Wafer slide holder and wafer transmission device

A transmission device and a technology of a loading table, which is applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., and can solve problems such as the influence of the wafer transmission process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

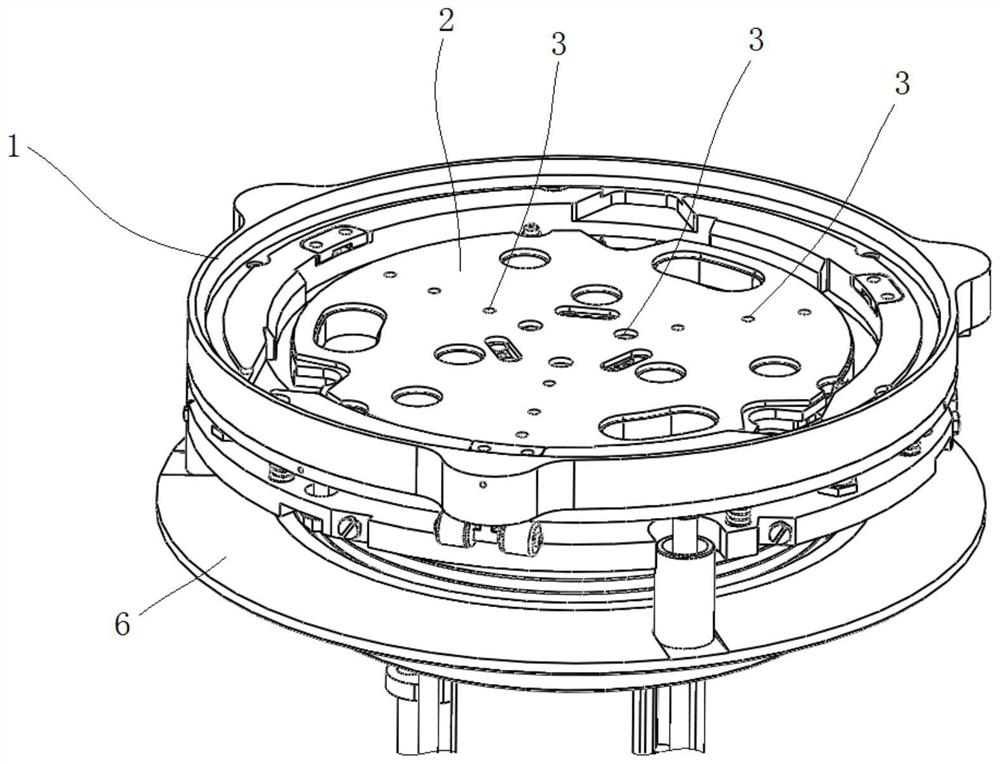

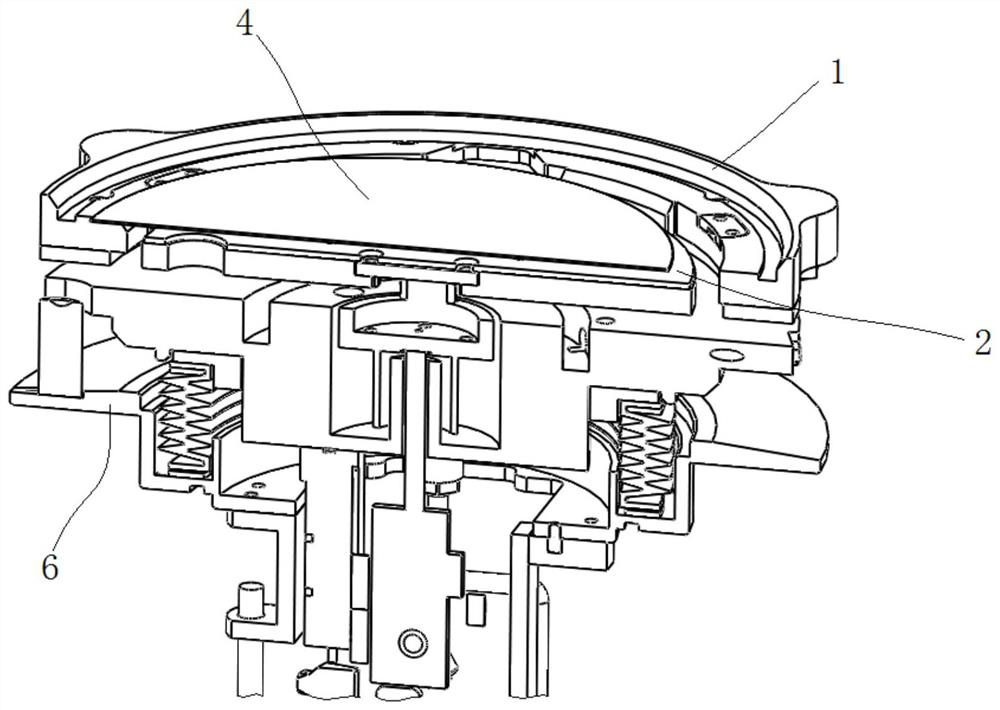

[0035] This embodiment provides a specific implementation of the wafer stage, such as figure 1 with figure 2 As shown, the table body 1 has a groove for accommodating the wafer 4, and a buffer pad 2 is installed at the bottom of the groove, the wafer 4 is placed on the buffer pad 2, and at least one through hole 3 is opened on the buffer pad 2, The through hole 3 is connected with a clean water source or a clean air source. In this embodiment, the through hole 3 is connected with a clean water source. During the transfer process of the wafer 4, the polishing head needs to absorb and take away the wafer 4. When the polishing head absorbs the wafer 4, the clean water source is turned on, and the clean water is discharged from the through hole 3 through the pipeline, and the wafer 4 and the buffer pad 2, so that the wafer 4 is separated from the buffer pad 2, eliminating the water film effect between the wafer 4 and the buffer pad 2, ensuring the stable transmission of the waf...

Embodiment 2

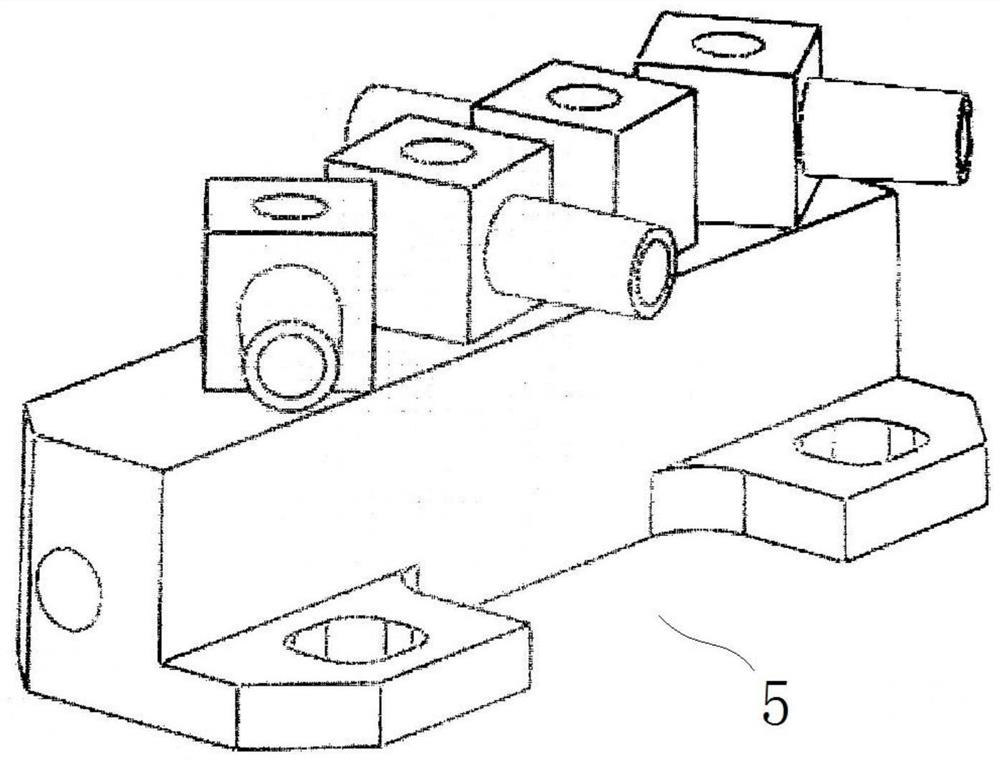

[0043] This embodiment provides a specific implementation of the wafer transfer device, such as figure 1 with figure 2As shown, the wafer transfer device includes a loading and unloading table 6, which has a cavity for accommodating the wafer loading and unloading table 6. A lifting device is installed in the loading and unloading table 6, and the driving end of the lifting device is connected to the wafer loading and unloading table. The bottom of the table body 1 is connected, and the height of the wafer carrier table can be adjusted through the lifting device, so that the position of the wafer 4 is convenient for the polishing head Jinxin to grasp.

[0044] Specifically, the lifting device can use a cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com