Stainless steel wire annealing device and annealing method thereof

A wire annealing and stainless steel technology, which is applied in the direction of heat treatment process control, furnace, furnace type, etc., can solve the problems of uneven wire quality, waste of ammonia gas accumulation, easy oxidation and discoloration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

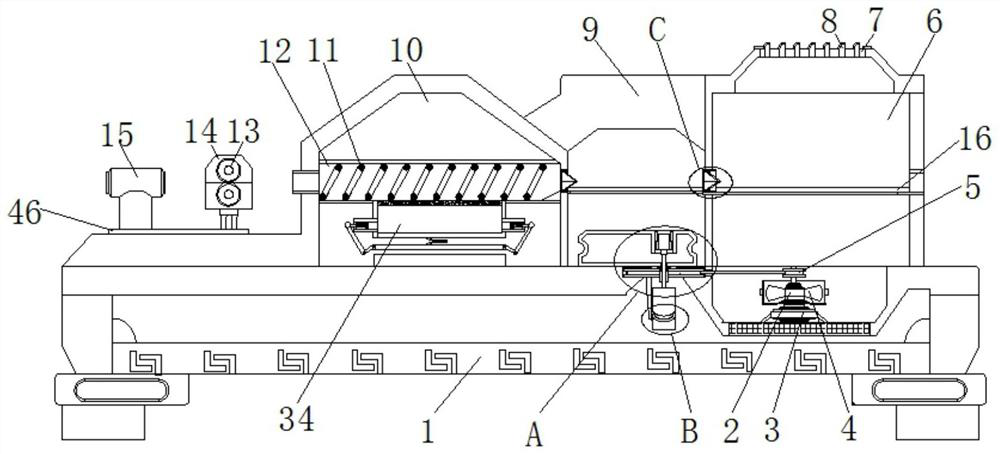

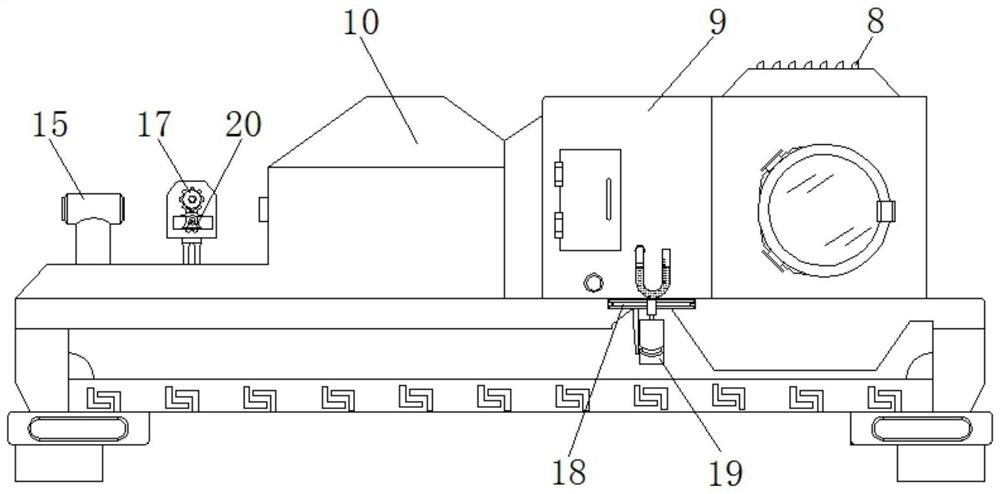

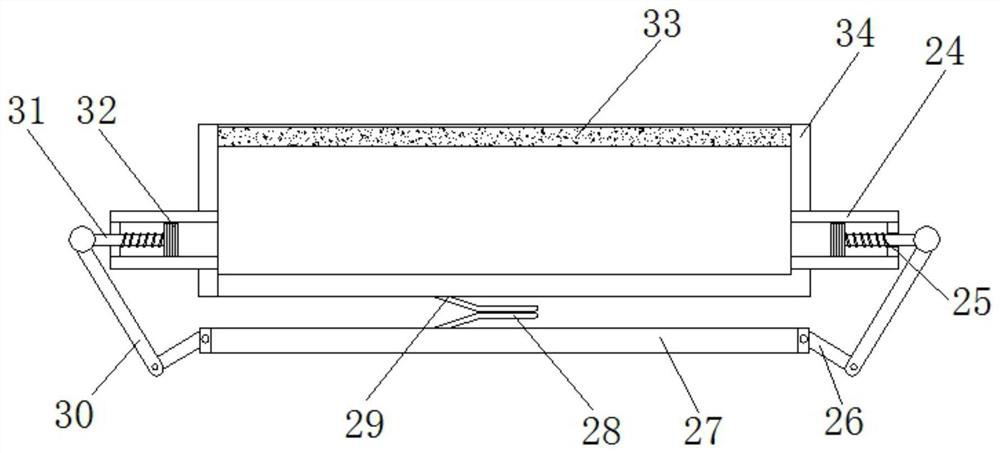

[0042] Example 1, such as Figure 1-3 As shown, when the stainless steel wire is annealed, the stainless steel wire is first passed through the inside of the wire barrel 15, and the stainless steel wire is placed between the two sets of transmission wheels 13, and then the stainless wire is passed into the inside of the heating tube 11, One end of the stainless steel wire rod is placed on the top of the wire placement plate 16, then the power is turned on to start the drive motor B20, and the drive motor B20 drives the gear 17 and the transmission wheel 13 to rotate. direction, and then drive the two sets of mounting plates B14 to rotate in the opposite direction, so that the stainless steel wire is slowly transported inside the mounting tube A12, and then the heating tube 11 heats the stainless steel wire, and then the heat conduction plate 33 will heat the heating tube 11. Heat is introduced into the interior of the installation chamber 34. When the temperature rises to a sp...

Embodiment 2

[0043] Example 2, such as Figure 1-3 As shown, when the stainless steel wire rod is transported into the inside of the reaction chamber 9, the drive motor A3 is first started, and the drive motor A3 drives the drum 2 and the fan blade 4 to rotate, and then the drum 2 drives the pulley A5 to rotate, and the pulley B18 is on the belt 40 Under the action of the belt pulley A5, it will drive the installation pipe B44 to rotate. The installation pipe B44 will drive the connecting rod C42 and the guide cylinder 19 to rotate through the cooperation of the chute A43 and the slider B41. The guide cylinder 19 is in the ring guide groove 23 and Under the cooperation of the guide rod 36, the reciprocating straight line moves up and down, thereby driving the connecting rod C42 and the anti-skid block 37 to move up and down reciprocally. Because the density of ammonia gas is less than the density of air, when the chute B48 breaks away from the slide block A38, the ammonia gas is released fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com