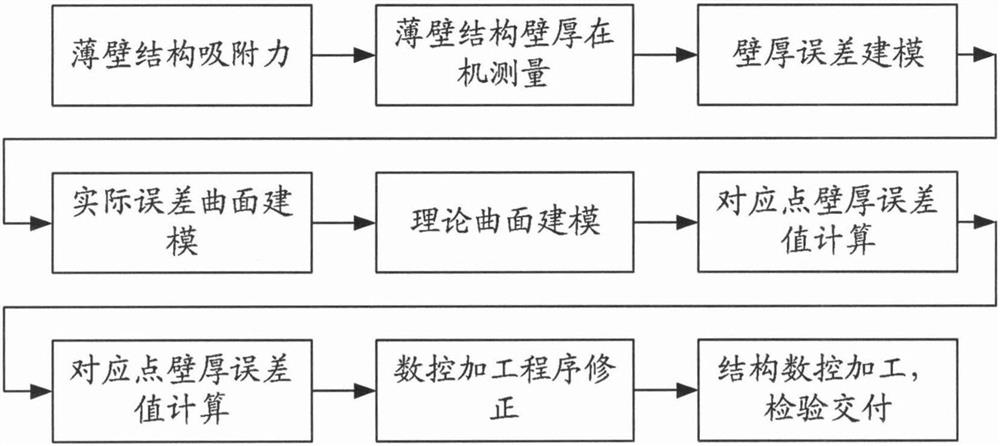

A Machining Error Compensation Method for Complicated Thin-walled Structures

A technology of thin-walled structure and compensation method, applied in measuring devices, instruments, etc., can solve the problems of excessive wall thickness and low machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Taking the processing of thin-walled parts as an example below, the present invention will be further described in detail in conjunction with the accompanying drawings and examples.

[0023] Step 1: The negative pressure obtained by the vacuum pump is generally 0.07MPa, which can be multiplied by the surface area of the part to obtain the adsorption force, and multiplied by the static friction coefficient to obtain the static friction force.

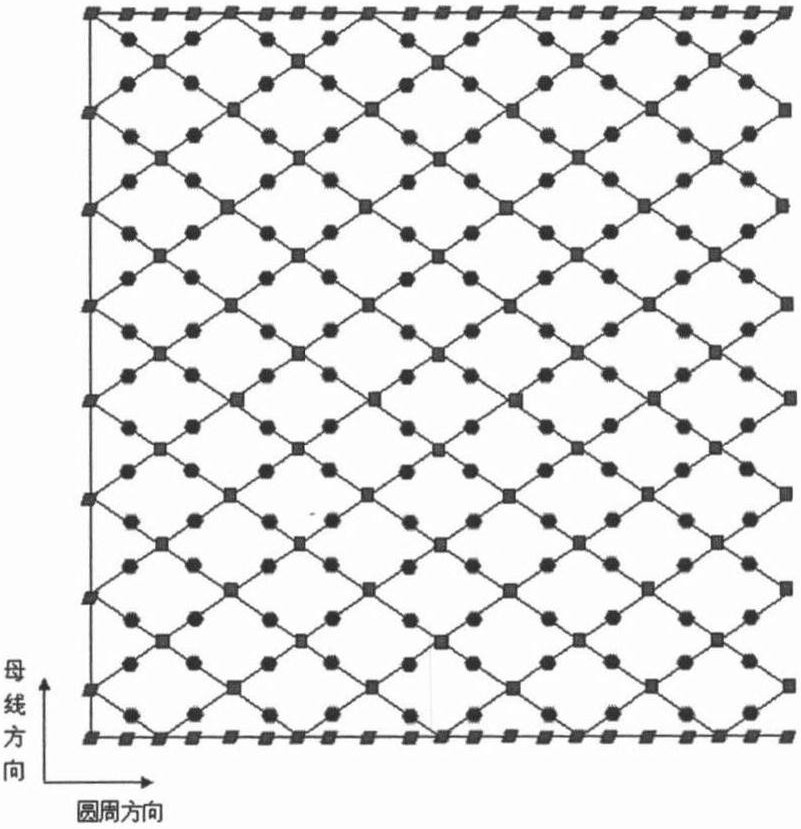

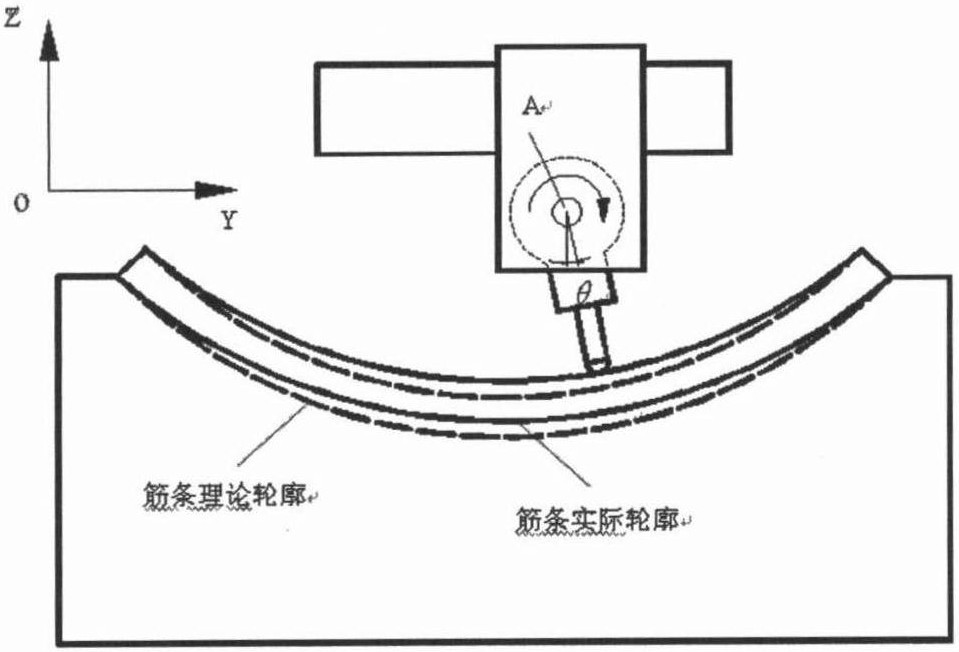

[0024] Step 2, measuring point planning according to figure 2 with image 3 When measuring, follow the direction of the generatrix first and then the direction of the circumference. The measurement points on the same bus line are one group during measurement, and the measurement result should be the contour deviation of each group of corresponding points planned, so the radial error Δδ of this position can be calculated, and the error value Δδ can be theoretically considered as the workpiece in The positioning error at this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com