Heavy anti-corrosion powder

A heavy-duty anti-corrosion and anti-corrosion technology, applied in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve problems such as poor adhesion and unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

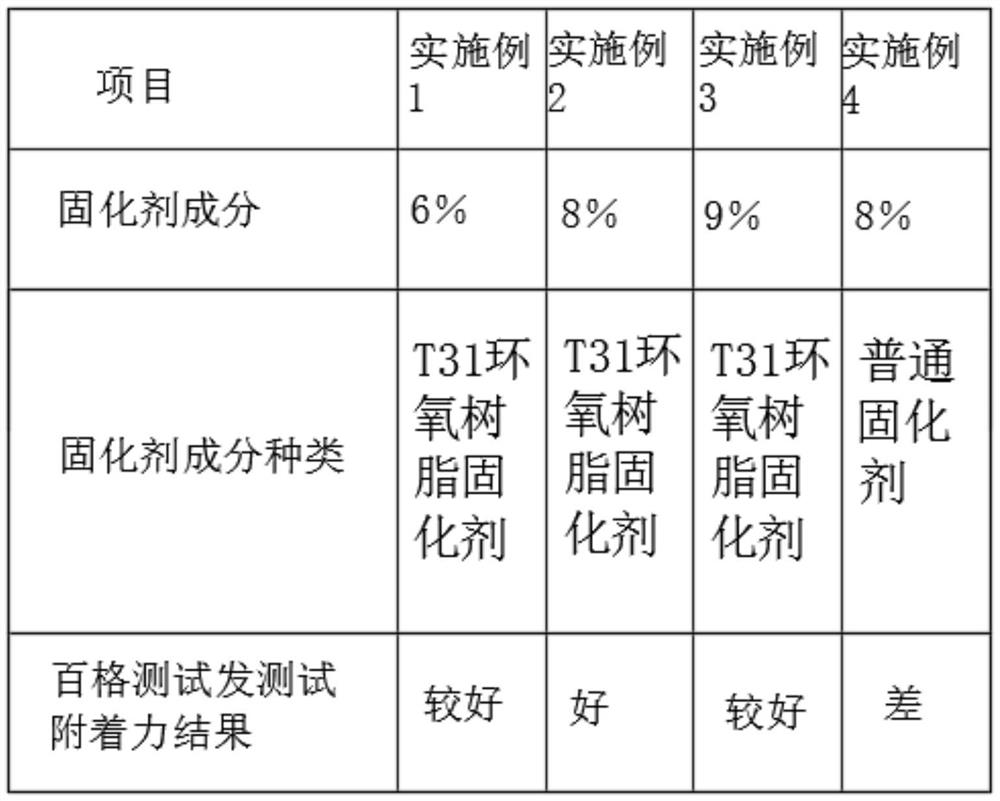

[0023] The embodiment of the present invention provides a technical solution: a heavy-duty anti-corrosion powder, which is composed of the following raw materials in weight percentage: 50% epoxy resin, 6% curing agent, 0.1% dimethylimidazole, 4% auxiliary agent, 9% preservative %, filler 22%, carbon black 0.6%;

[0024] Wherein the preservative is sodium benzoate, the filler is corrugated filler of orifice plate, and the curing agent is T31 epoxy resin curing agent.

[0025] Then follow the steps below to prepare the heavy-duty anti-corrosion powder:

[0026] Step 1. Send the above raw materials into a mixer for stirring, and control the stirring temperature at 80-100°C to obtain a mixture;

[0027] Step 2. Put the mixture obtained in Step 1 into a screw extruder to melt and extrude it, and control the temperature in the feeding section to 70°C, the temperature in the melting section to 90°C, and the temperature in the discharging section to 100°C;

[0028] Step 3, the molte...

Embodiment 2

[0031] The embodiment of the present invention provides a technical solution: a heavy-duty anti-corrosion powder, which is composed of the following raw materials in weight percentage: 52% epoxy resin, 8% curing agent, 0.2% dimethylimidazole, 5% auxiliary agent, 10% preservative %, filler 24%, carbon black 0.8%;

[0032] Among them, the preservative is sodium diacetate, the filler is corrugated filler, and the curing agent is T31 epoxy resin curing agent.

[0033] Then follow the steps below to prepare the heavy-duty anti-corrosion powder:

[0034] Step 1. Send the above raw materials into a mixer for stirring, and control the stirring temperature at 80-100°C to obtain a mixture;

[0035] Step 2. Put the mixture obtained in Step 1 into a screw extruder to melt and extrude it, and control the temperature in the feeding section to 70°C, the temperature in the melting section to 90°C, and the temperature in the discharging section to 100°C;

[0036] Step 3, the molten material ...

Embodiment 3

[0039] The embodiment of the present invention provides a technical solution: a heavy-duty anti-corrosion powder, which is composed of the following raw materials in weight percentage: 55% epoxy resin, 9% curing agent, 0.4% dimethylimidazole, 5.5% auxiliary agent, 11% preservative %, filler 25%, carbon black 0.9%;

[0040] The preservative is propyl benzoate, the filler is a metal pall ring, and the curing agent is T31 epoxy resin curing agent.

[0041] Then follow the steps below to prepare the heavy-duty anti-corrosion powder:

[0042] Step 1. Send the above raw materials into a mixer for stirring, and control the stirring temperature at 80-100°C to obtain a mixture;

[0043] Step 2. Put the mixture obtained in Step 1 into a screw extruder to melt and extrude it, and control the temperature in the feeding section to 70°C, the temperature in the melting section to 90°C, and the temperature in the discharging section to 100°C;

[0044] Step 3, the molten material is pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com