A kind of biuret crystalline hydrate and its preparation method and application

A technology of crystalline hydrate and biuret, applied in the field of biuret crystalline hydrate and preparation thereof, can solve problems such as difficulty in preparing biuret hydrate, and achieve the effects of being easy to obtain, cheap and obtainable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Weigh 2g of commercially available biuret powder into 20mL of water, stir for 10min to disperse the powder, then transfer the dispersion to the polytetrafluoroethylene lining of the hydrothermal kettle and seal the hydrothermal kettle, then Put it in an oven to react at 100°C for 12h.

[0039] Step 2: After the reaction is finished, after natural cooling, the obtained product is washed by centrifugation and vacuum-dried at 40° C. for 12 hours, and the obtained powder is a biuret crystalline hydrate with a novel structure.

Embodiment 2

[0041] Step 1: Weigh 2g of commercially available biuret powder into 20mL of water, stir for 10min to disperse the powder, then transfer the dispersion to the polytetrafluoroethylene lining of the hydrothermal kettle and seal the hydrothermal kettle, then Put it in an oven to react at 110°C for 12h.

[0042] Step 2: After the reaction is finished, after natural cooling, the obtained product is washed by centrifugation and vacuum-dried at 40° C. for 12 hours, and the obtained powder is a biuret crystalline hydrate with a novel structure.

Embodiment 3

[0044] Step 1: Weigh 2g of commercially available biuret powder into 20mL of water, stir for 10min to disperse the powder, then transfer the dispersion to the polytetrafluoroethylene lining of the hydrothermal kettle and seal the hydrothermal kettle, then Put it in an oven to react at 120°C for 12h.

[0045] Step 2: After the reaction is finished, after natural cooling, the obtained product is washed by centrifugation and vacuum-dried at 40° C. for 12 hours, and the obtained powder is a biuret crystalline hydrate with a novel structure.

[0046] In Examples 1-3, commercially available biuret powders were subjected to hydrothermal treatment at different temperatures and dried to obtain biuret crystalline hydrates with novel structures.

