Energy-saving and water-saving printing and dyeing device

A water-saving and treatment box technology, which is applied to the cleaning device for processing textile materials, equipment configuration for processing textile materials, textiles and papermaking, etc. It can solve the problems of pipe wall thickening, affecting the circulation of color paste, waste of color paste, etc. , to achieve the effect of promoting mixing, mixing evenly, and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

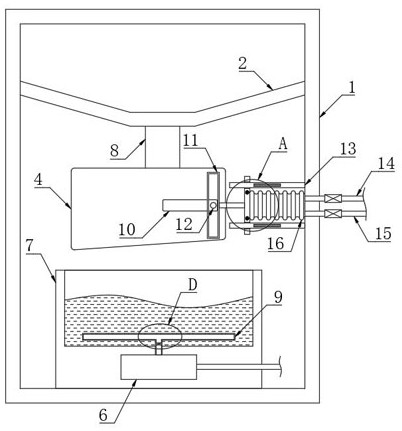

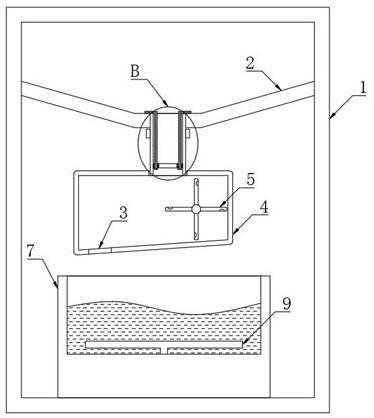

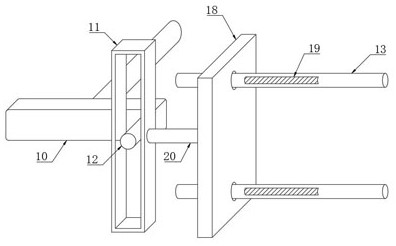

[0032] refer to Figure 1-3 , an energy-saving and water-saving printing and dyeing device, comprising a treatment box 1, further, a pipeline for replenishing color paste can be arranged on the upper wall of the treatment box 1, the inner wall of the treatment box 1 is fixedly connected with a partition 2, and the side wall of the partition 2 A diversion tube 8 is provided throughout, and further, a valve can be arranged on the diversion tube 8 to control the flow of color paste at the upper end of the partition 2, and the side wall of the partition 2 is provided with a slope inclined from both sides to the middle, which is convenient for coloring. Slurry flows into the guide pipe 8, the lower end of the guide pipe 8 is connected with a control box 4, the bottom of the control box 4 is provided with a through hole 3, and the bottom of the processing box 1 is fixedly connected with a printing and dyeing box 7.

[0033] The treatment box 1 is provided with a scraping mechanism f...

Embodiment 2

[0041] refer to Figure 6-7 The difference between this embodiment and Embodiment 1 is that the inner wall of the transition chamber 6 is elastically connected with a piston plate 26 through a compression spring, and the piston plate 26 is in sealing and sliding connection with the inner wall of the transition chamber 6. Further, the left side of the transition chamber 6 needs to be connected with the inner wall of the transition chamber 6 External connection, thereby guaranteeing that piston plate 26 can move left smoothly, the right side wall of piston plate 26 is fixedly connected with rack 24, and the lower end of jet tube 9 extends in the transition chamber 6 and is fixedly connected with gear 25 meshing with rack 24, spraying The trachea 9 is rotatably connected with the bottom of the printing and dyeing box 7 through a rotary joint.

[0042] Compared with Embodiment 1, in this embodiment, after the air enters the transition chamber 6, it will first push the piston plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com