Raw material sand treatment device for producing concrete

A technology for sand treatment and concrete is applied in the field of raw material sand treatment devices for producing concrete, which can solve problems such as lack of heating effect, and achieve the effects of improving stirring and heating effects, drying effects, and heating effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

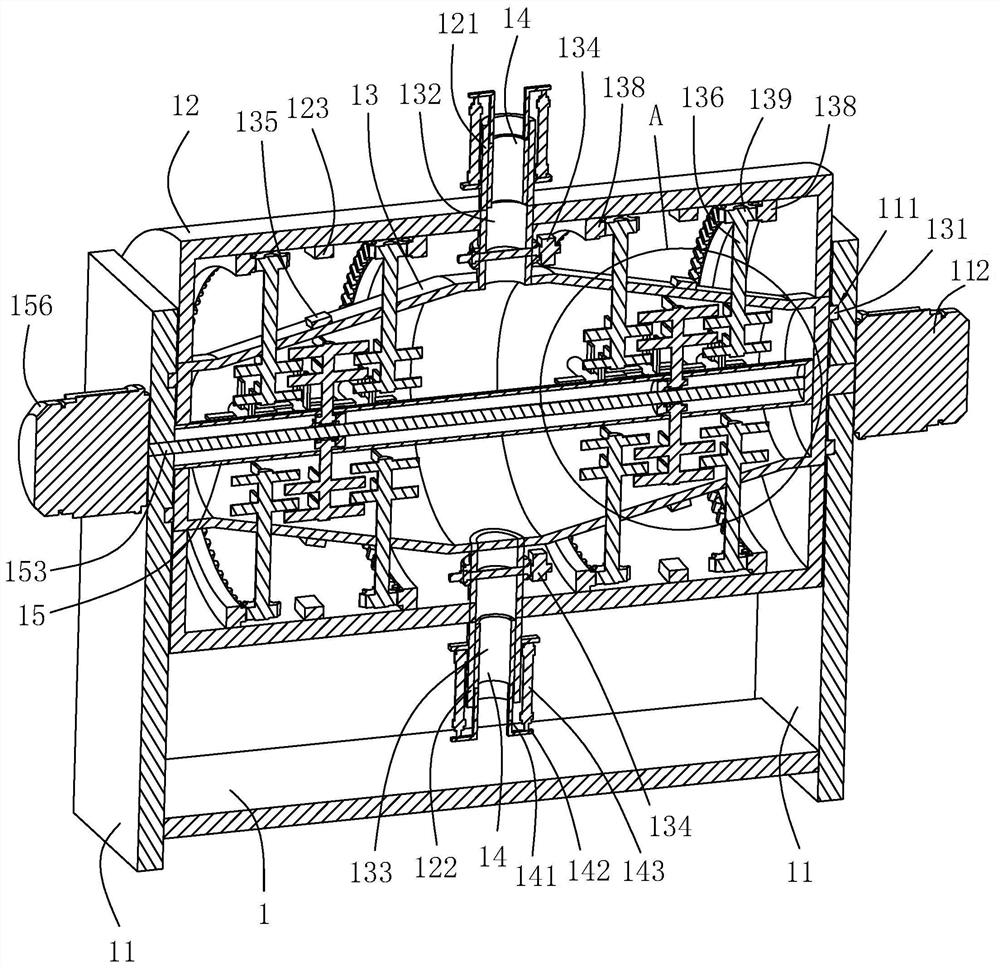

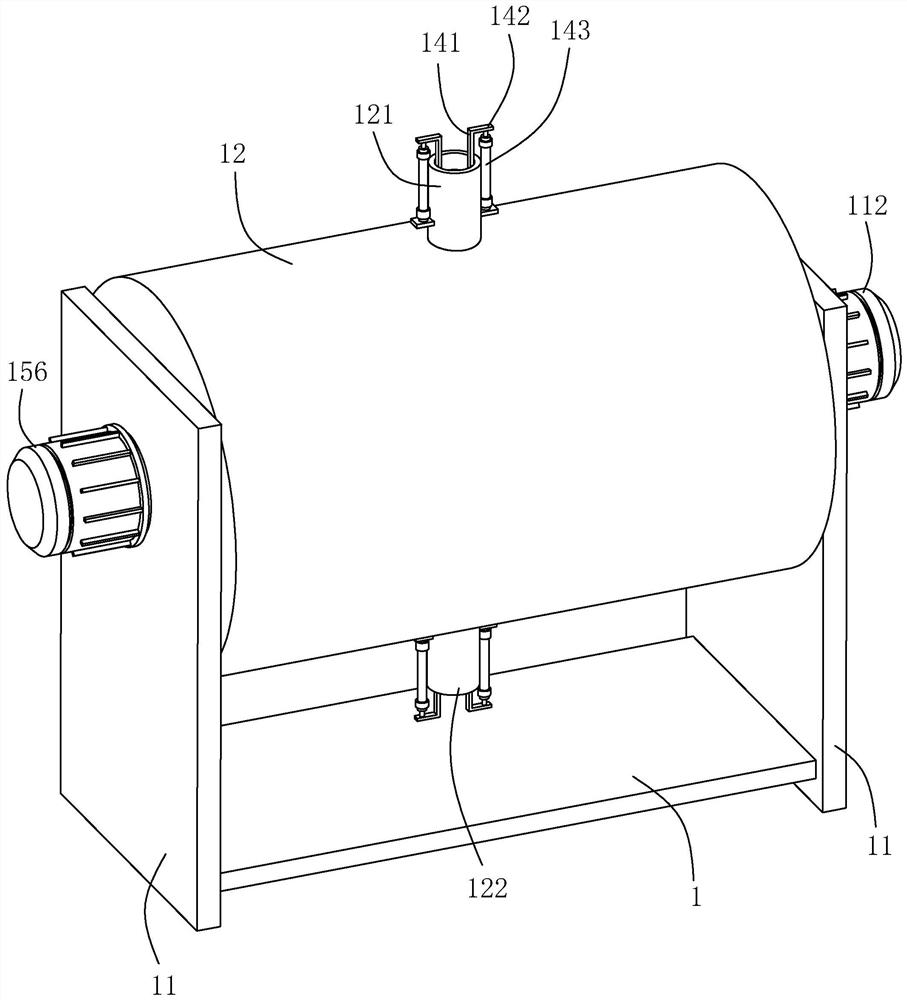

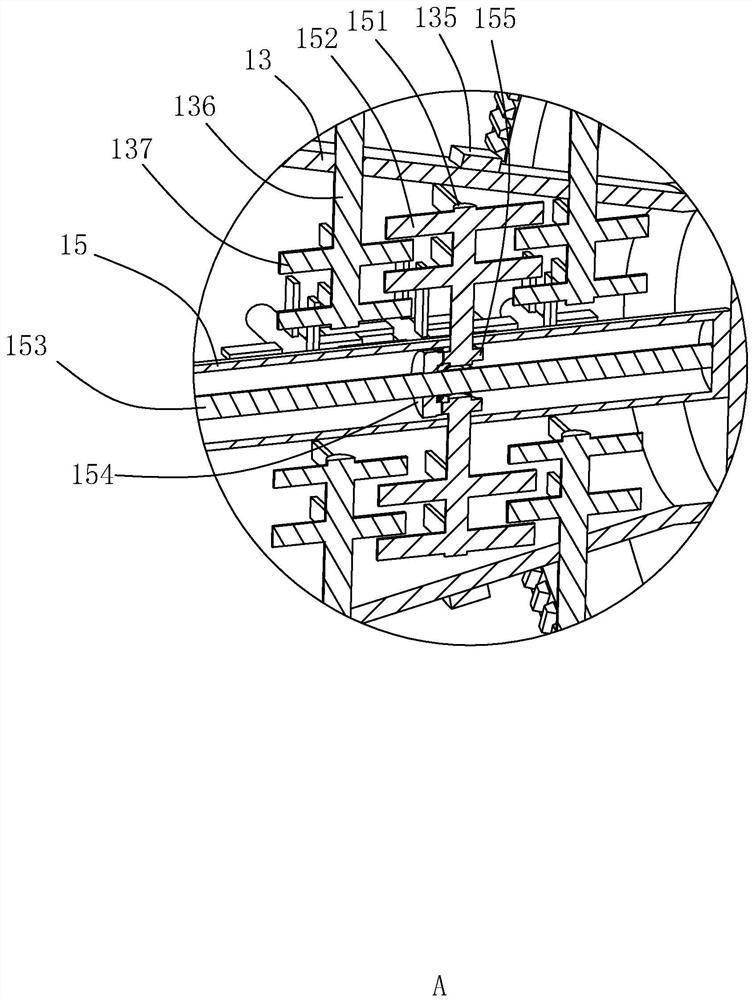

[0031] The following is attached Figure 1-3 The application is described in further detail.

[0032] The embodiment of the present application discloses a raw material sand processing device for producing concrete. combine figure 1 and figure 2 , a raw material sand processing device for concrete production, comprising a bottom plate 1, side plates 11 are arranged on the bottom plate 1 and on both sides of the bottom plate 1, an outer cylinder 12 is fixedly arranged between the side plates 11 on both sides, and the side plates 11 on both sides An inner cylinder 13 located in the outer cylinder 12 is rotated between them, and the diameter of the inner cylinder 13 gradually decreases from the two ends toward the middle; the two end faces of the outer cylinder 12 are provided with openings for the inner cylinder 13 to pass through. The opposite surfaces of the side plates 11 are provided with rotating grooves 111 in the circumferential direction, and the inner cylinder 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com