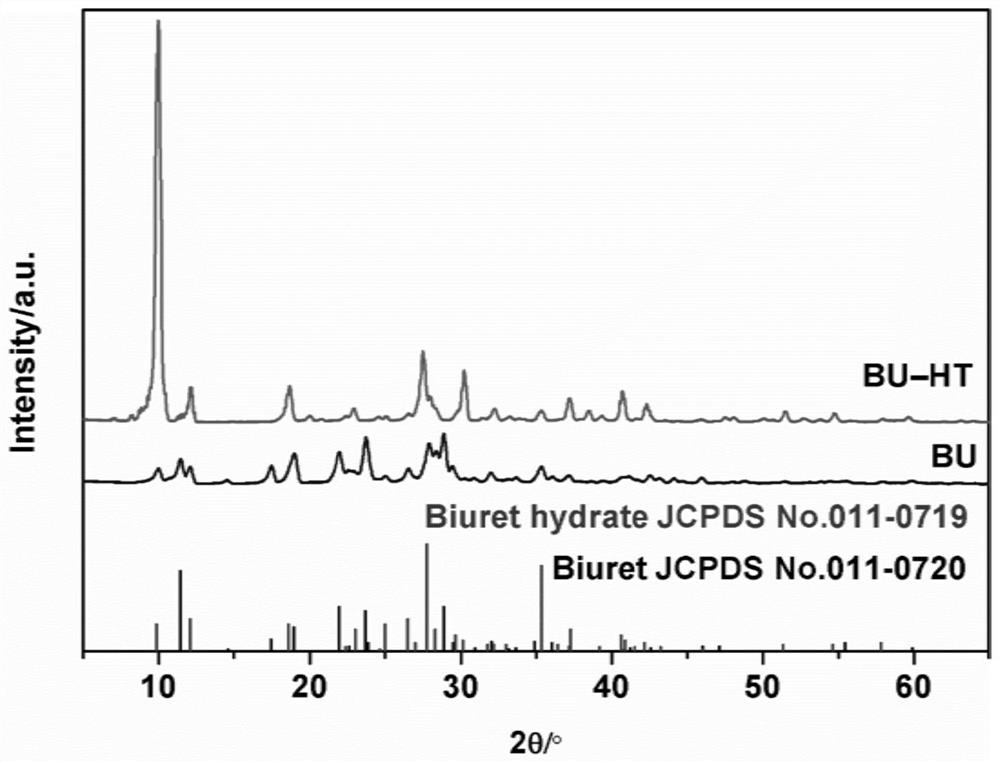

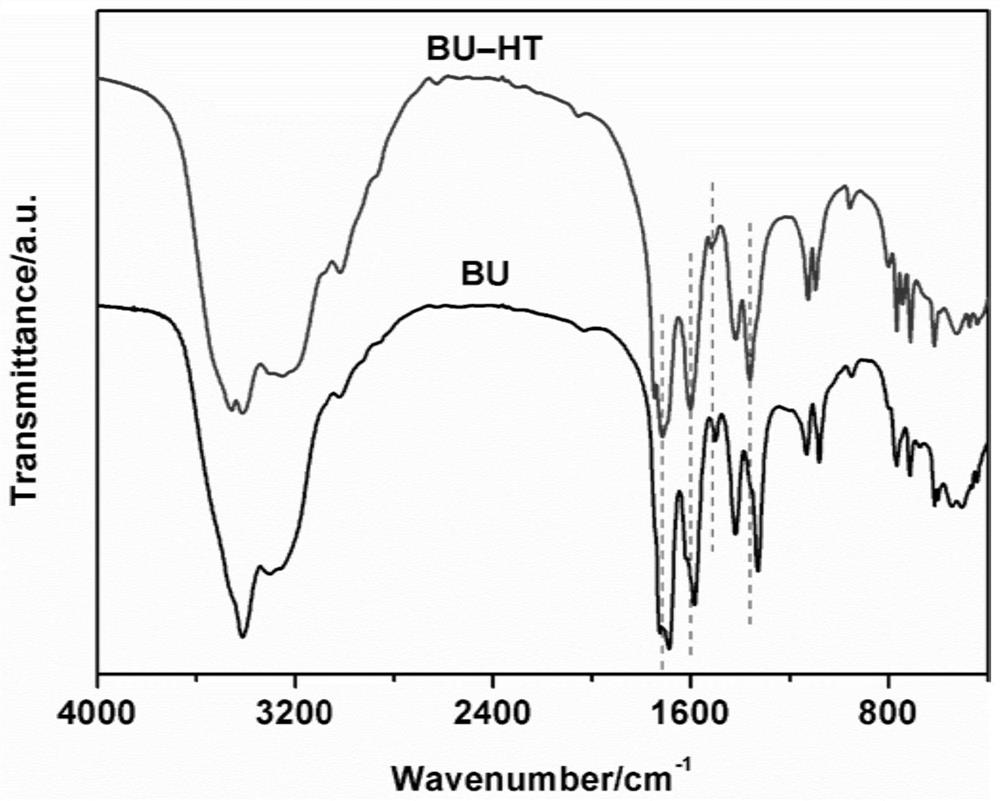

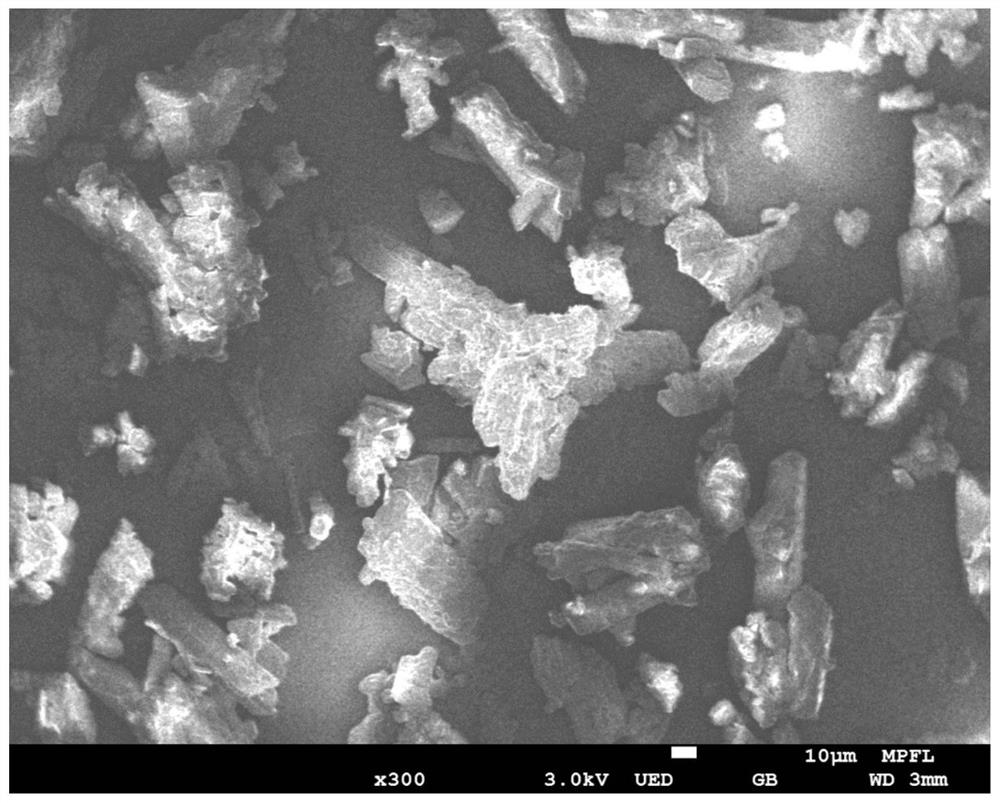

[0047] figure 1 It is the X-ray diffraction (XRD) pattern of the biuret hydrate obtained by the commercially available biuret and hydrothermal treatment in Examples 1 to 3. It can be seen that the commercially available biuret contains biuret ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com