Method for separating and purifying trigonelline, chlorogenic acid and caffeine

A trigonelline, separation and purification technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

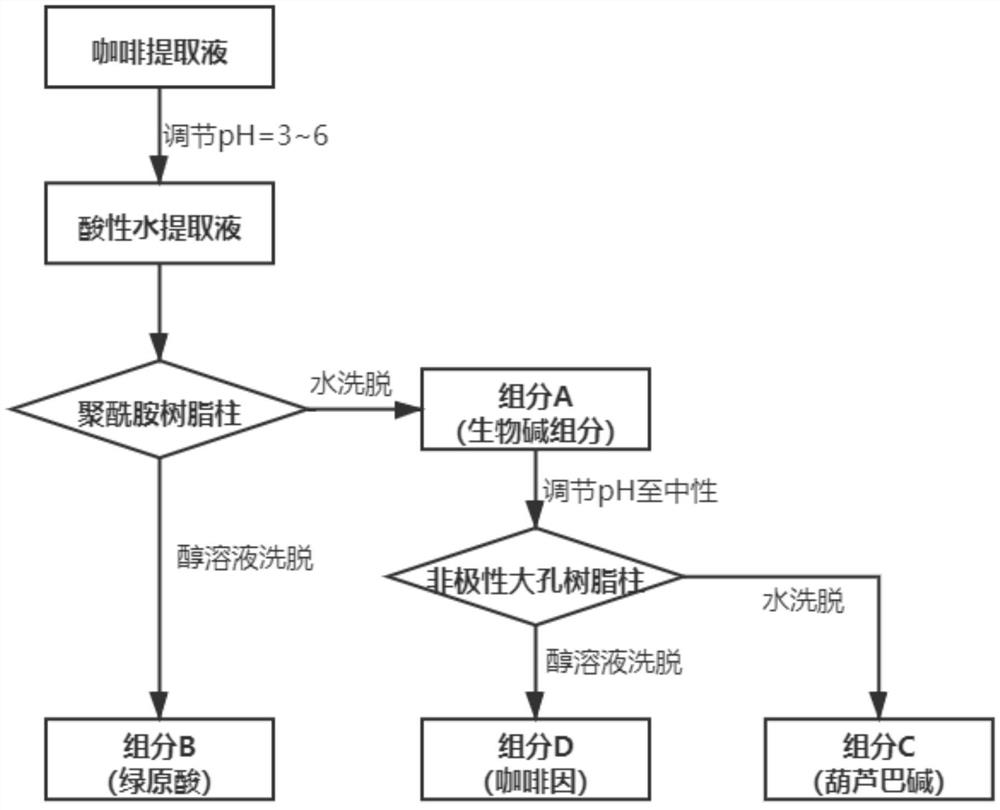

Method used

Image

Examples

Embodiment 1

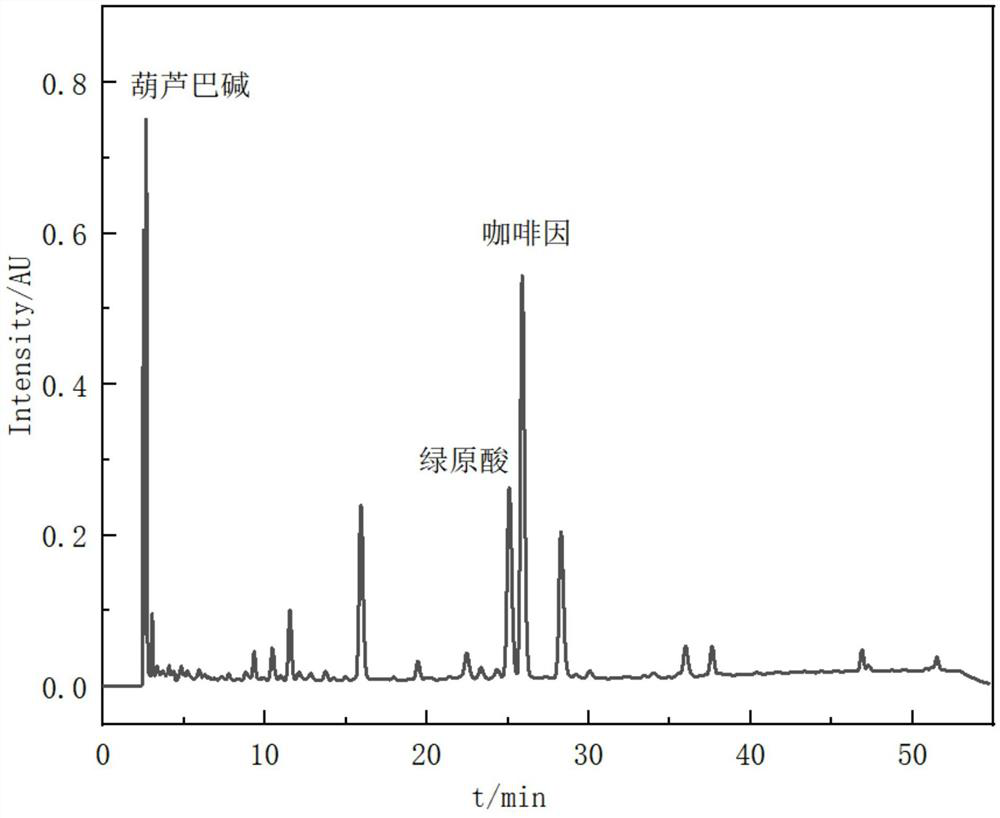

[0036] A. The coffee extract is properly concentrated, and the analysis results are as attached figure 2 As shown, adjust the pH of the extract to 3, and the acidic coffee extract is loaded onto the polyamide adsorption resin column with a flow rate of 4BV / h (BV, resin column bed volume);

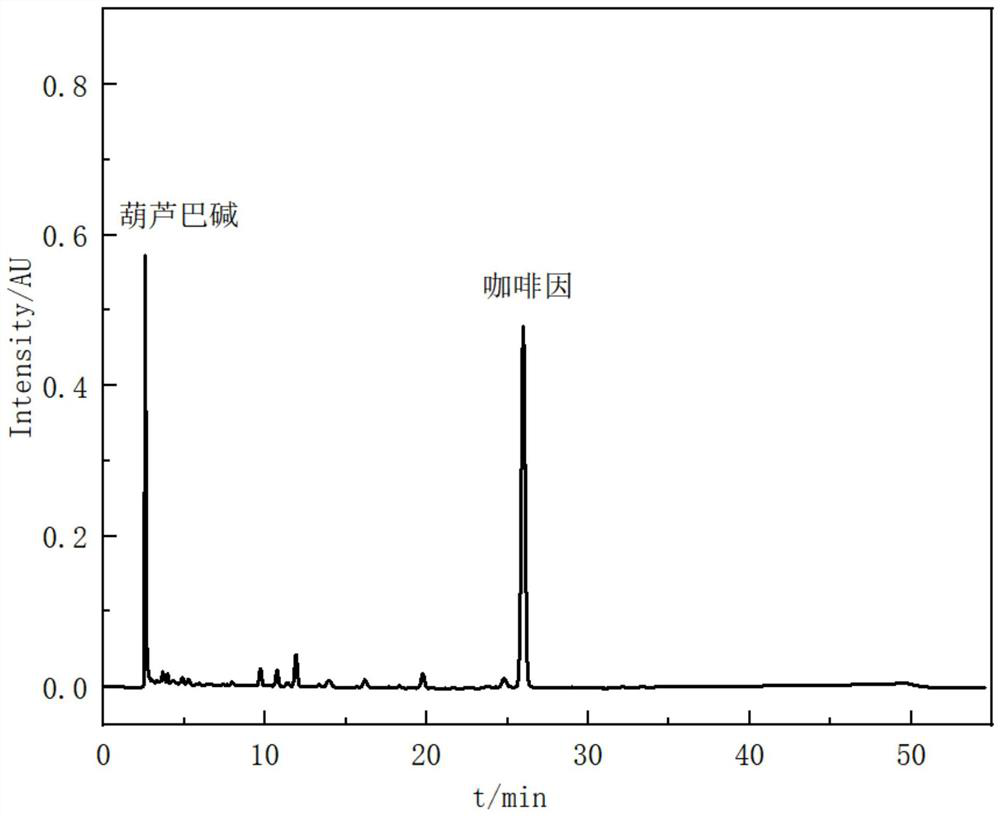

[0037] B. Use 5BV of water to elute first, and the analysis results of the eluate are as attached image 3 shown. Carry out elution with 50% ethanol of 5BV again, collect eluate respectively, eluate analysis result is as follows Figure 4 As shown, the chromatographic purity of the chlorogenic acid content in the alcohol eluent obtained was 30.13%.

Embodiment 2

[0039] A. The coffee extract is properly concentrated, adjusted to pH=6, and the acidic coffee extract is loaded onto the polyamide adsorption resin column at a flow rate of 4BV / h;

[0040] B. First eluted with 5BV of water, then eluted with 5BV of 50% ethanol, collected the eluents respectively, and obtained a chromatographic purity of chlorogenic acid content in the ethanol eluents of 31.44%.

Embodiment 3

[0042] A. The coffee extract is properly concentrated, adjusted to pH=4, and the acidic coffee extract is loaded onto the polyamide adsorption resin column at a flow rate of 4BV / h;

[0043] B. First use 5BV of water to elute, then use 5BV of 50% ethanol to elute, collect eluents respectively, and obtain the chromatographic purity of chlorogenic acid content in the ethanol eluent as 31.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com