FRP-steel-block coal gangue concrete combined supporting structure and construction method

A technology of coal gangue concrete and support structure, which is applied in earth square drilling, solid waste management, sustainable waste treatment, etc. It can solve the problems of insufficient strength and achieve the effect of increasing strength and delaying buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

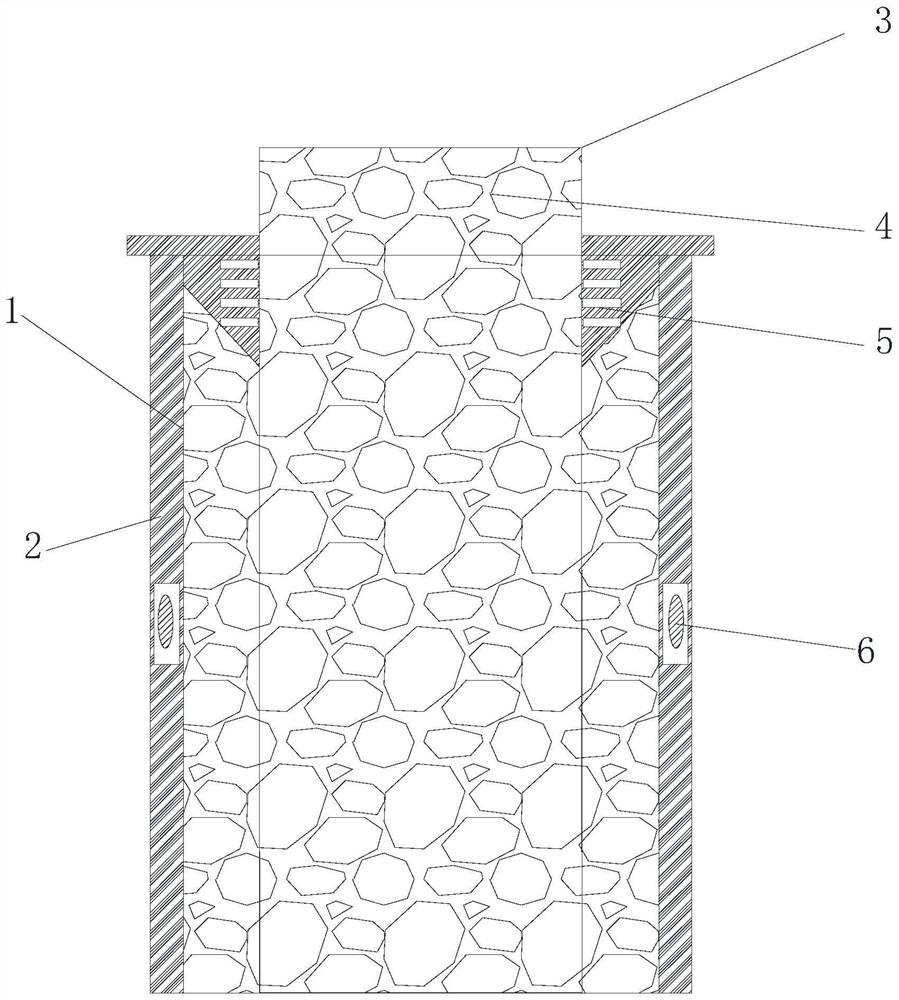

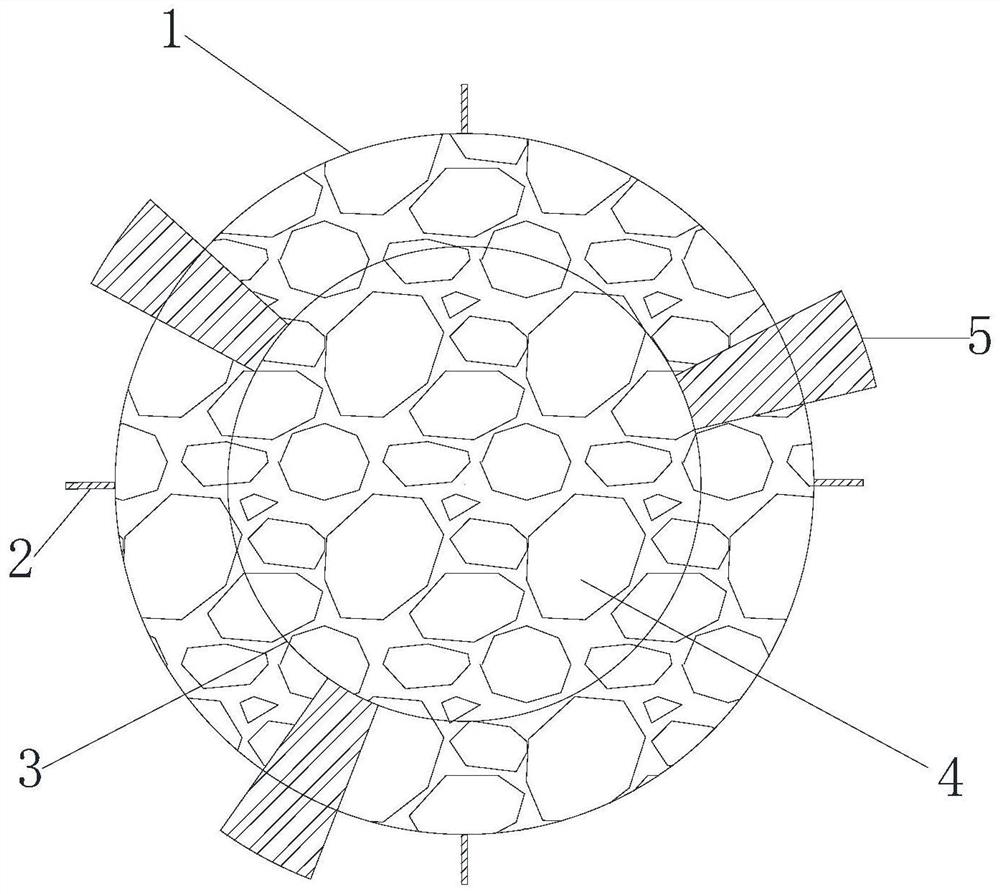

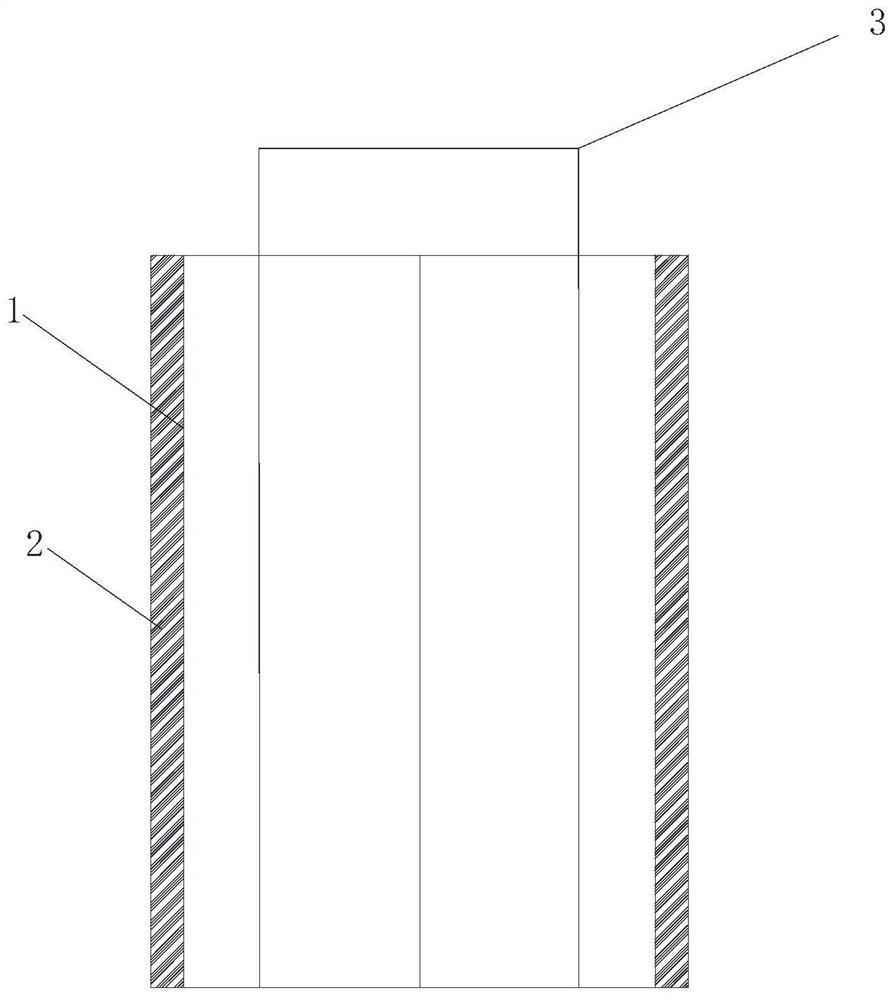

[0036] see attached Figure 1-5 As shown, a FRP-steel-block coal gangue concrete composite supporting structure of the present embodiment comprises a steel pipe 1, an FRP pipe 3 and a block coal gangue concrete 4, and the inner diameter of the steel pipe 1 is greater than the outer diameter of the FRP pipe 3. , the outer diameter of the FRP pipe 3 in this embodiment is 20 mm smaller than the inner diameter of the steel pipe 1, the top of the FRP pipe 3 protrudes from the steel pipe 1, the height of the FRP pipe 3 is 100 mm higher than the steel pipe 1, and the inside of the steel pipe 1 passes through the positioner 5 The FRP pipe 3 is fixed, and the outer side of the steel pipe 1 is welded w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com