Nozzle for turbine, turbomachine turbine equipped with said nozzle and turbomachine equipped with said turbine

一种涡轮机、喷嘴的技术,应用在机器/发动机、机械设备、发动机元件等方向,能够解决密封片脱离、耗时、影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The nozzle according to the invention is referenced 4 and comprises an annular collar 5 on which a plurality of angled nozzle segments 6 are fixed. Nozzle 4 is only partly in Figure 9 is visible in .

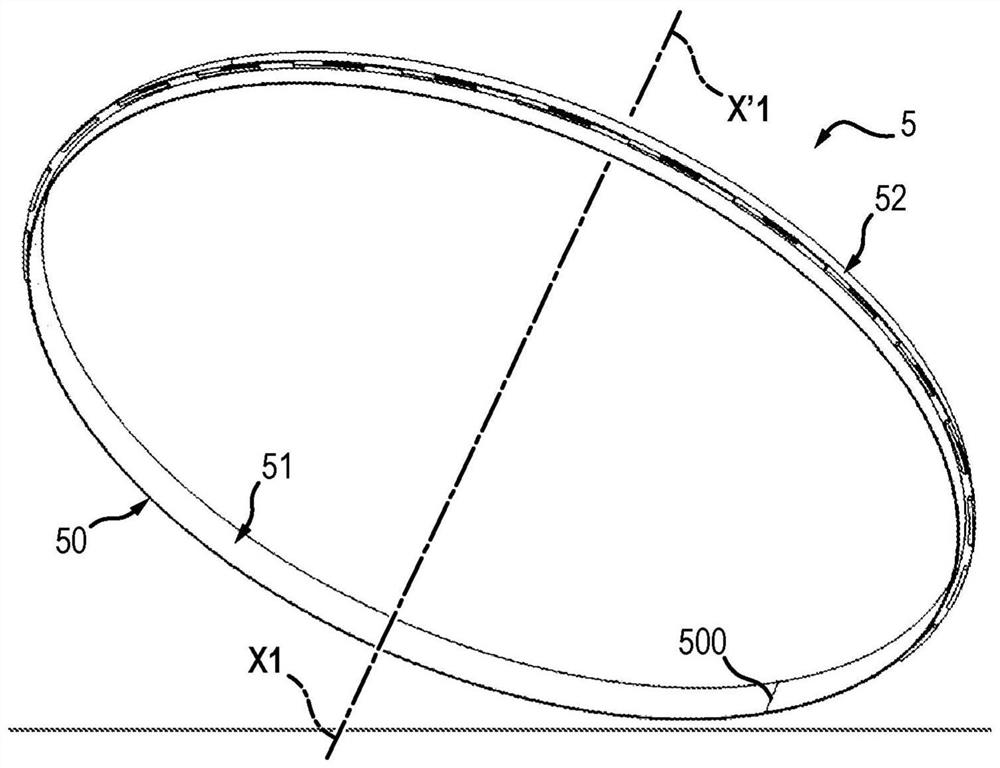

[0043] Now, will combine Figure 2 to Figure 4 The annular collar 5 is described in more detail. The annular collar extends through 360° and has a longitudinal axis X1-X'1.

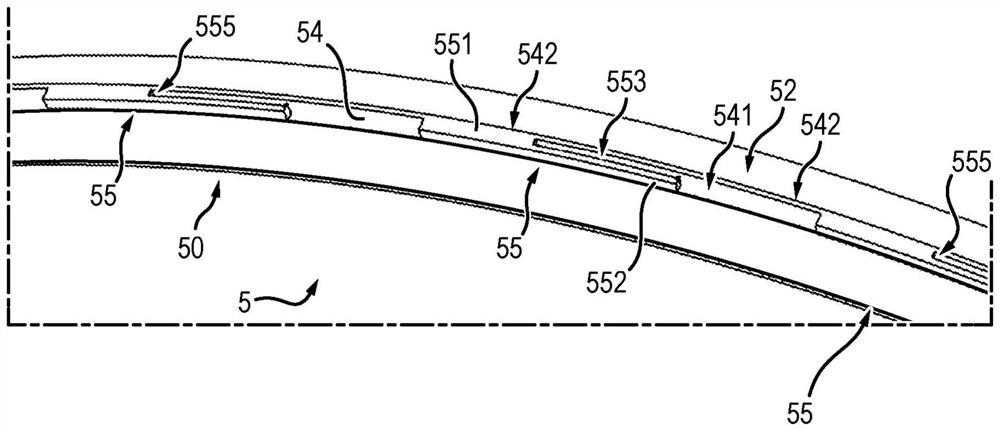

[0044] The annular collar 5 comprises a cylindrical ring portion 50 (or tube) having a minimum width relative to its diameter, a minimum thickness and having a longitudinal axis X1-X′1.

[0045] The ring 50 has a radially inner surface 51 and a radially outer surface 52 .

[0046] as from Figure 7 , Figure 8 and Figure 11Seen more clearly, the inner surface 51 carries a wear resistant material 53 made of one or more elements. Preferably, the wear-resistant material 53 is a honeycomb structure. This abradable material 53 is brazed to the ring 50 and renewed by machining as previously desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com