Method for preparing excellent planting soil by utilizing gravelly sand, gravel aggregate dewatered sludge and kitchen waste

A technology for dewatering sludge and kitchen waste, applied in the field of soil science, can solve the problems of unsuitable plant growth and development, endangering the living environment, low biological production, etc., and achieves loose structure and ventilation, high economic benefits, and conditioning soil structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

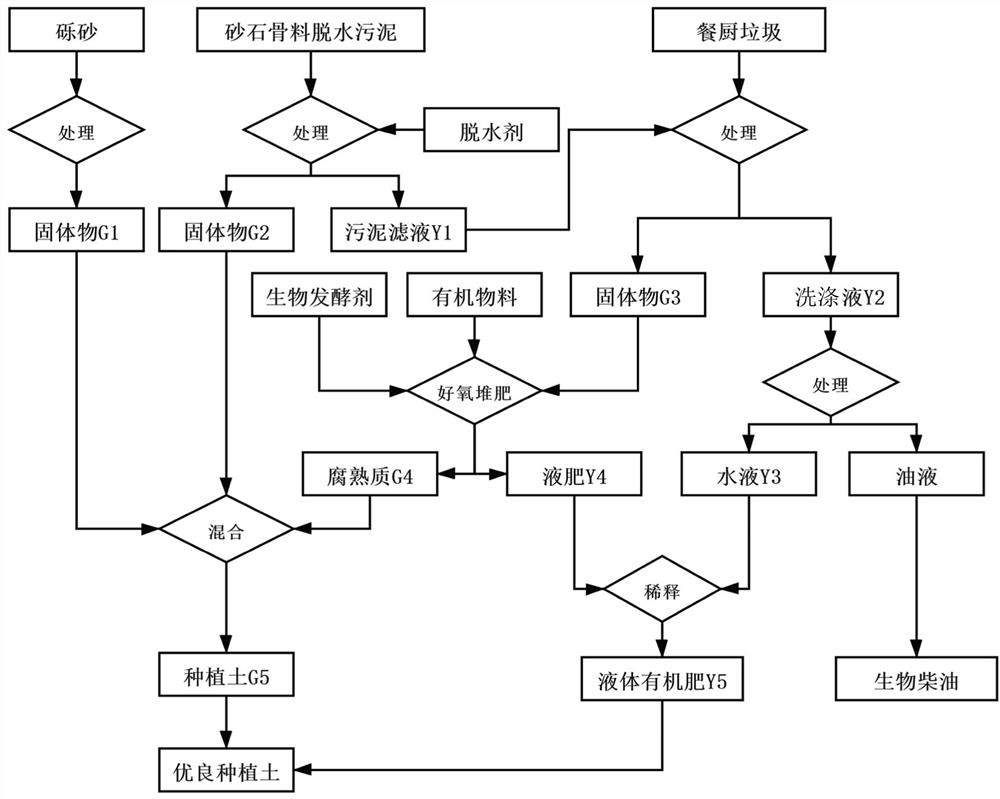

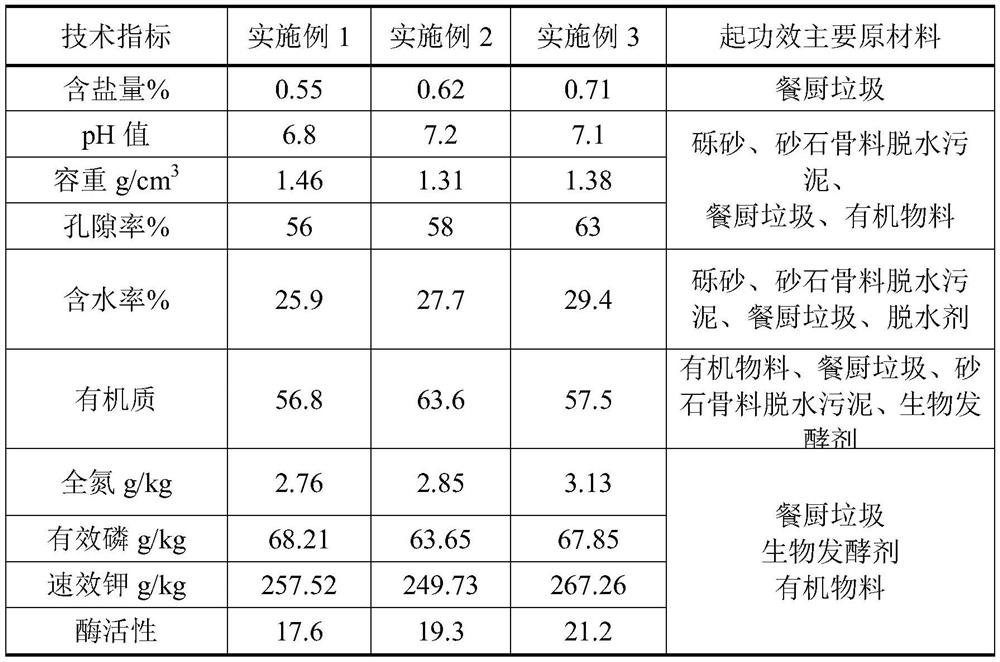

[0040] A method for preparing high-quality planting soil by utilizing gravel sand, sandstone aggregate dewatered sludge, and kitchen waste, comprising the following steps:

[0041] Step 1, gravel treatment: removing larger gravel and sundries, passing through a 5-mesh sieve, taking the undersieve and controlling its moisture content to 8%, to obtain granular solid G1.

[0042] Step 2, sand and gravel aggregate dewatered sludge treatment: add a dehydrating agent with a mass of 6% of the completely dried sludge, and perform solid-liquid separation on the sand and gravel aggregate dewatered sludge to obtain a powdery solid G2 with a moisture content of 8% and sludge filtrate Y1.

[0043] Step 3, kitchen waste treatment: 1) Sorting first, then mechanically crushing; 2) Washing the crushed matter with sludge filtrate Y1 to obtain solid matter G3 and washing liquid Y2, the maximum particle size of solid matter G3 is 15mm; 3) Washing After liquid Y2 is separated from oil and water b...

Embodiment 2

[0047] A method for preparing high-quality planting soil by utilizing gravel sand, sandstone aggregate dewatered sludge, and kitchen waste, comprising the following steps:

