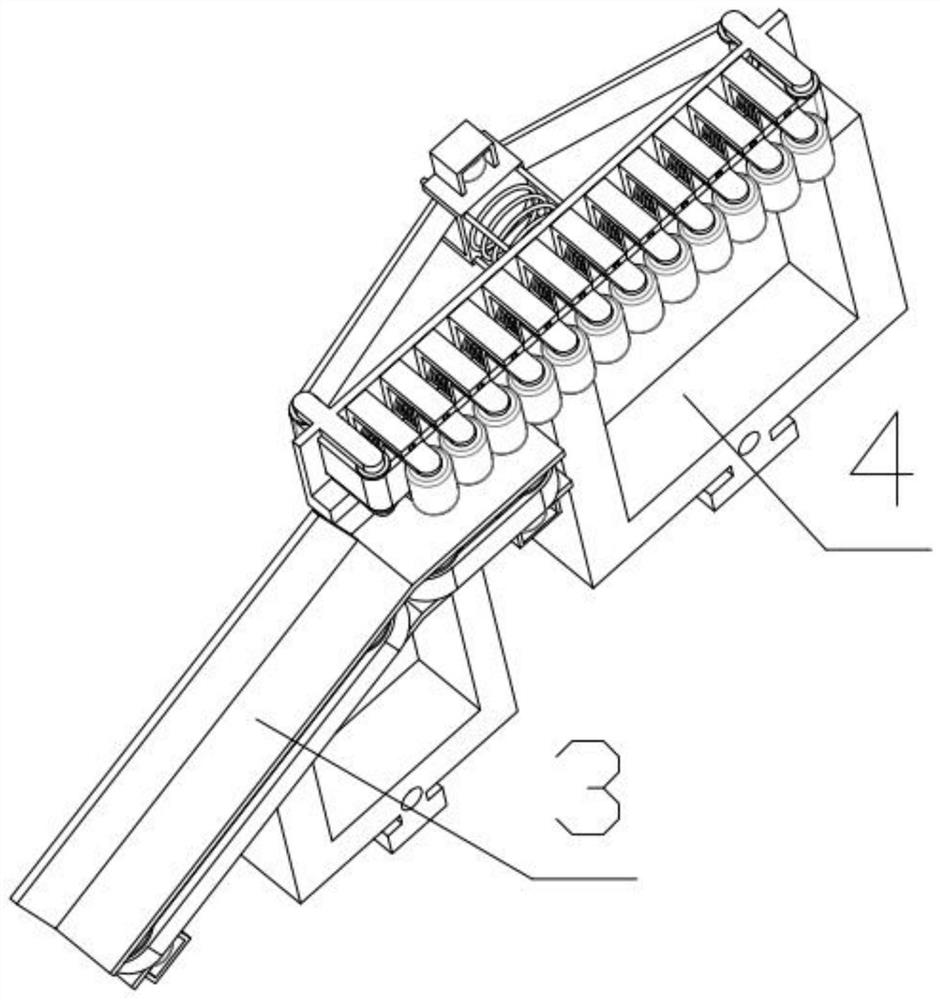

[0031] Combine below Figure 1-12 Description of this embodiment, a radish destalling device, including a spacing adjustment mechanism 1, a cutting mechanism 2, a flow diversion mechanism 3 and a conveying mechanism 4, the cutting mechanism 2 is fixedly installed on the spacing adjustment mechanism 1, the flow diversion mechanism 3 and the spacing The adjustment mechanism 1 is threaded, the diversion mechanism 3 is slidably installed in the groove provided on the spacing adjustment mechanism 1, the conveying mechanism 4 is threaded with the spacing adjustment mechanism 1, and the conveying mechanism 4 is slidably installed in the groove provided on the spacing adjustment mechanism 1 , the cutting mechanism 2 is slidably installed in the through hole provided on the conveying mechanism 4 .

specific Embodiment approach 2

[0033] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain the first embodiment, the distance adjustment mechanism 1 includes a main frame 1-1, a first motor 1-2, a second motor 1-3, a first two-way threaded rod 1- 4. The second two-way threaded rod 1-5, the first motor 1-2 is fixedly installed in the through hole provided on the main frame 1-1, and the second motor 1-3 is fixedly installed in the through hole provided on the main frame 1-1. In the hole, the output end of the first motor 1-2 is fixedly installed with the first two-way threaded rod 1-4, and the first two-way threaded rod 1-4 is rotatably installed in the groove provided on the main frame 1-1, and the second motor The output end of 1-3 is fixedly installed with the second two-way threaded rod 1-5, and the second two-way threaded rod 1-5 is rotatably installed in the groove provided on the main frame 1-1.

specific Embodiment approach 3

[0035] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the cutting mechanism 2 includes a motor mounting plate 2-1, a third motor 2-2, an eccentric wheel 2-3, a swing rod 2-4, a cutting Knife 2-5, the 3rd motor 2-2 are fixedly installed in the through hole that motor installation plate 2-1 is provided with, the output end of the 3rd motor 2-2 is fixedly installed with eccentric wheel 2-3, swing bar 2-4 One end of the swing rod is rotatably installed in the groove provided on the eccentric wheel 2-3, the other end of the swing rod 2-4 is hinged with the cutting knife 2-5, and the cutting knife 2-5 is slidably installed on the main frame 1-1. In the through hole, a motor mounting plate 2-1 is fixedly installed on the main frame 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com