Grinding wheel dressing method capable of automatically adjusting discharge voltage

A technology of discharge voltage and automatic adjustment, which is used in grinding machine parts, abrasive surface adjustment devices, metal processing equipment, etc., can solve problems such as the speed not meeting the established requirements, the reduction of conductivity, and the reduction of the conductivity of grinding wheels and molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

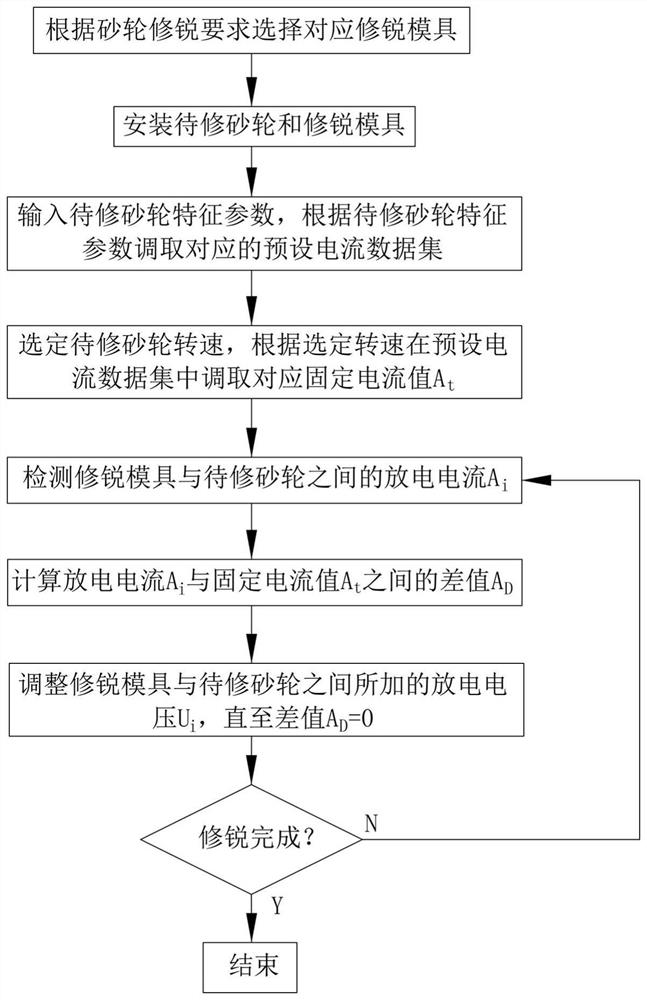

[0023] Such as figure 1 As shown, a grinding wheel sharpening method for automatically adjusting the discharge voltage includes the following steps:

[0024] S1. Select the corresponding sharpening mold according to the sharpening requirements of the grinding wheel, install the grinding wheel to be repaired and the sharpening mold; the grinding wheel to be repaired is the anode, and the sharpening mold is the cathode;

[0025] S2. Input the characteristic parameters of the grinding wheel to be repaired, and retrieve the corresponding preset current data set according to the characteristic parameters of the grinding wheel to be repaired;

[0026] S3. Select the speed of the grinding wheel to be repaired, and call the corresponding fixed current value A in the preset current data set according to the selected speed t ;

[0027] S4, electrified grinding, closed-loop control of the discharge voltage between the grinding wheel to be repaired and the sharpening mold, so that the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com