[0048] Step 1, gravel treatment: remove larger gravel and sundries, pass through a 5-mesh sieve, take the under-sieve and control its moisture content to 10%, to obtain granular solid G1.

[0049] Step 2, treatment of sand aggregate dewatered sludge: adding a dehydrating agent with a mass of 8% of the completely dried sludge, performing solid-liquid separation on the sand aggregate dewatered sludge, and obtaining a powdery solid G2 with a water content of 10% and sludge filtrate Y1.

[0050] Step 3, kitchen waste treatment: 1) Sorting first, then mechanically crushing; 2) Washing the crushed matter with sludge filtrate Y1 to obtain solid matter G3 and washing liquid Y2, the maximum particle size of solid matter G3 is 20mm; 3) Washing After liquid Y2 is separated from oil and water by gravity settling, the...

Embodiment 3

[0054] A method for preparing high-quality planting soil by utilizing gravel sand, sandstone aggregate dewatered sludge, and kitchen waste, comprising the following steps:

[0055] Step 1, gravel treatment: remove larger gravel and sundries, pass through a 5-mesh sieve, take the undersieve and control its moisture content to 9%, to obtain granular solid G1.

[0056] Step 2, sand and gravel aggregate dewatering sludge treatment: add a dehydrating agent with a mass of 7% of the completely dried sludge, and perform solid-liquid separation on the sand and gravel aggregate dewatering sludge to obtain a powdery solid G2 with a moisture content of 9% and sludge filtrate Y1.

[0057] Step 3, kitchen waste treatment: 1) Sorting first, then mechanically crushing; 2) Washing the crushed matter with sludge filtrate Y1 to obtain solid matter G3 and washing liquid Y2, the maximum particle size of solid matter G3 is 17mm; 3) Washing After liquid Y2 is separated from oil and water by gravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com