Large vestibule spanning type installation method

An installation method and leap-forward technology, which can be used in transportation and packaging, conveyors, cranes, etc., and can solve problems such as difficulty in hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

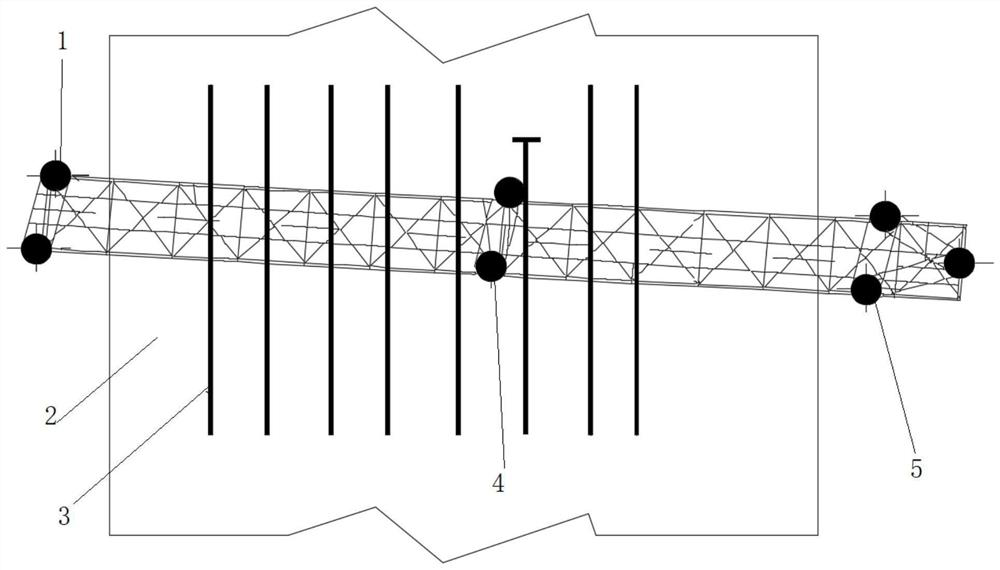

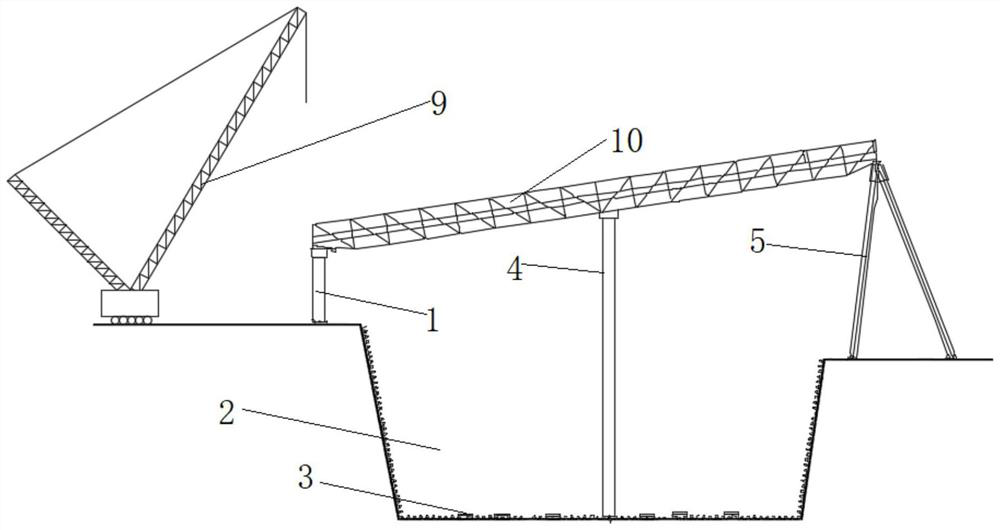

[0023] Such as figure 1 with image 3 As shown, in this embodiment, when installing a large-scale corridor, a certain section of the large-scale corridor needs to cross a special section—the trench 2 with an elevation of -9.50m, and there are 7 tracks 3 in the trench 2, so the trench 2 Limited space occupancy. In order to complete the spanning construction, hoist each truss section in turn, hoist the 10 large-span truss sections spanning the special section occupied by the restricted site, and hoist the remaining truss sections as a whole. The hoisting of the 10 large-span truss sections includes the following steps:

[0024] S1. Preparation stage:

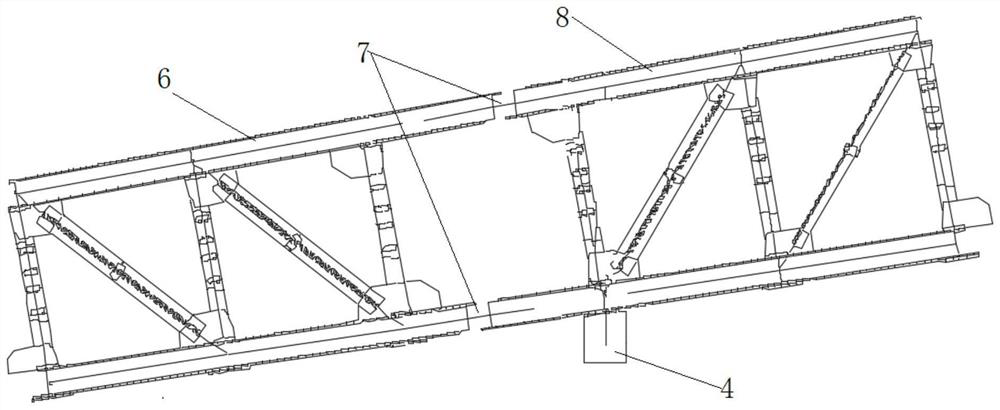

[0025] With the high end as the front and the low end as the rear, the rear of the midpoint of the large-span truss section 10 is divided into two front and rear trusses (8, 6). The front truss 6 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com