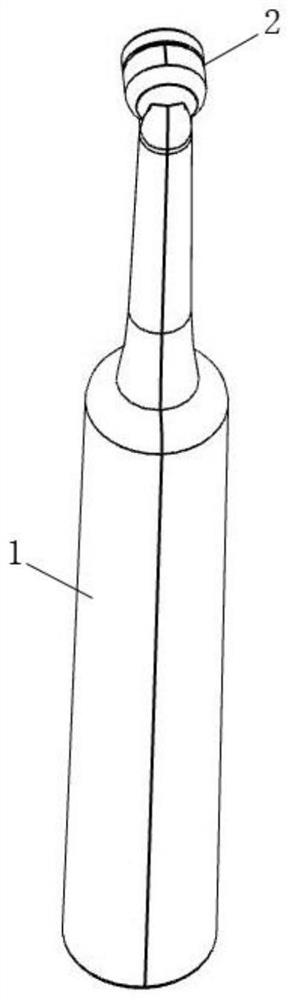

Electric toothbrush

An electric toothbrush and brush handle technology, which is applied in dentistry, tooth cleaning, medical science, etc., can solve the problems that the dirt in the teeth gap cannot be cleaned, it is difficult to clean, and the transmission efficiency is low, so as to improve the user experience, The effect of improving transmission efficiency and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

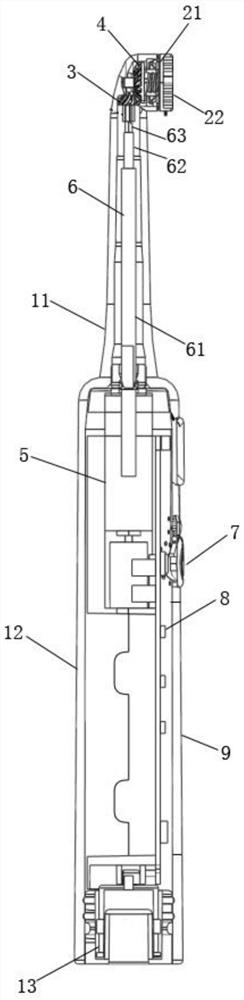

[0024] An electric toothbrush involved in a preferred embodiment of the present invention includes a housing 1, a brush head 2, a first spiral bevel gear 3, a second spiral bevel gear 4 and a drive motor 5, the brush head 2 and the The second spiral bevel gear 4 is connected, the first spiral bevel gear 3 and the second spiral bevel gear 4 are connected in transmission, the first spiral bevel gear 3 is arranged above the driving motor 5 and the first spiral bevel gear A spiral bevel gear 3 is in transmission connection with the drive motor 5, and the central axis of the first spiral bevel gear 3 is perpendicular to the central axis of the second spiral bevel gear 4;

[0025] The drive motor 5 has a stepped shaft 6 connected to the first spiral bevel gear, and the stepped shaft 6 includes a first shaft body 61 , a second shaft body 62 and a third shaft body whose diameter decreases sequentially from bottom to top. body 63, the third shaft body 63 is in transmission connection w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com