Full-process atomization cleaning and disinfection device for gynecological nursing

An atomization cleaning and disinfection device technology, applied in the field of medical equipment, can solve problems such as incomplete disinfection, external environmental pollution, and operator injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

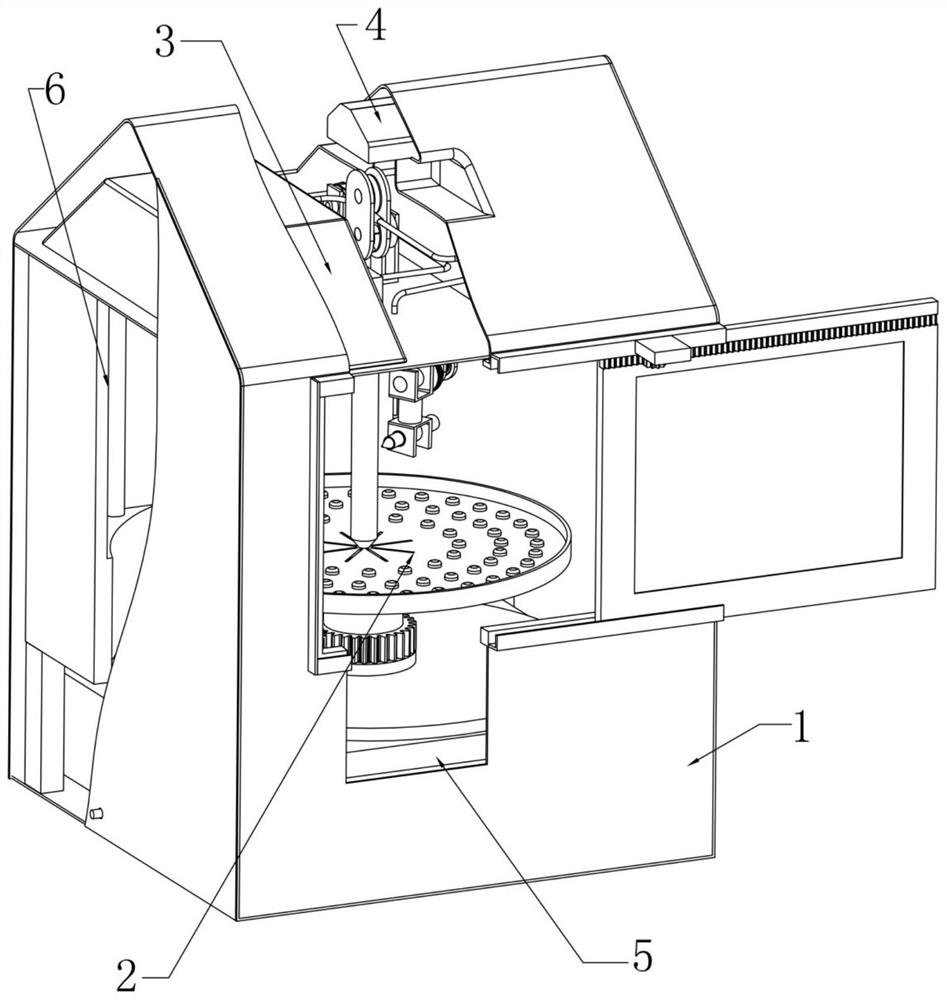

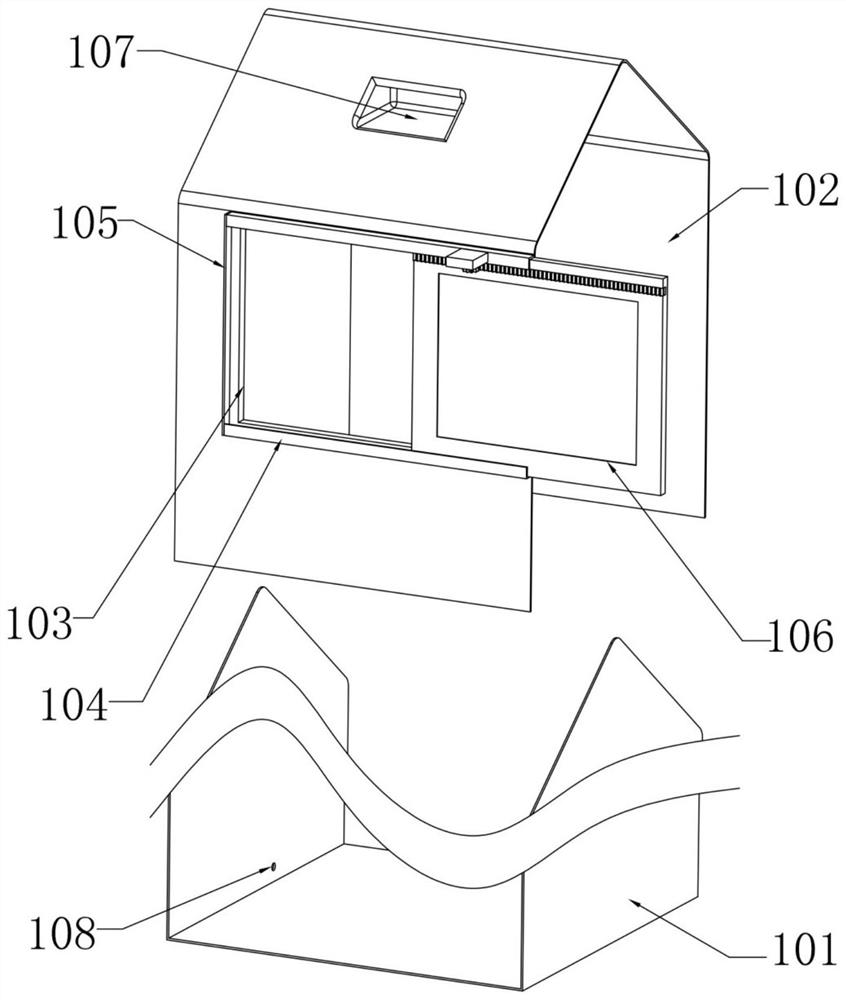

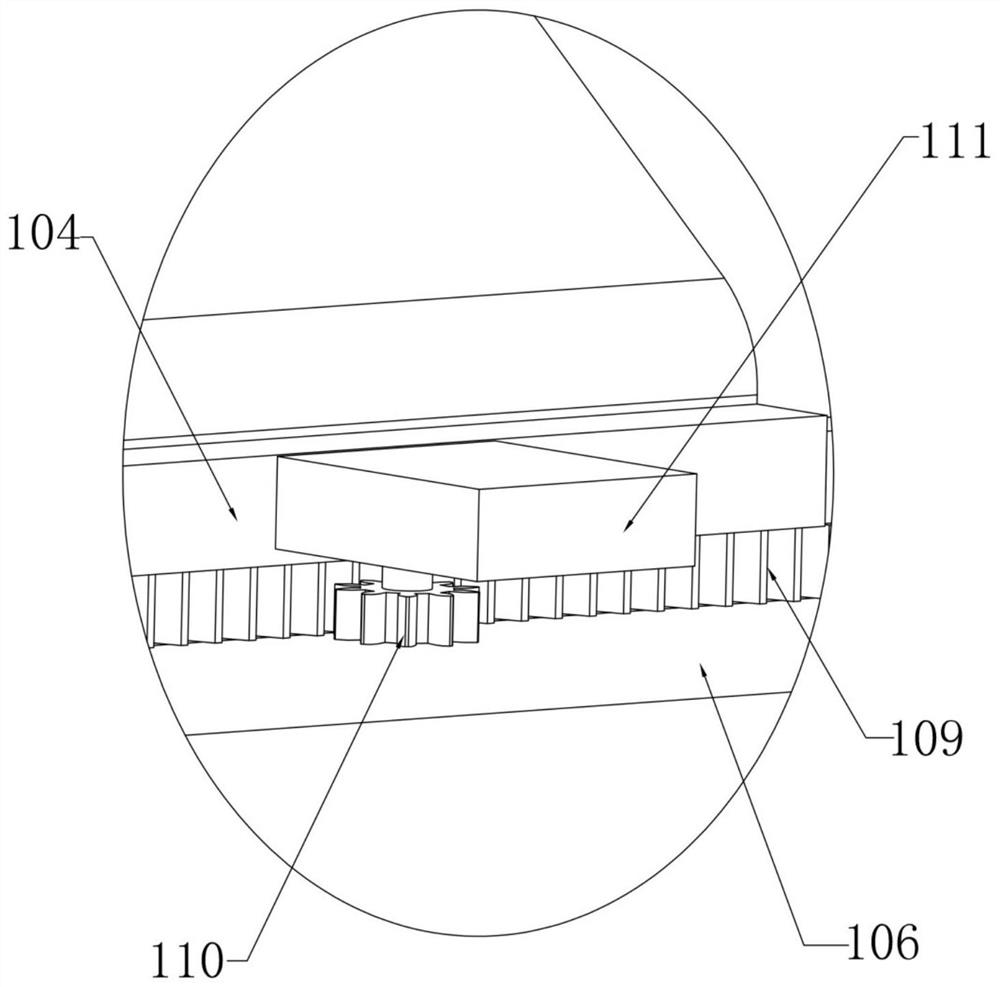

[0049] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 A full-process atomization cleaning and disinfection device for gynecological care is shown, the lower housing 101 in the installation housing assembly 1 is a fixed installation base, the lower housing 101 is a U-shaped sheet metal structure, and the workpiece is placed in the assembly 2 Four sets of outriggers 202 are fixedly installed on the upper plane bottom of the lower housing 101. A tray base 201 is fixedly installed on the outriggers 202. A lower tray 205 is arranged above the tray base 201. The distilled water cleaning assembly 3 is connected to the top plate. 301 is fixedly installed on the upper part of the lower housing 101, the distilled water tank 302 is fixedly installed on the upper plane side of the connecting top plate 301, the flushing head 30704 communicates with the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com