Graphene-phenolic resin glue, preparation method thereof and preparation method of outdoor strand woven bamboo floor

A technology of phenolic resin glue and graphene, which is applied in the field of floor manufacturing, can solve problems such as mildew and achieve the effects of prolonging service life, reducing production energy consumption, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

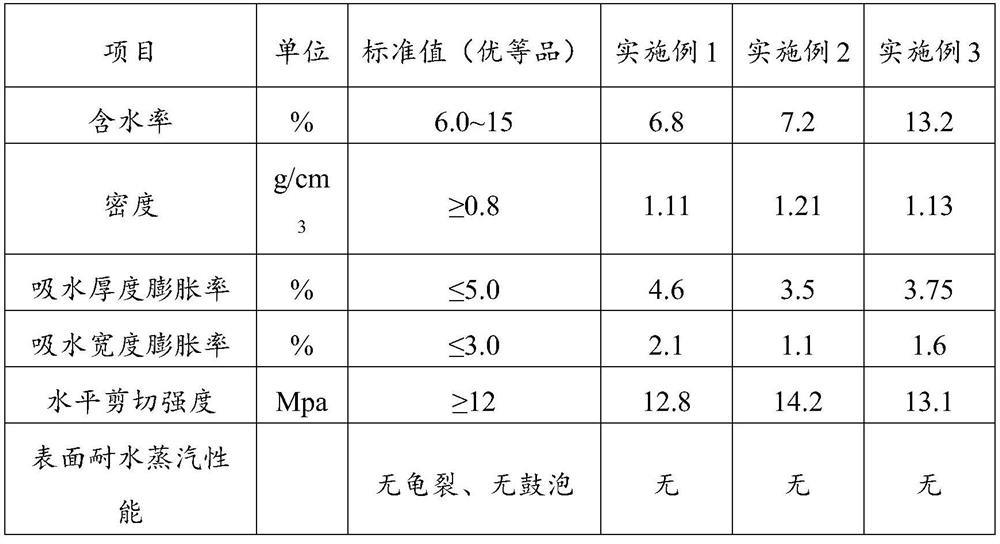

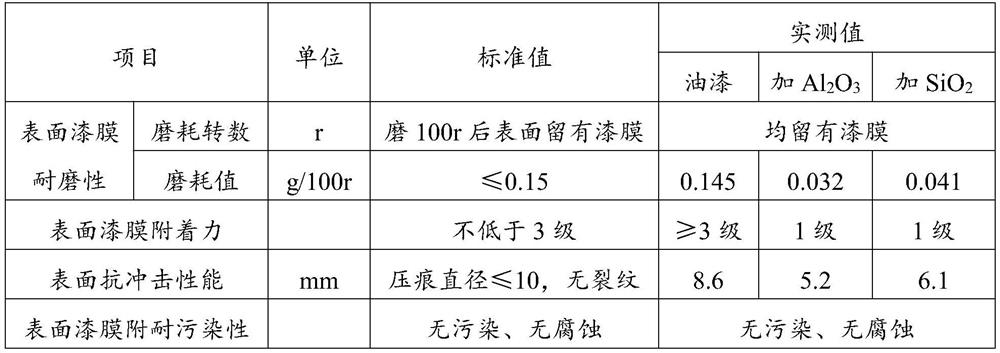

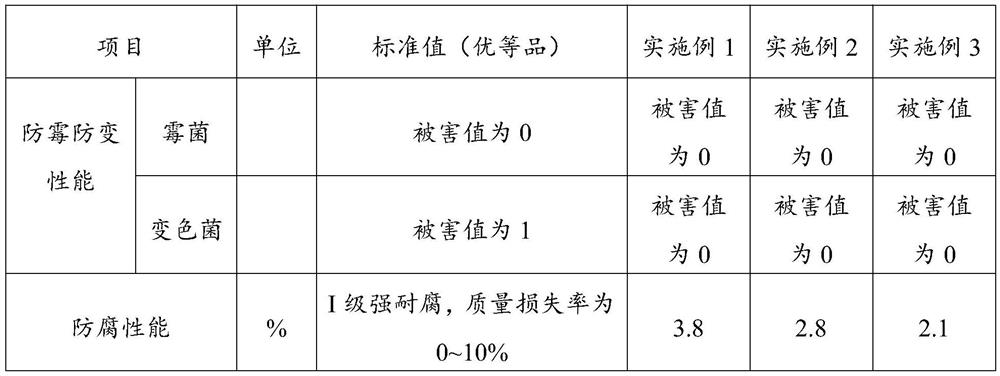

Examples

preparation example Construction

[0037] The present invention also provides the preparation method of graphene-phenolic resin glue described in above-mentioned technical scheme, comprises the following steps:

[0038] The phenolic resin glue, graphene, perchlorethylene resin, cosolvent and accelerator are first mixed to obtain a mixture;

[0039] The mixture, antioxidant, toughening agent, defoamer and wetting agent are mixed for the second time to obtain the graphene-phenolic resin glue.

[0040] In the invention, the phenolic resin glue, graphene, perchlorethylene resin, cosolvent and accelerator are first mixed to obtain a mixture.

[0041] In the present invention, there is no special limitation on the order of the first mixing, and any mixing order can be adopted. In the present invention, the temperature of the first mixing is preferably 50-75°C, more preferably 65-75°C; the time of the first mixing is preferably 30-60min, more preferably 40-50min. In the present invention, the first mixing is carried...

Embodiment 1

[0061] Preparation of graphene-phenolic resin glue:

[0062] Weigh 65 parts by mass of phenolic resin glue with a solid content of 100%, 7 parts of graphene with a particle size of 80nm, 4 parts of perchlorethylene resin, 2 parts of acrylic acid and 0.1 part of triethanolamine, and stir for 30 minutes at 60°C , the rotating speed is 65 rev / min, obtains mixture;

[0063] The obtained mixture, 2 parts of dibutyl hydroxytoluene, 0.5 parts of dibutyl phthalate, 1 part of BYK-054 and 2 parts of Tego650 were stirred for 60 minutes, the speed was 65 rpm, and the temperature was lowered to 40°C. Obtain graphene-phenolic resin glue.

[0064] Preparation of outdoor heavy bamboo flooring:

[0065] Roll the bamboo strips into bamboo bundles, dry and dry the rolled bamboo bundles until the moisture content in the rolled bamboo bundles is ≤5%, and let them stand for 48 hours;

[0066] Adding water to the obtained graphene-phenolic resin glue and adjusting it to a solid content of 20% in ...

Embodiment 2

[0075] Preparation of graphene-phenolic resin glue:

[0076] Take by weighing the phenolic resin glue of 70 parts of solid content 100%, 5 parts, particle diameter is the graphene of 80nm, 5 parts of perchlorethylene resins, 2 parts of propylene glycol methyl ether and 0.2 part of tetramethylthiourea in mass parts, in At 60°C, stir for 45 minutes at a speed of 65 min / rev to obtain a mixture;

[0077] The obtained mixture, 3 parts of tert-butyl hydroquinone, 0.5 parts of triphenyl phosphate, 2 parts of BYK-021 and 2 parts of Tego650 were stirred for 60 minutes at a speed of 65 min / rev, and the temperature was lowered to 40°C to obtain Graphene-phenolic resin glue.

[0078] Preparation of outdoor heavy bamboo flooring:

[0079] Roll the bamboo strips into bamboo bundles, dry and dry the rolled bamboo bundles until the moisture content in the rolled bamboo bundles is ≤5%, and let them stand for 48 hours;

[0080] After adding water to the graphene-phenolic resin glue obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap