High-toughness high-wear-resistance cold work die steel and manufacturing process thereof

A cold work die steel and production process technology, applied in the field of wear-resistant steel, can solve the problems of poor toughness and service life of die steel, and achieve the effect of increasing hardenability, improving structure refinement, and increasing strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

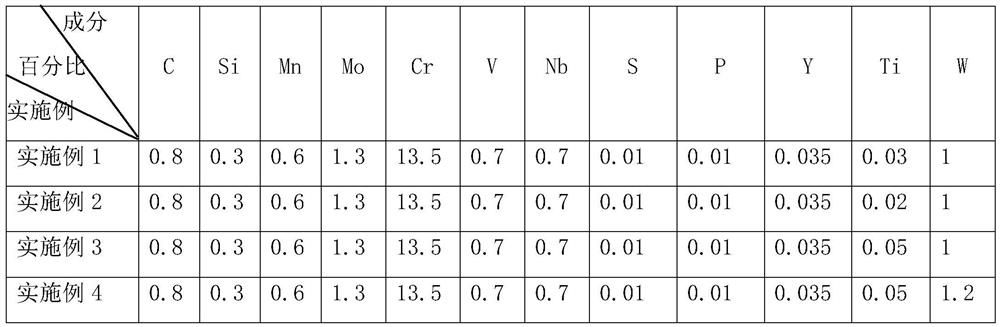

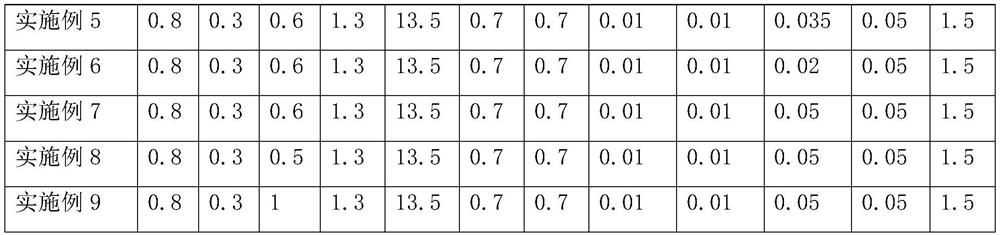

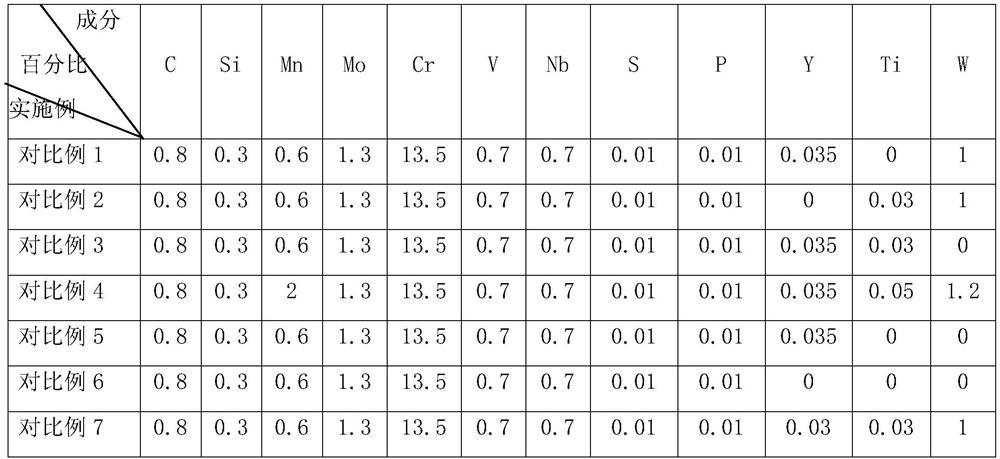

Examples

Embodiment

[0042] A production process of high toughness and high wear resistance cold work die steel, comprising the following steps:

[0043] S1: In terms of mass percentage, it will contain 0.75%-0.9%C, 0.14%-0.20%Si, 0.5%-0.6%Mn, 0.9%-1.1%Mo, 0.4%-0.6%Cr, P≤0.02%, S 100kg steel scrap with ≤0.02% is added to the furnace for smelting, and then low-nitrogen carbon powder, deoxidizer, silicon-manganese, ferrosilicon, high-carbon ferrochrome, titanium, copper, tungsten, vanadium, niobium, and rare earth yttrium are added to the furnace in sequence 1. Aluminum bars for deoxidizer. After all the charge is melted, when the temperature of molten steel is ≥1590℃, use low-pressure deep oxygen blowing method to remove Si and Mn from the flow slag. After fully stirring and sampling and analyzing to meet the requirements, tap out the steel and add it to the ladle Lime, the amount of lime added is 0.25-0.3% of the total amount of converter materials.

[0044] S2: LF refining: transfer the molten s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com