Personal care composition with increased vapor release

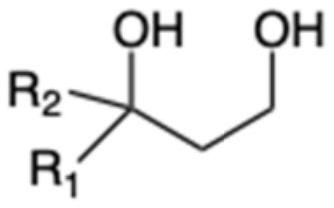

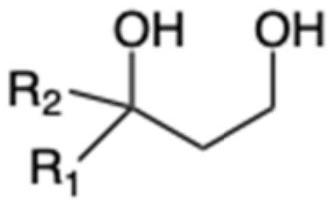

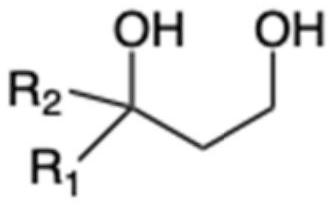

A personal care and composition technology, which is applied in the direction of drug combination, skin care preparations, active ingredients of hydroxyl compounds, etc. It can solve the problems of affecting the appearance, distribution of olfactory composition, reducing physical stability, increasing the content of olfactory composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0118] Examples C-F contain C72, a microcrystalline wax exhibiting a penetration of about 35 dmm to about 75 dmm at 25°C. When 5% (Example C) and 10% (Example D) When C72 was added to the composition, the firmness parameters increased to acceptable levels and the instability index decreased compared to the 2x control, while the mean vapor release remained similar to the 2x control. Although hardening the composition, the addition of microcrystalline wax in Examples C and D did not prevent vapor release. However, at about 20% and 30% as in Examples E and F, respectively At C72, the firmness parameter increased to over 238 g.sec and the average vapor release at 8 hours decreased to a level significantly lower than the 2x control.

[0119] Examples G and H contain X-145 AH, a second microcrystalline wax exhibiting a needle penetration of about 35 dmm to about 75 dmm at 25°C. When 5% (Example G) and 10% (Example H) When X-145AH was added to the composition, the firmness...

Embodiment A-B

[0134] Examples A-B were prepared according to the following procedure:

[0135] First, place the water bath ( Werke LT6( Wilmington, NC) or equivalent) connected to the main reaction vessel ( Werke LR-2000V Lab Reactor or equivalent) and set the water bath to 60.0°C. Measure petroleum jelly and transfer it to the main reaction vessel using a spatula. Reweigh the petroleum jelly to ensure accurate addition. Then, lower the lid and set the stirrer to 60 RPM. The vessel was heated to a jacket set point temperature of 60.0°C (corresponding to a reaction vessel temperature of 60°C ± 1°C) until the mixture was completely melted.

[0136] While mixing in the main reaction vessel, a premix of olfactory agents was prepared. First, camphor and thymol were added to a premix beaker. Grind the menthol crystals with a pestle and mortar and add to the premix beaker. Add turpentine, eucalyptus, and cedar wood oil to the premix beaker in sequence. Insert a magnetic stir bar into...

Embodiment W-X

[0158] Examples W-X were prepared according to the following procedure

[0159] First, place the water bath ( Werke LT6( Wilmington, NC) or equivalent) connected to the main reaction vessel ( Werke LR-2000V Lab Reactor or equivalent) and set the water bath to 85.0°C. Measure petroleum jelly and add-on wax and transfer them to the main reaction vessel using a spatula. Reweigh the petroleum jelly and add-on wax to ensure accurate addition. Then, lower the lid and set the stirrer to 60 RPM. The vessel was heated to a jacket set point temperature of 85.0°C (corresponding to a reaction vessel temperature of 85°C ± 1°C) until the mixture was completely melted.

[0160] On a separate hot plate, add EB-21, GP-1, and 3-methyl-1,3-butanediol to a second container and stir to induce a vortex. The mixture was heated to 95°C-100°C while stirring using a magnetic stir bar until completely transparent with no visible particles to form a gelling agent mixture.

[0161] When both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com