On-line surfacing device and method for cone roller of ring rolling machine

A ring rolling machine and tapered roller technology, which is applied to the on-line surfacing device of the ring rolling machine and the on-line surfacing of the ring rolling machine's tapered roller, which can solve the problems of increased repair time and long time consumption of the tapered roller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

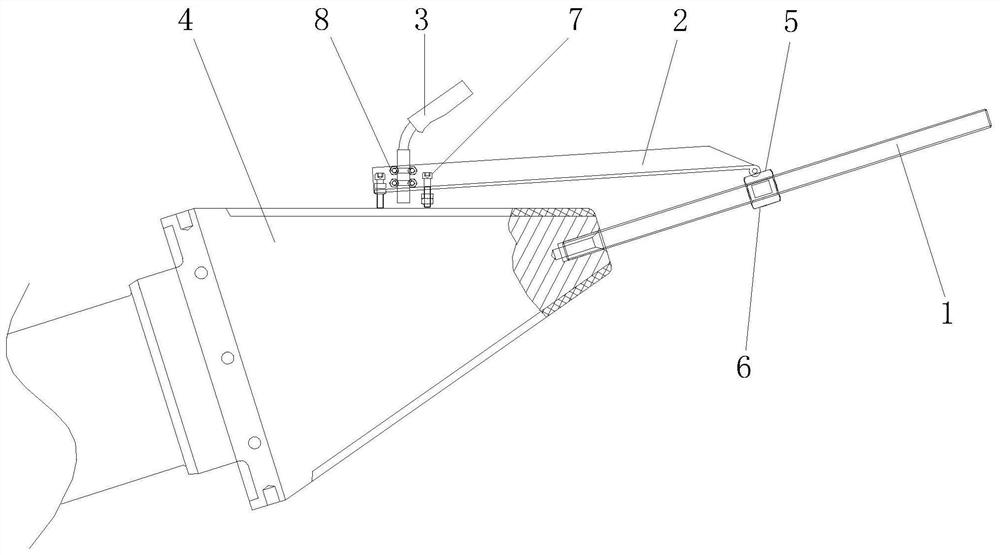

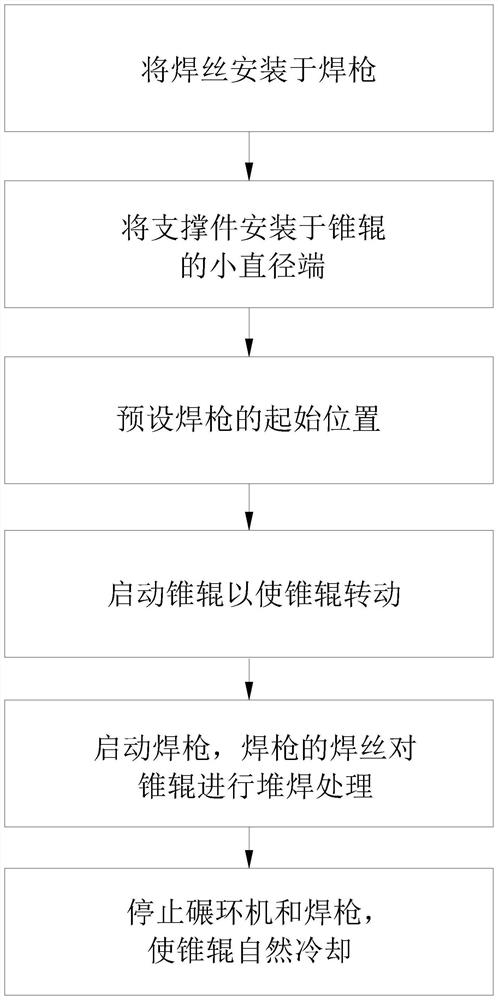

[0034] Please refer to figure 1 , in order to solve the above problems, the present invention proposes an on-line surfacing device for tapered rollers of a ring rolling machine, including a support 1, a connecting piece 2 and a welding torch 3; the support 1 is installed on the small diameter end of the tapered roller 4 and The tapered rollers 4 rotate synchronously, one end of the connecting piece 2 is installed on the supporting piece 1 and moves linearly along the supporting piece 1 under the rotation drive of the supporting piece 1, and the other end of the connecting piece 2 extends to The to-be-surfacing position of the tapered roller 4 , the welding torch 3 is installed on the end of the connecting member 2 away from the support member 1 and its nozzle faces the to-be-surfacing position of the conical roller 4 . Install the support member 1 on the tapered roller 4 and rotate synchronously with the tapered roller 4, drive the connecting member 2 to move linearly along th...

Embodiment 2

[0038] Please refer to figure 1 , the support member 1 is connected to the center of the small-diameter end, and the support member 1 is arranged along the axial direction of the tapered roller 4 . The tapered roller online surfacing device of the ring rolling machine also includes a nut 5; the support 1 is a screw; the nut 5 is connected to the support 1 and can move linearly along the rod of the support 1; The end of the connector 2 away from the welding torch 3 is connected to the nut 5 . The tapered roller online surfacing device of the ring rolling machine also includes a limit rod 6; the end of the limit rod 6 is connected to the nut 5, and the limit rod 6 is erected on the frame of the ring rolling machine to The rotation of the connecting piece 2 and the welding torch 3 is restricted. Wherein, the nut 5 is a thickened nut, which can improve the connection stability, and further can improve the stability and uniformity of the surfacing.

Embodiment 3

[0040] Please refer to figure 1 , the on-line surfacing device for the tapered roller of the ring rolling machine also includes a distance screw 7; The outer wall of the tapered roller contacts, and the end of the connecting piece 2 away from the welding torch 3 is hinged to the nut 5 . By adjusting the protruding length of the distance screw 7 on the connecting piece 2, the nozzle of the welding torch 3 does not come into contact with the outer wall of the tapered roller 4 all the time, so as to ensure that the welding torch 3 can work normally And the surfacing effect of the welding torch 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com