High-speed cutting and stacking all-in-one machine

An all-in-one, high-speed technology, used in sorting, electrochemical generators, electrical components, etc., can solve the problems of inability to meet the growing demand for battery production, affecting lamination time and production efficiency, and inability to produce quickly. Production speed and production capacity requirements, the effect of improving production efficiency and improving production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

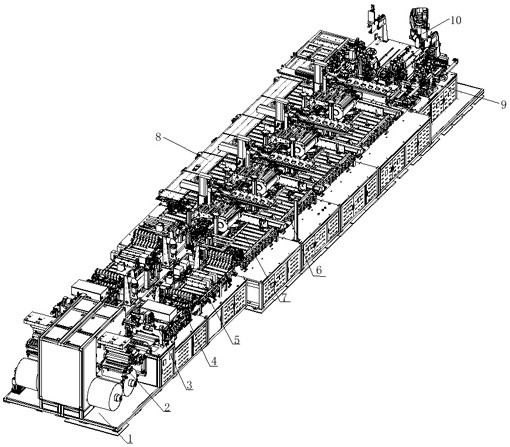

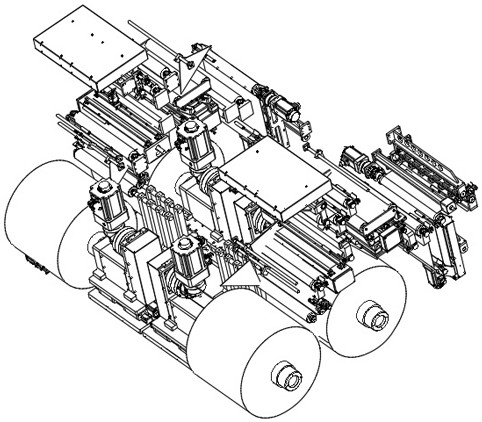

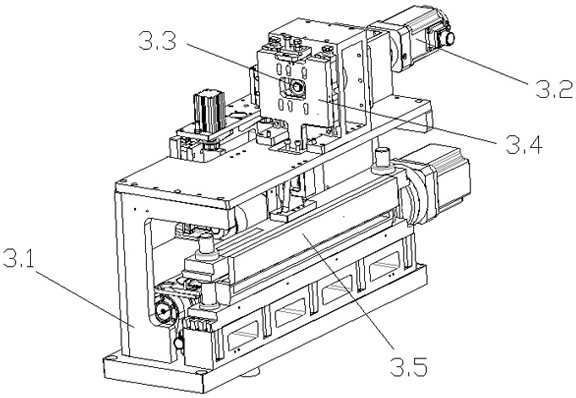

[0047] see Figure 1-20 , the present invention relates to a high-speed cutting and stacking integrated machine, including a frame 1, on which an unwinding mechanism 2, a slicing mechanism 3, a chipping mechanism 4, a high-speed lifting-rotating patching device 5, and a conveying line are arranged. Component 6, stacking mechanism 7, retrieving mechanism 8 and glue-applying mechanism 9, two unwinding mechanisms 2 are arranged on both sides of the front end of the frame 1, and unwind the positive and negative electrode sheet coils respectively; the slicing mechanism 3 is arranged behind the unwinding mechanism 2 to cut the pole piece coil; two conveying line assemblies 6 are provided to transport the sliced positive and negative pole pieces; the chipping mechanism 4 is set behind the slicing mechanism 3, Detect the pole pieces delivered by the conveying line assembly 6, and remove defective products from the conveying line assembly 6; the high-speed lifting-rotating patch devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com