Multi-layer split type balance gun filling system and method

A split and balanced technology, applied in launching devices, offensive equipment, ammunition supply, etc., can solve the problems of increasing the difficulty of manual loading, increasing the loading time, quality, and size, shortening preparation time, and ensuring simplicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

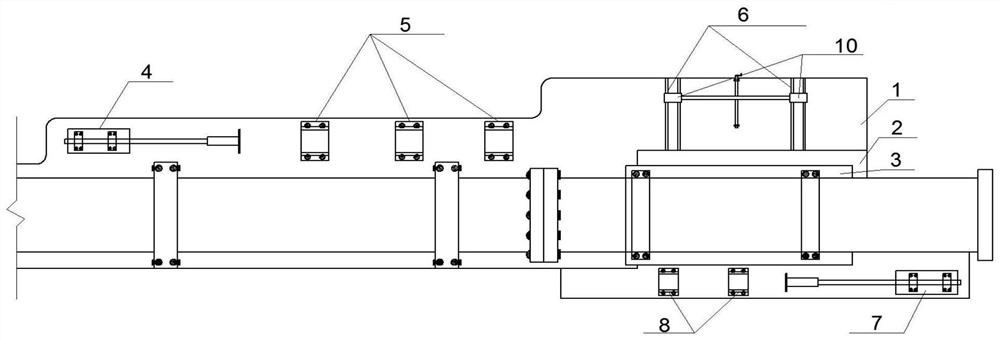

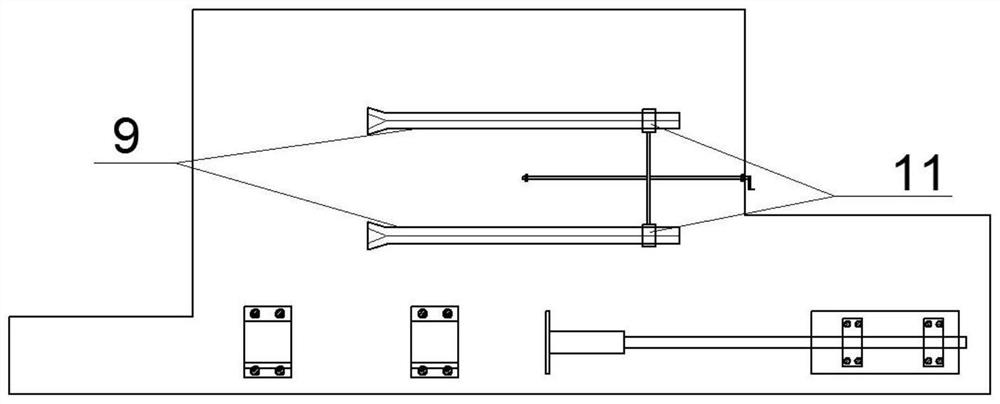

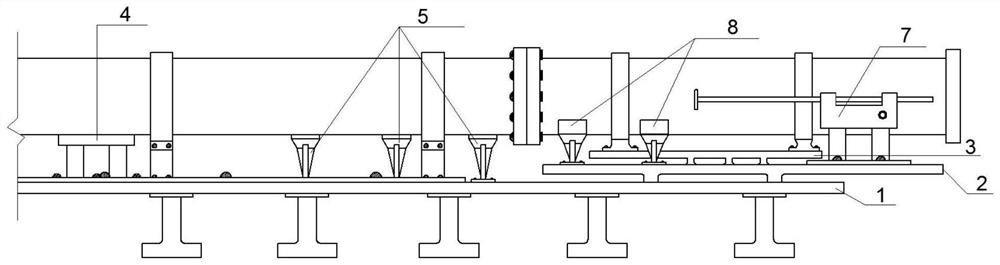

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] combine Figure 1-3 , it can be seen that the ammunition loading system of the large-caliber split-type balanced gun of the present invention mainly includes: the front barrel of the balanced gun, the rear barrel of the balanced gun, and the electric propulsion system 4, 5 of the balanced body, wherein 4 electric push rods of the balanced body , 5 is the support frame of the balance body, the electric propulsion system 4,5 of the balance body is installed on the lower base 1, and will not move; the electric propulsion system 7,8 of the projectile and propellant powder is installed on the middle base 2, The base 2 moves and moves; the separation and fixed connection systems 1, 2, 3, 6, 9, wherein the lower base 1, the guide rail 6 and the middle base 2 form a radial separation device, and the middle base 2, the guide rail 9 and the upper base The base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com