Engineering aluminum alloy material and preparation method thereof

An aluminum alloy material and aluminum alloy technology, applied in metal processing equipment, manufacturing tools, casting equipment, etc., can solve the problems of few external research and development and application, and rarely used, and achieve high mechanical performance indicators, good market prospects, The effect of eliminating intragranular segregation

Pending Publication Date: 2021-09-07

山东国泰铝业有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, it is rarely used in general industrial applications; its processing technology is rarely developed and applied by outsiders.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

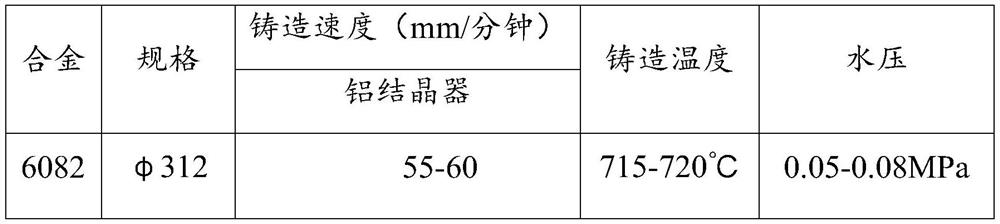

[0024] Processed according to the following process:

[0025] S1 Melting

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

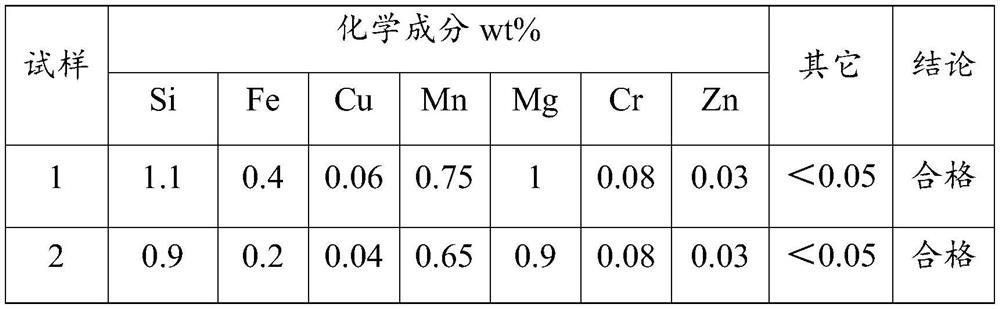

The invention discloses an engineering aluminum alloy material and a preparation method thereof. The engineering aluminum alloy material is prepared from an aluminum alloy blank containing the following elements including 0.65-0.75 wt% of Mn, 0.04-0.06 wt% of cu, 0.9 - 1.1 wt% of Si, and 0.9-1 wt% of Mg. According to the engineering aluminum alloy material, component adjustment of the aluminum alloy material plays a very important role in the mechanical property of a product, and a strengthening phase formed by Al, Si, Mg, Mn and the like in a solid solution of the alloy is the basis of alloy strengthening; and therefore, the ingredient proportion is of great significance to the performance of the final product, repeated adjustment, repeated experiment and strict control must be carried out, and the ingredient proportion is controlled in the minimum range. The casting performance of the alloy can be influenced by an overhigh Mn content, and the higher the Mn content is, the larger the metal flowing viscosity is. Although Cu has the strengthening effect on the alloy, the corrosion resistance can be damaged if the content of the Cu is not strictly controlled, so that appropriate control over the Cu content is also needed.

Description

technical field [0001] The present application relates to an aluminum alloy material for engineering machinery and a preparation method thereof. Background technique [0002] The aluminum alloy material of the present application was mostly used in the fields of national defense industry and the like at the earliest. For example, the hollow girder profile of an aircraft is a product delivered in the T6 state of 6082. Therefore, it is rarely used in general industrial applications; its processing technology is rarely developed and applied by outsiders. In recent years, it has been widely used in many fields such as mine mineral material transmission system, bridge structure materials, transport ship manufacturing, factory building structure, lifting equipment, high-speed rail car structure, railway freight car box structure profiles, and automobile lightweight transformation. The market prospect broad. Contents of the invention [0003] In order to solve the above problem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): C22C21/02C22C21/08C22C1/02C22F1/043C22F1/05B22D43/00B21C23/00B21C25/02

CPCC22C21/02C22C21/08C22C1/026B22D43/004C22F1/002C22F1/043C22F1/05B21C25/02B21C23/001

Inventor 宋从瑞宋钊逸

Owner 山东国泰铝业有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap