Double-station laser cutting workstation

A laser cutting and workstation technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as hidden safety hazards, inadequate protection, and lack of auxiliary tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

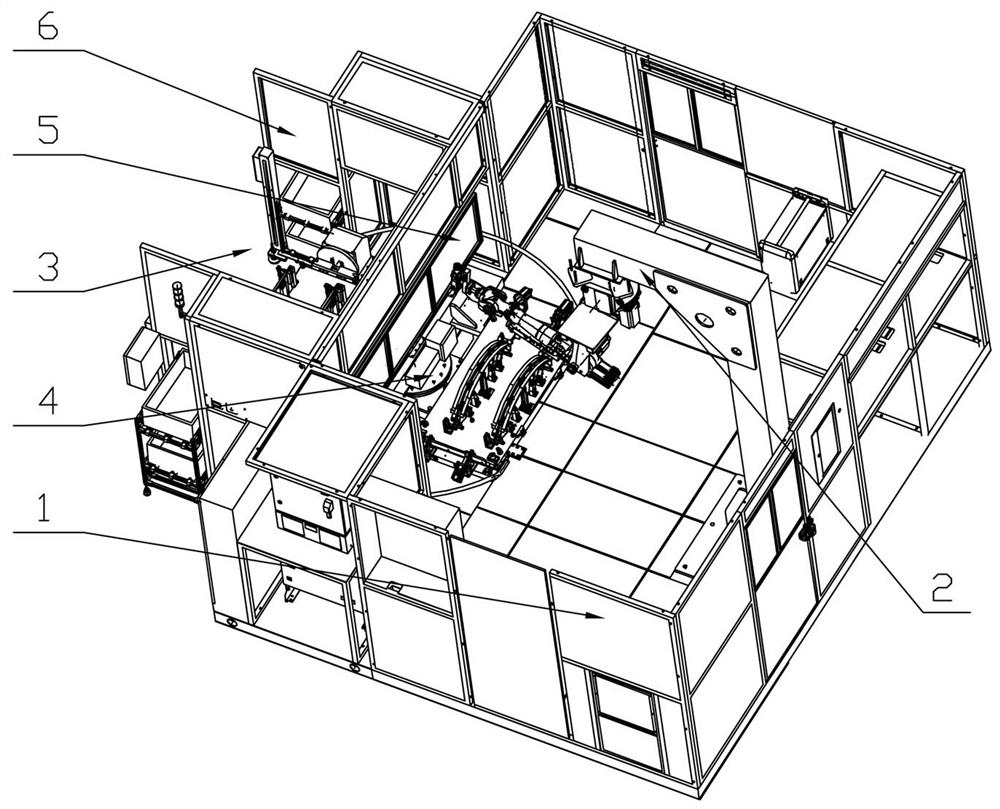

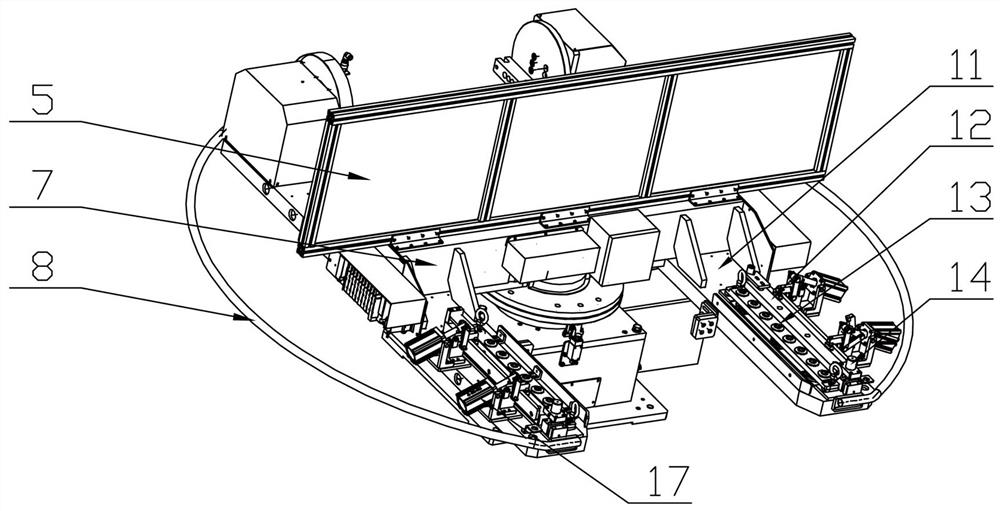

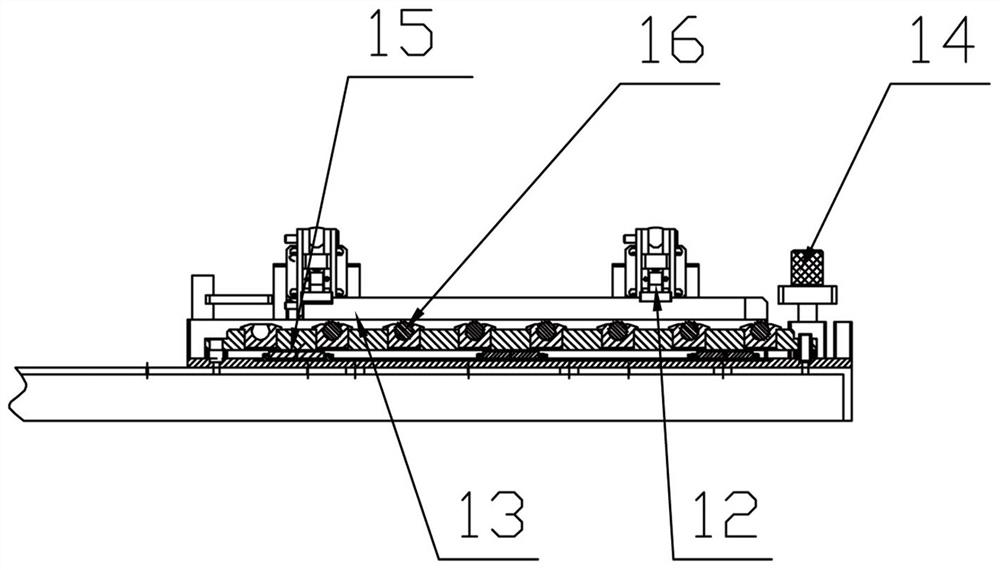

[0017] Such as figure 1 As shown, a double-station laser cutting workstation is provided with a protective cover 1 on the periphery of the space of the laser workstation, and a laser cutting robot 2 is arranged in the protective cover 1; a material inlet 3 is provided on the protective cover 1; 1 is equipped with a circular turntable 4, the bottom of the circular turntable 4 is connected to the rotary drive device, and the forward rotation and inversion of the turntable 4 are controlled through the control system of the control cabinet, and the limit switch is set to realize the stop function in place; The upper surface of the turntable 4 is provided with a crossbeam 7 along the diameter direction, and a vertical shading plate 5 is arranged on the crossbeam 7, and the shading plate 5 is located at the material inlet 3, and forms an integral protective room with the protective cover 1; There is a clamping tool, the clamping tool on one side of the beam 7 is located in the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com