Global overtemperature monitoring and temperature control auxiliary system for plate heater

An auxiliary system and heater technology, applied in the field of wind tunnel testing, can solve problems such as large human error, insulation layer falling off, breaking, etc., and achieve the effects of saving installation space, ensuring safe use, and avoiding an excessively large field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below in conjunction with embodiment.

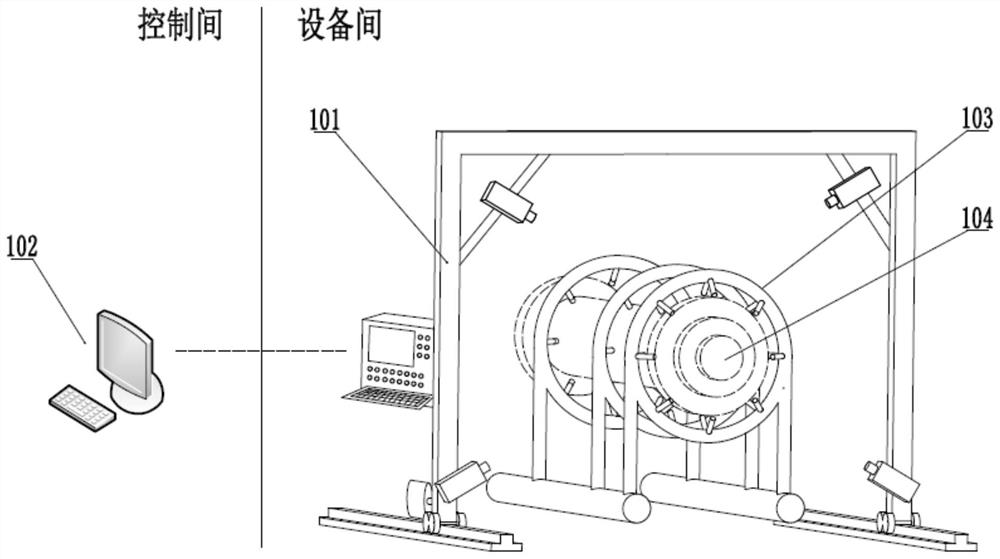

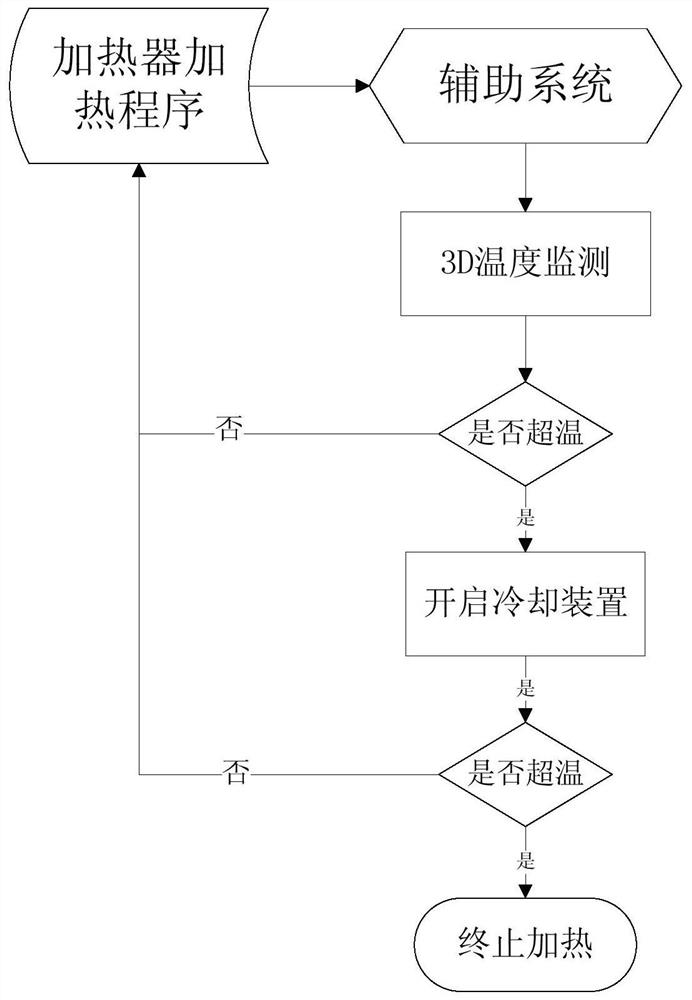

[0036] A global over-temperature monitoring and temperature control auxiliary system for plate heaters, such as figure 1 As shown, it includes an infrared global temperature measurement unit 101, an over-temperature control unit 102 and a cooling unit 103,

[0037] The infrared global temperature measurement unit 101 uses infrared camera to measure the overall temperature of the heater;

[0038] The over-temperature control unit 102 identifies the temperature collection data, and issues an over-temperature alarm to realize auxiliary control of heater operation;

[0039] The cooling unit 103 is connected to the original air source of the wind tunnel, and the cold blowing ring and the cooling nozzle realize the gas flow on the surface of the heater shell, thereby realizing the cooling of the heater shell;

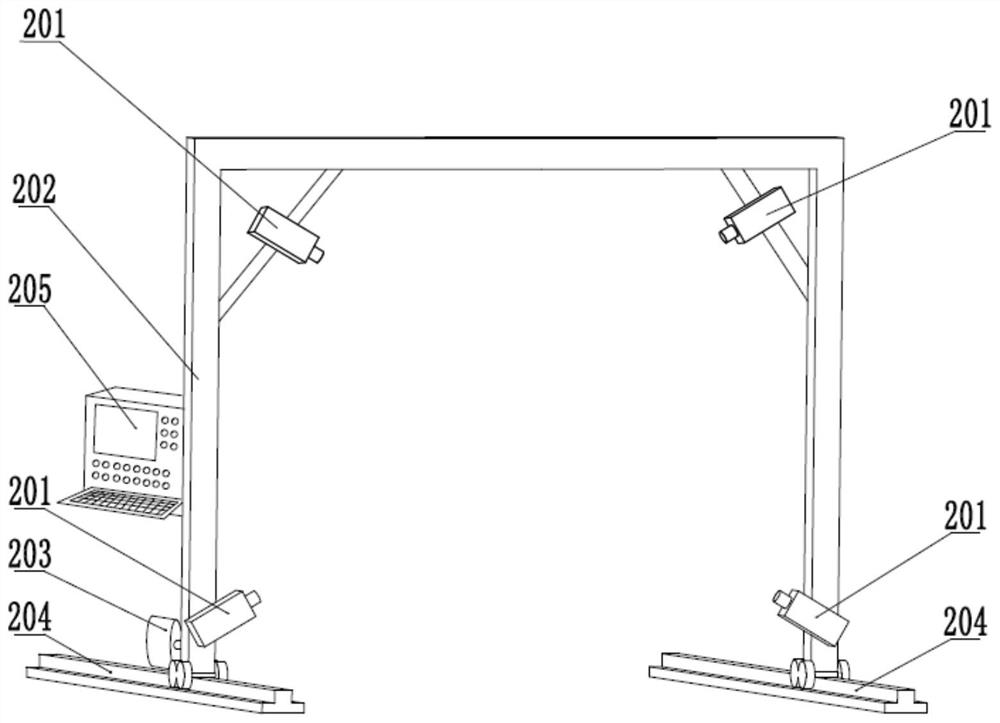

[0040] Such as figure 2 As shown, the infrared global temperature measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com