Cylindrical battery, battery module and battery pack

A cylindrical battery technology, applied to battery pack parts, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of increasing pre-positioning errors, large heat generation, battery thermal runaway, etc., to increase the conductivity of the negative electrode Efficiency, increased space utilization, and the effect of preventing thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

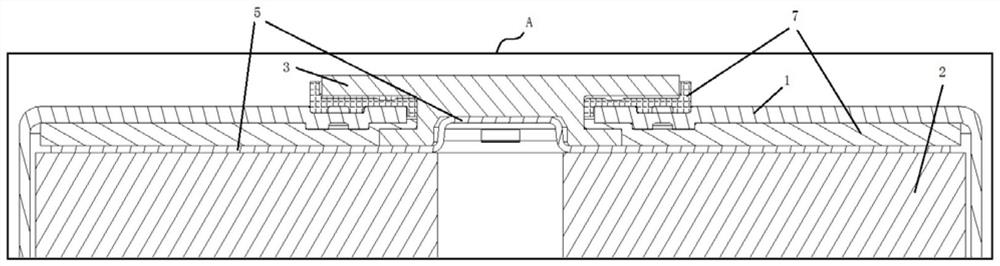

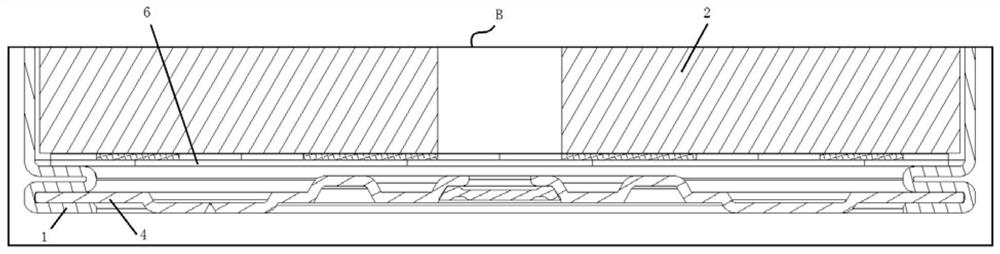

[0053] Such as Figure 1-3 As shown, this embodiment provides a cylindrical battery, including a casing 1 , a cell 2 , a pole 3 , a cover plate 4 , a positive current collector 5 , a negative current collector 6 and an insulating seal 7 . The shell 1 is a cylindrical tank structure, and the battery cell 2, the positive electrode collector plate 5, and the negative electrode collector plate 6 are all arranged inside the shell 1, and the battery cell 2, the electrolyte solution, and the positive electrode current collector plate are arranged inside the shell 1. Disk 5 and negative current collector disk 6.

[0054] The notch connection between the cover plate 4 and the housing 1, the connection structure between the cover plate 4 and the housing 1 and the cap and cylindrical lithium battery disclosed in the existing Chinese patent CN200620014774.0 (cylindrical lithium battery combined cap and battery) The connection structure of the housing of the ion battery is the same, but i...

Embodiment 2

[0061] Such as Figure 4-6 As shown, this embodiment provides a cylindrical battery, including a casing 1, a battery cell 2, a pole 3, a cover plate 4, a positive collector plate 5, a negative collector plate 6, an insulating seal 7 and a sealing rubber ring 8. The difference between the cylindrical battery provided in this embodiment and the cylindrical battery provided in Example 1 at least includes: in the cylindrical battery provided in this embodiment, the cover plate 4 is connected to the notch of the casing 1, and the periphery of the cover plate 4 is connected to the casing 1. The body 1 is sealed and fixedly connected by the sealing rubber ring 8, the sealing rubber ring 8 covers the periphery of the cover plate 4, and the outer surface of the casing 1 is pressed inward by the sealing rubber ring 8 to compact and seal the sealing rubber ring 8 and the cover plate 4 , Only the cover plate, the sealing rubber ring 8 and the housing participate in the sealing part.

[...

Embodiment 3

[0064] Such as Figure 7-9 As shown, this embodiment provides a cylindrical battery, including a casing 1, a cell 2, a pole 3, a cover plate 4, a positive current collector 5, a negative current collector 6, an insulating seal 7, and a rigid connector 9.

[0065] The difference between the cylindrical battery provided in this embodiment and the cylindrical battery provided in Embodiment 1 at least includes: the cylindrical battery provided in this embodiment, the notch of the casing 1 and the end face of the cover plate 4 facing the casing 1 are connected by laser welding . The horizontal diameter of the cover plate 4 is equal to the maximum diameter of the housing 1, and the end surface of the cover plate 4 located inside the housing 1 is rigidly connected to the negative electrode collector plate 6, that is, the cover plate 4 supports the negative electrode current collector through a rigid connector 9 The disc 6 , that is, the cover plate 4 fixes and supports the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com