Vacuum feeder for polyethylene wax powder

A polyethylene wax powder and feeder technology, which is applied to conveyors, mixers, mixer accessories, etc., can solve the problems of complicated and cumbersome manual feeding operations and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

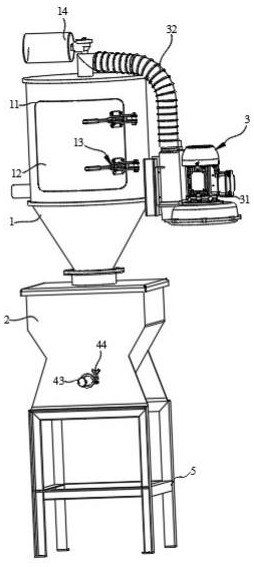

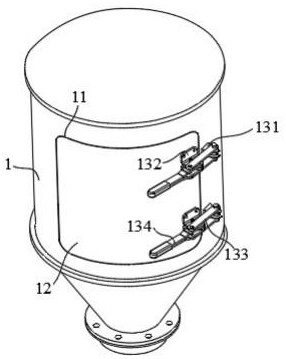

[0030] Such as figure 1 As shown, a vacuum feeder for polyethylene wax powder of the present invention includes: a storage tank 1, a mixing tank 2, a vacuum suction device 3 and a stirring device 4, and the storage tank 1 is fixed on the stirring tank The top of the barrel 2, the storage barrel 1 and the mixing barrel 2 are internally communicated; the vacuum suction device 3 is arranged on one side of the storage barrel 1, and the stirring device 4 is arranged on the mixing barrel 2, wherein the vacuum suction device 3 can negatively press the stirring device 4 and evenly feed the material. The present invention is simple in structure and easy to operate. The automatic discharge of raw materials is realized through the vacuum suction device 3, and the sufficient mixing and mixing of materials is realized through the stirring device 4. At the same time, the automatic feeding of materials can be carried out under the state of continuous stirring and mixing. , There is no mater...

Embodiment 2

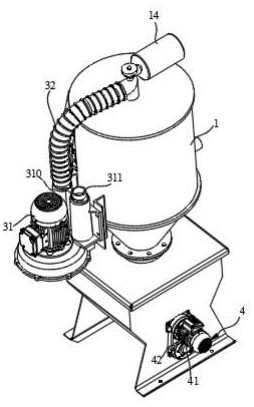

[0032] Such as figure 1 and figure 2 As shown, a vacuum feeder for polyethylene wax powder of the present invention includes: a storage tank 1, a mixing tank 2, a vacuum suction device 3 and a stirring device 4, and the storage tank 1 is fixed on the stirring tank The top of the barrel 2, the storage barrel 1 and the mixing barrel 2 are internally communicated; the vacuum suction device 3 is arranged on one side of the storage barrel 1, and the stirring device 4 is arranged on the mixing barrel 2, wherein the vacuum suction device 3 can negatively press the stirring device 4 and evenly feed the material. The present invention is simple in structure and easy to operate. The automatic discharge of raw materials is realized through the vacuum suction device 3, and the sufficient mixing and mixing of materials is realized through the stirring device 4. At the same time, the automatic feeding of materials can be carried out under the state of continuous stirring and mixing. , Th...

Embodiment 3

[0035] Such as figure 1 As shown, a vacuum feeder for polyethylene wax powder of the present invention includes: a storage tank 1, a mixing tank 2, a vacuum suction device 3 and a stirring device 4, and the storage tank 1 is fixed on the stirring tank The top of the barrel 2, the storage barrel 1 and the mixing barrel 2 are internally communicated; the vacuum suction device 3 is arranged on one side of the storage barrel 1, and the stirring device 4 is arranged on the mixing barrel 2, wherein the vacuum suction device 3 can negatively press the stirring device 4 and evenly feed the material. The present invention is simple in structure and easy to operate. The automatic discharge of raw materials is realized through the vacuum suction device 3, and the sufficient mixing and mixing of materials is realized through the stirring device 4. At the same time, the automatic feeding of materials can be carried out under the state of continuous stirring and mixing. , There is no mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com