Fabricated round steel tube bundle and corrugated plate combined wall column beam structure system

A round steel pipe and corrugated plate technology is applied in the field of assembled round steel pipe bundle corrugated plate combined wall-column-beam structure system, which can solve the problems of large amount of steel used in light steel keel structure, high consumption of resources and energy, and large environmental pollution, etc. Improve the bearing capacity of the structure, excellent seismic performance, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

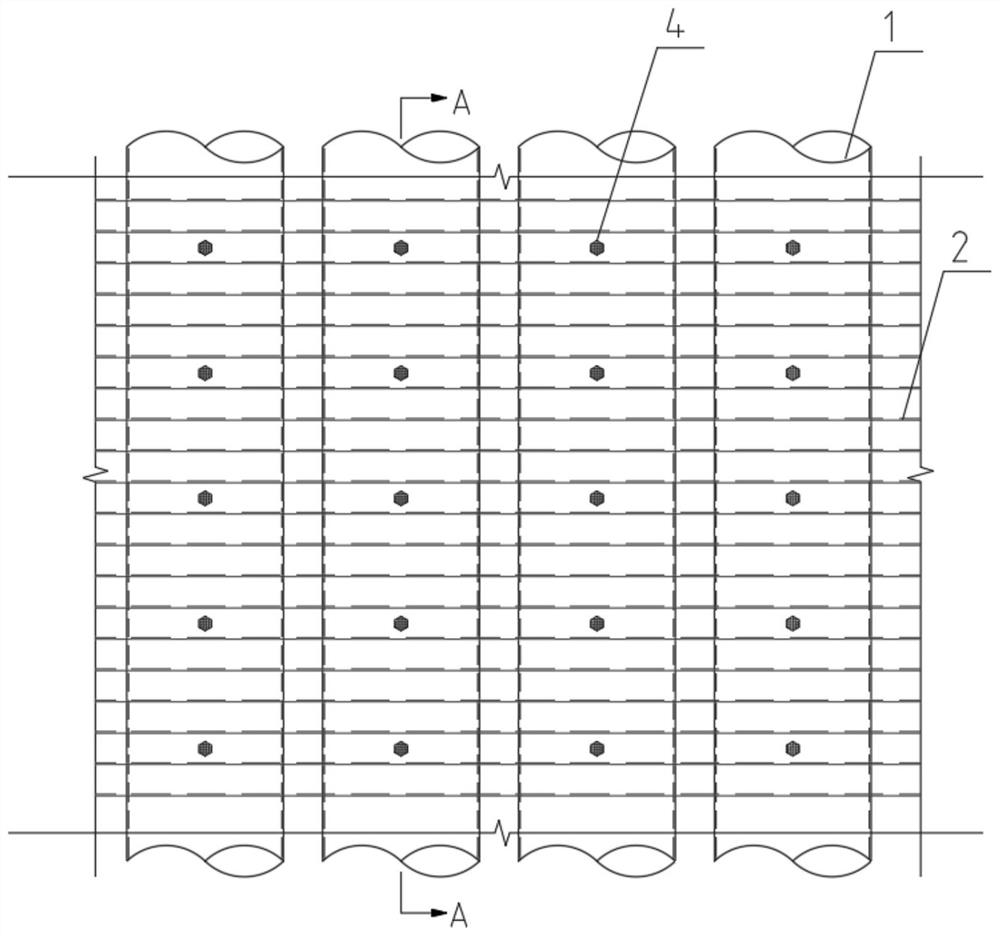

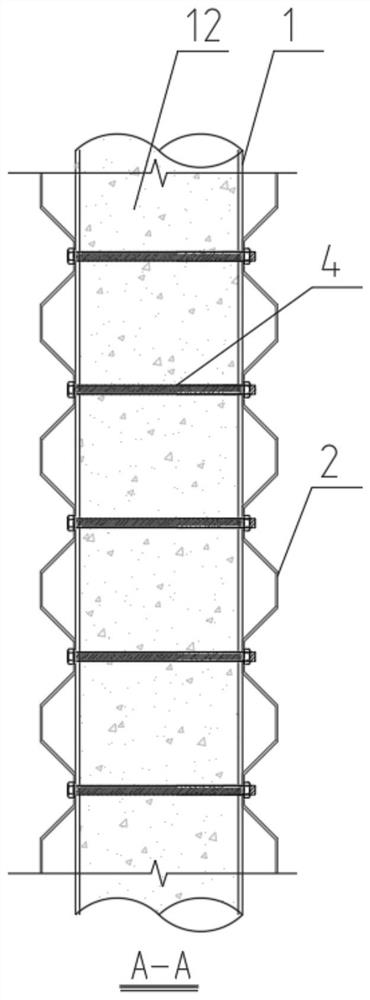

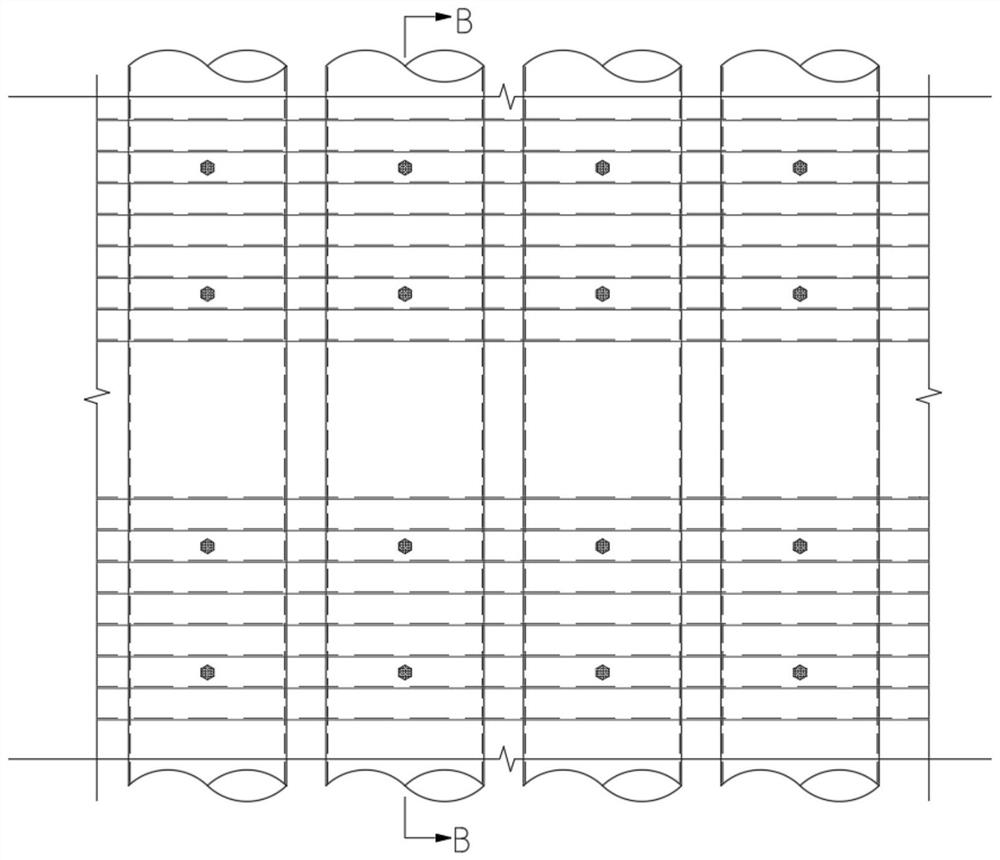

[0072] continue to see Figure 14-15 , as an embodiment of the present invention, on the basis of forming the core plate 7, the present invention further provides bolt holes (not marked in the figure) on the inner and outer sides of the connecting section of the round steel pipe 1, while the core plate 7 Bolt holes are also correspondingly provided, and a bolt 4 is adopted to pass through the core plate 7 from one side of the round steel pipe 1, and is fixed on the round steel pipe 1 by nuts on the other side of the pipe wall. After the bolt 4 passes through the round steel pipe 1, it is fixed on the round steel pipe 1 by nuts. After the inside of the round steel pipe 1 is poured with concrete, the bolt 4 forms an anchor in the round steel pipe 1. Since the bolt 4 passes through the core plate 7 vertically, the anchored bolt 4 Forming a tie effect on the core plate 7 can also greatly enhance the connection strength of the beam-column joints, preventing the core plate 7 from sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com