Infiltration device for glass fiber drawing

A glass fiber and infiltration device technology, applied in the field of glass fiber manufacturing, can solve the problems of poor squeegee effect, difficult infiltration, and reduced glass fiber performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

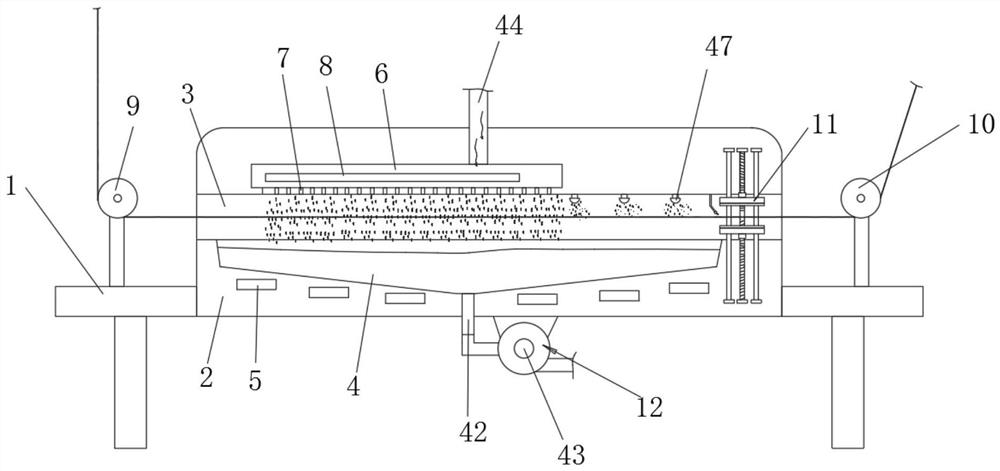

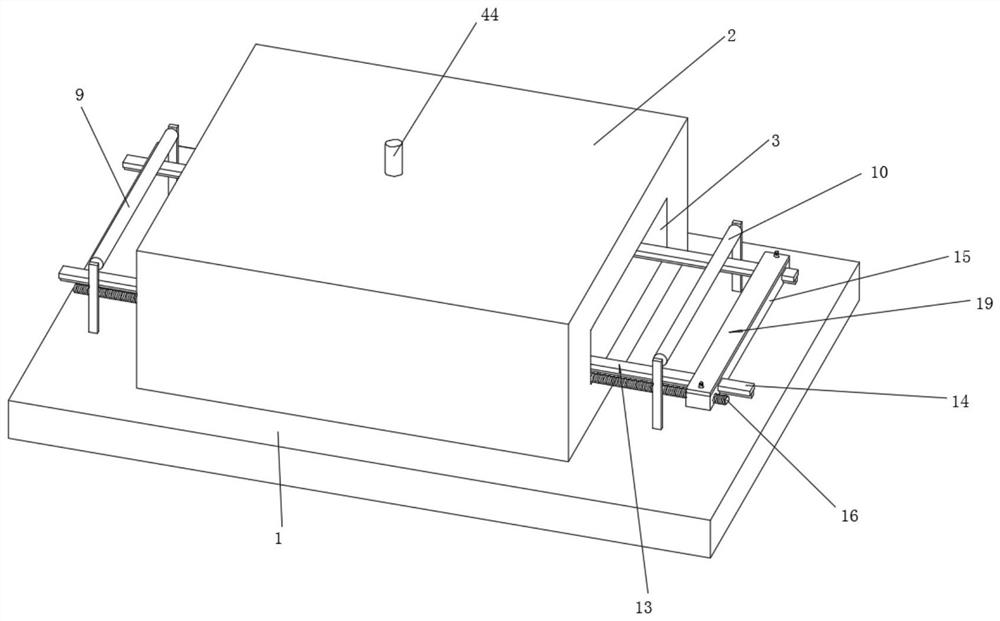

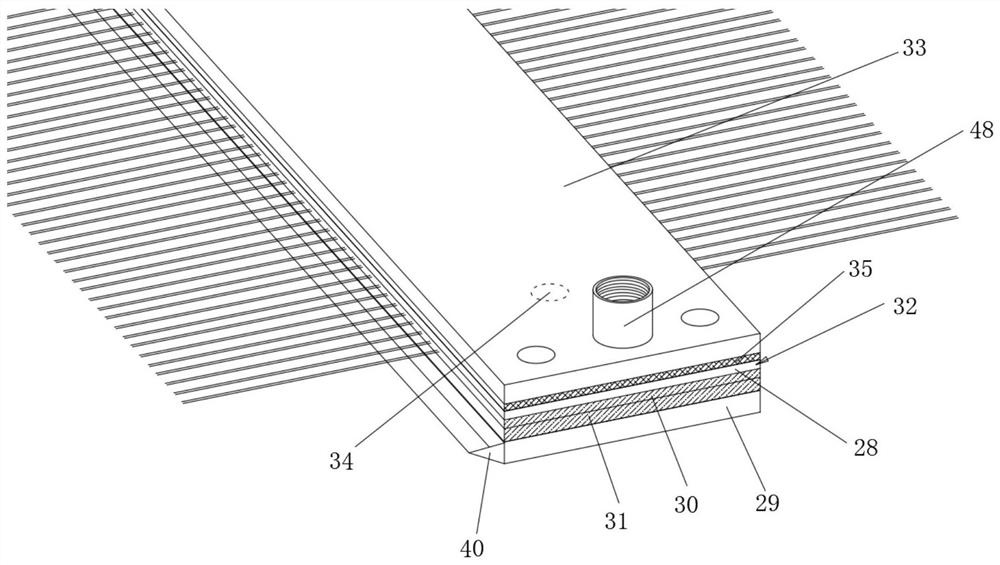

[0029] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, an infiltration device for glass fiber drawing in the present invention includes a workbench 1, on which a wetting box 2 is provided, and an infiltration channel 3 for glass fibers to pass through is provided in the infiltration box 2. The bottom of the infiltration channel 3 is provided with a glue storage pool 4, the side wall of the glue storage pool 4 is provided with a first electric heater 5, and the infiltration box 2 is provided with a glue spraying pool 6 above the infiltration channel 3 , the bottom of the glue pouring pool 6 is provided with a glue spraying through hole 7, the first electric heater 8 is arranged in the glue spraying pool 6, and the workbench 1 is respectively provided with a second electric heater 8 on both sides of the infiltration channel 3. A line roller 9 and a second line roller 10, the infiltration box 2 is provided with a scraping mechanism 11 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com