Belt detection algorithm based on machine vision

A detection algorithm and machine vision technology, applied in the direction of instrumentation, calculation, image data processing, etc., can solve problems such as false detection, large missed detection, inability to detect small belt tears, unsuitable for industrial use, etc., to achieve fast processing speed, The output precision is improved and the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] In embodiment one, add following embodiment again:

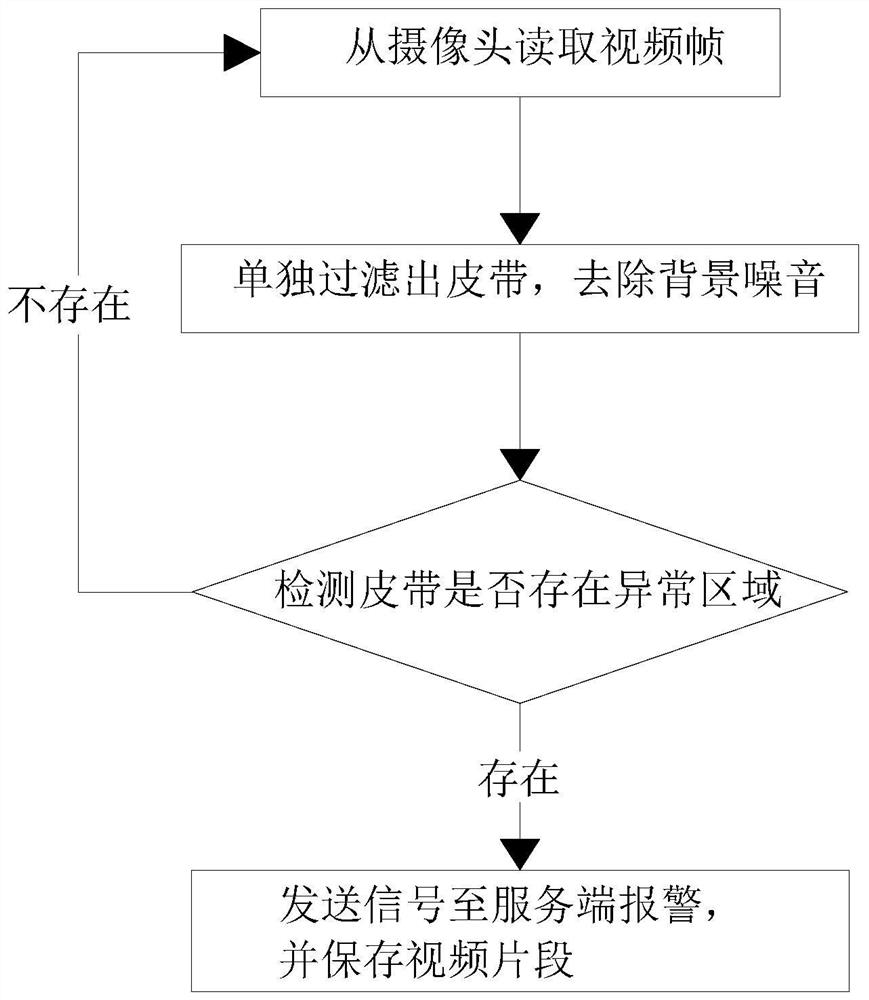

[0039] A kind of belt detection algorithm based on machine vision, comprises the steps:

[0040] A. First read the video frame through the camera;

[0041] A1. Collect the surface image of the belt surface through the camera, and judge the clarity of the collected image, and adjust the focus state according to the clarity of the image;

[0042] B. Separately filter out the belt and remove background noise;

[0043] B1. Separately extract the moving belt for processing, perform regional recognition features on abnormal images such as tears, and identify those that meet the set threshold as tears;

[0044] C. Detect whether there is an abnormal area in the belt;

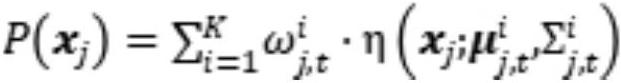

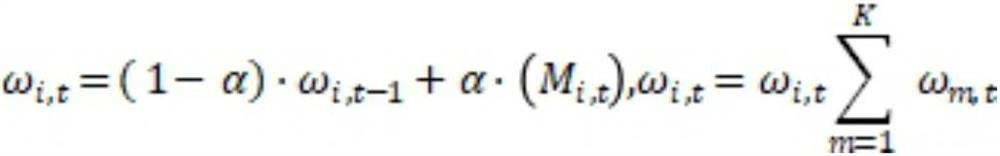

[0045] C1. Select the previous most likely models as background models. After the background model is extracted, the belt can be filtered out for separate detection;

[0046] D. Send a signal to the server to alarm and save the video clip;

[0047] D1. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com