Rapid positioning and clamping device for metal cutting machining

A positioning and clamping, metal cutting technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of manpower and material resources, low universality of fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

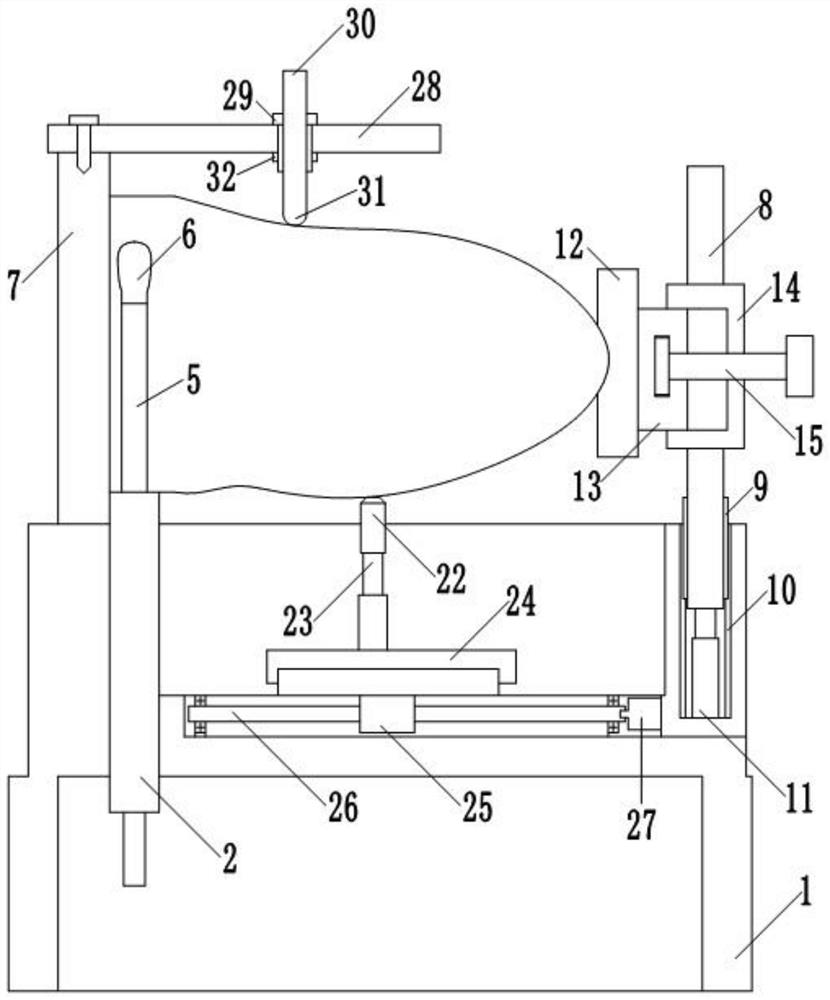

[0048] like figure 1 As shown, the embodiment of the present invention provides a quick positioning and clamping device for metal cutting, including a base 1, the upper surface of the base 1 is fixed with a clamping mechanism for clamping the front and rear sides of the part to be processed, and the upper surface of the base 1 is fixed with a clamping mechanism. A positioning mechanism for pressing the left and right sides of the part to be processed is fixed, and a support mechanism and a pressing mechanism are also fixed on the upper surface of the base 1; On the side, the lower end of the support pin 22 is connected with the telescopic end of the first electric push rod 23, the outer casing of the first electric push rod 23 is connected with the sliding part of the screw slide table 24, and the fixed part of the screw slide table 24 passes through the lateral sliding mechanism Connected with the upper surface of the base 1; the pressing mechanism includes a first plate body...

Embodiment 2

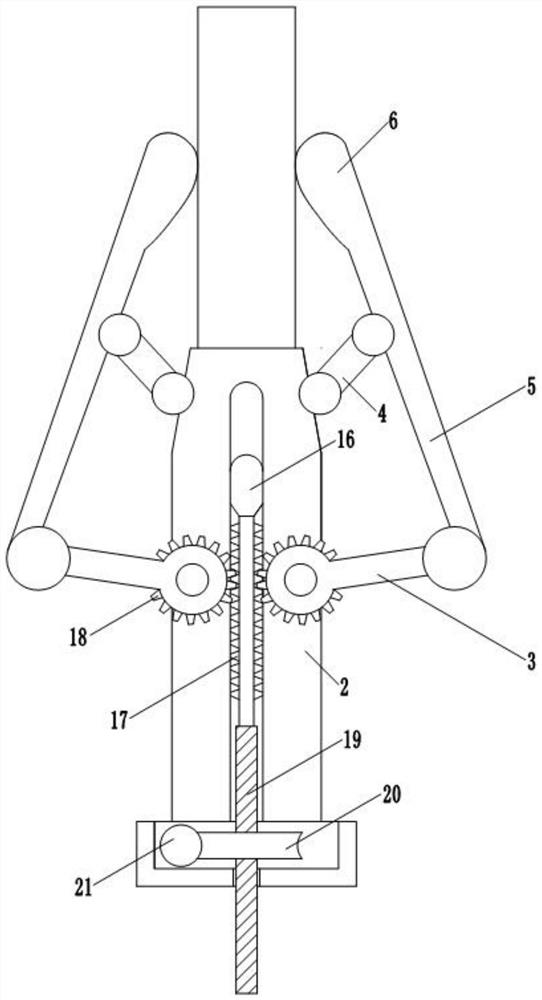

[0051] This embodiment is based on Embodiment 1, and the clamping mechanism includes a second plate body 2 longitudinally extending through a through slot on the left side of the base 1 , and two clamping units are symmetrically hinged on the left and right sides of the second plate body 2 . , each clamping unit includes: an active rocker 3, one end of which is hinged on one side of the second plate body 2; a connecting rod 5, whose lower end is hinged with the other end of the active rocker 3, and its upper end is hinged with the clamping block 6 Fixed connection; the driven rocker 4, one end is hinged to the middle of the connecting rod 5, and the other end is hinged to the second plate body 2; the length of the driven rocker 4 is less than the length of the active rocker 3; A driving mechanism is fixed on the second plate body 2, and the driving mechanism is used to drive the active rockers 3 of the two clamping units to rotate synchronously through the connecting rod 5 to d...

Embodiment 3

[0055] This embodiment is based on Embodiment 2. The positioning mechanism includes a third plate body 7 , a fourth plate body 8 , a second electric push rod 11 , a positioning block 12 and a third screw rod 15 ; the third plate body 7 is fixed on the The upper surface of the base 1 is located on the left side of the second plate body 2 at the same time; the fourth plate body 8 is located on the right side of the base 1, and a slider 9 is fixed on the left and right sides respectively. The longitudinal first chute 10 opened in the groove of the base 1 is slidably connected; the second electric push rod 11 is located below the fourth plate body 8, and its outer casing is fixed in the groove opened by the base 1 Inside, its telescopic end is longitudinally telescopic and is fixedly connected to the bottom of the fourth plate body 8 ; a slider 13 is fixed on the right side of the positioning block 12 . The horizontal second chute 14 is slidably connected; the third screw 15 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com