Spiral dust-settling spraying equipment for green building engineering construction

A technology for engineering construction and green building, which can be applied in the directions of using liquid separating agent, dispersing particle separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Such as Figure 1-7Shown, a kind of green building engineering construction of the present invention uses spiral type dust suppression spraying equipment, comprises:

[0050] The mixing container 1 is provided with a liquid mixing pipe 10 communicating with the mixing container 1 on the outside;

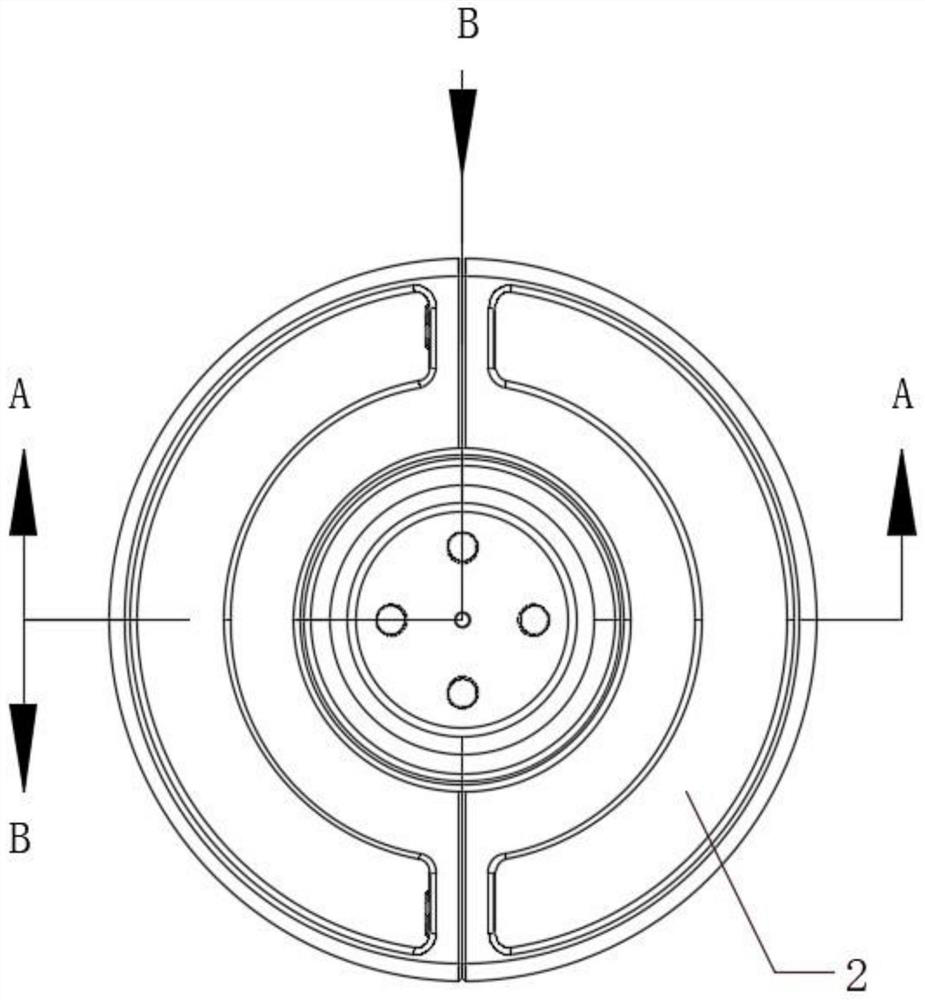

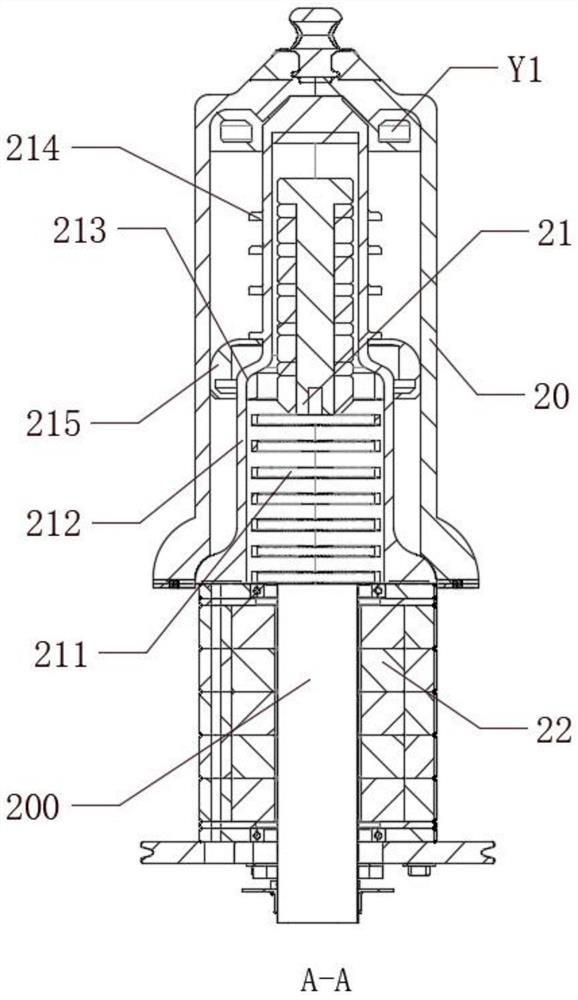

[0051] Jet body 2, jet body 2 is arranged on the outside of mixing container 1 and is flexibly connected with mixing container 1, and the upper end of jet body 2 is connected with fan Z2, wherein, jet body 2 comprises:

[0052] housing 20;

[0053] The liquid-dispensing pipe 200 is arranged in the housing 20 and communicates with the liquid-mixing pipe 10;

[0054] The engaging component 21, the engaging component 21 is arranged in the housing 20;

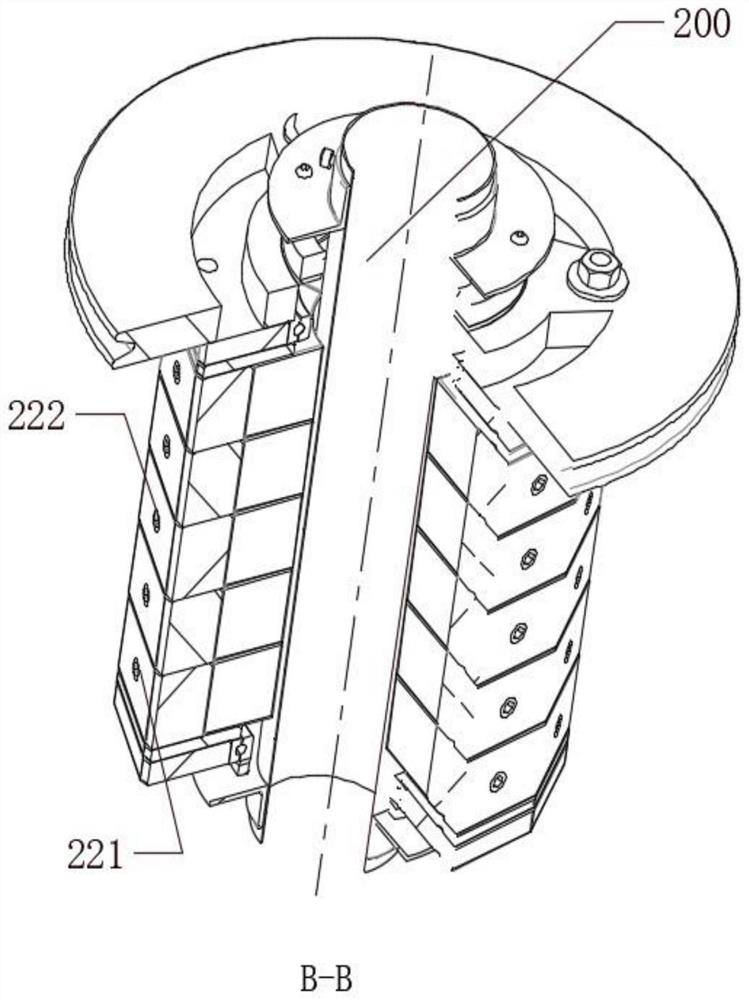

[0055] The spraying slide 22 is sleeved on the inner periphery of the housing 20 and is slidably connected with the shell 20. The tail of the spraying slide 22 is connected with the engaging assembly 21. The outer circumference ...

Embodiment 2

[0062] This embodiment is a further improvement of the previous embodiment, such as Figure 1-7 Shown, a kind of green building engineering construction of the present invention uses spiral type dust suppression spraying equipment, comprises:

[0063] The mixing container 1 is provided with a liquid mixing pipe 10 communicating with the mixing container 1 on the outside;

[0064] Jet body 2, jet body 2 is arranged on the outside of mixing container 1 and is flexibly connected with mixing container 1, and the upper end of jet body 2 is connected with fan Z2, wherein, jet body 2 comprises:

[0065] housing 20;

[0066] The liquid-dispensing pipe 200 is arranged in the housing 20 and communicates with the liquid-mixing pipe 10;

[0067] The engaging component 21, the engaging component 21 is arranged in the housing 20;

[0068] The spraying slide 22 is sleeved on the inner periphery of the housing 20 and is slidably connected with the shell 20. The tail of the spraying slide 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com