A self-sensing elastic energy storage and ejection release test device for superelastic memory alloy wire

A technology of memory alloy wire and elastic energy, which is applied in the direction of measuring device, using stable tension/pressure to test the strength and strength characteristics of materials, and can solve the problem of lack of energy storage and release performance of test devices and inability to superelastic memory alloy wire Test and other issues to achieve the effect of easy replacement and clear relative positional relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings:

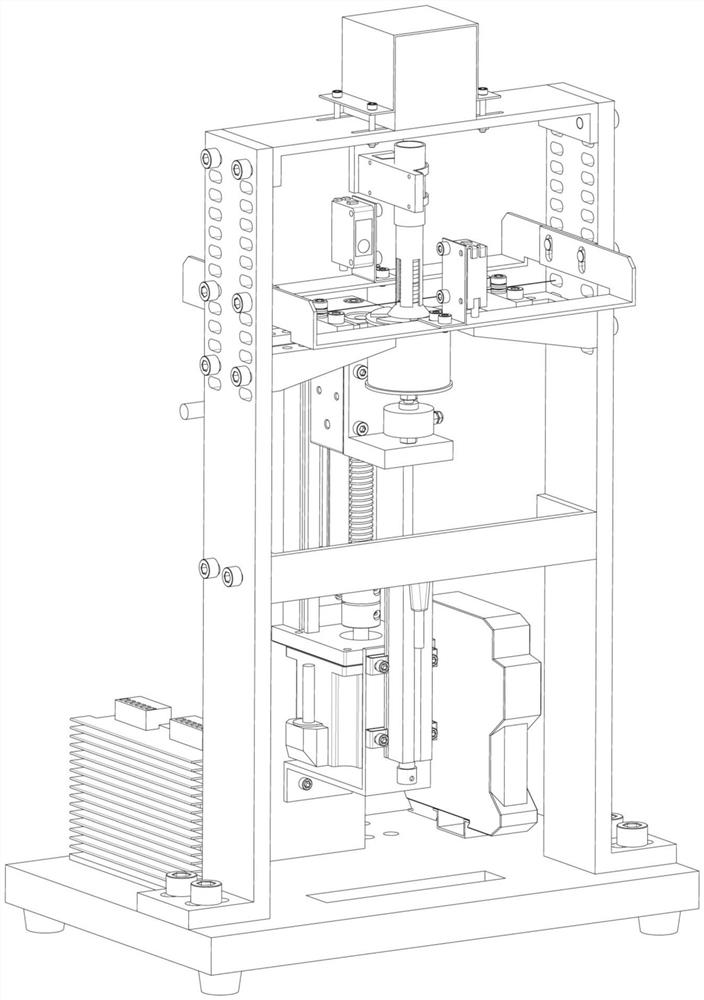

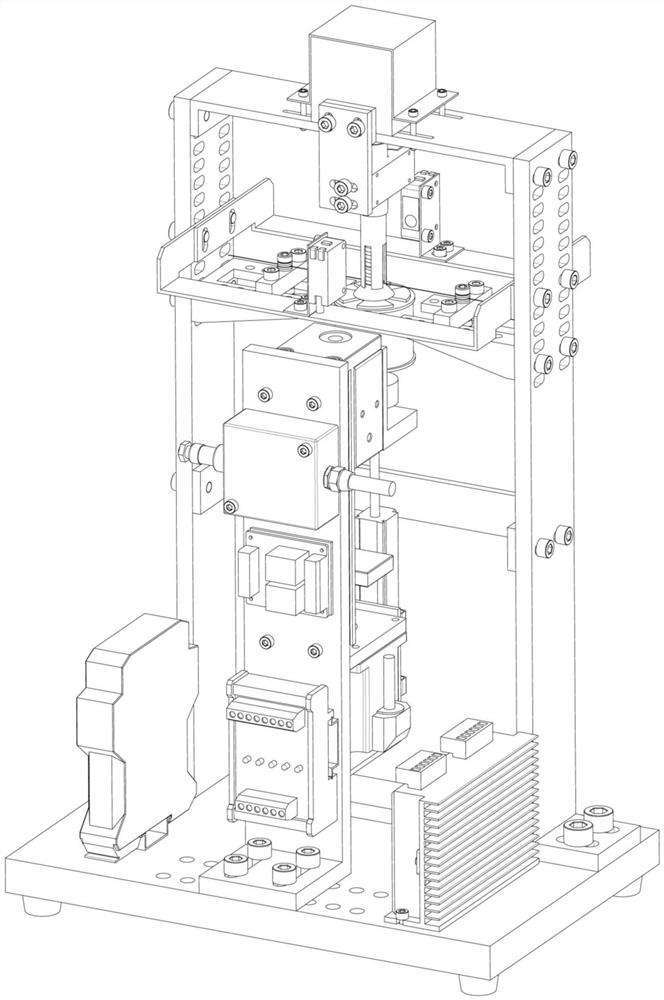

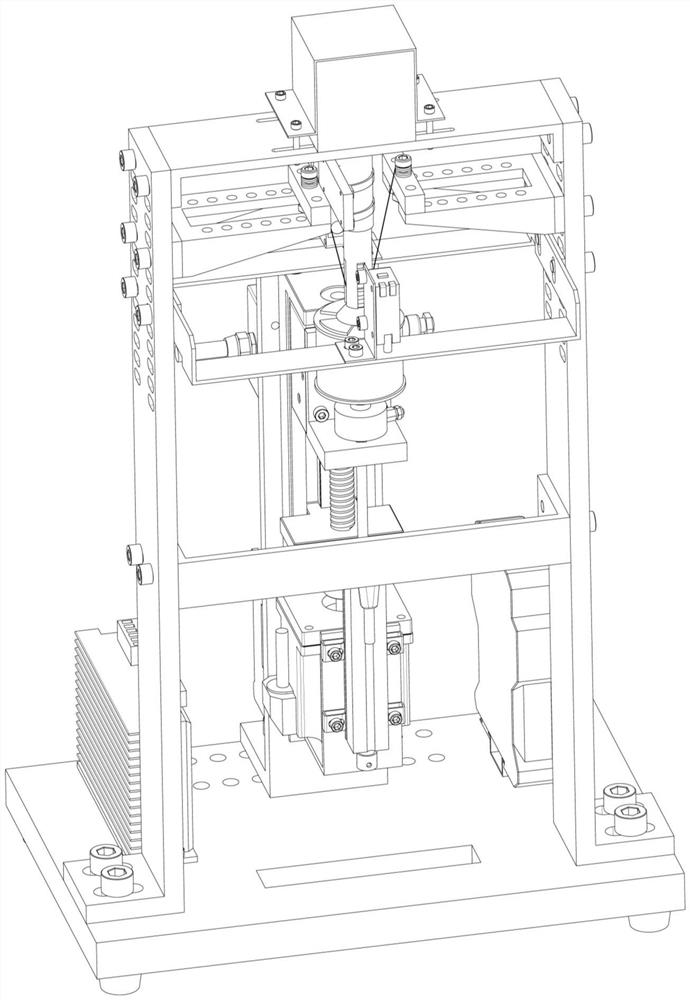

[0023] Reference attached Figure 1-10 , the device is a superelastic memory alloy wire self-perceived elastic energy storage and ejection release test device. It consists of bottom plate (101), gantry vertical plate (102), sliding table vertical plate (103), upper beam (109), lower beam (105), laser sensor bracket (106), electronic ruler bracket (104), target foam board (1011), target foam board clamp (1010), conduit (107), conduit clamp (108), connecting frame (201), bakelite connecting block (202), clamping bolt (203), clamping nut (205) , stepper motor (301), stepper motor driver (401), slide table (302), force sensor connection board (303), electromagnet (305), relay (404), projectile (306), resistance signal conditioning device (403), spring self-resetting electronic ruler (406), force sensor (304), transmitter (405), signal conversion module (402), laser senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com