Active noise reduction and sound insulation large-hollow-rate wallboard and preparation method thereof

A technology of active noise reduction and hollow rate, applied in the direction of sound insulation, sound generating equipment, building components, etc., can solve the problems of no active noise reduction function, inconvenient installation and disassembly, poor sound insulation and noise reduction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

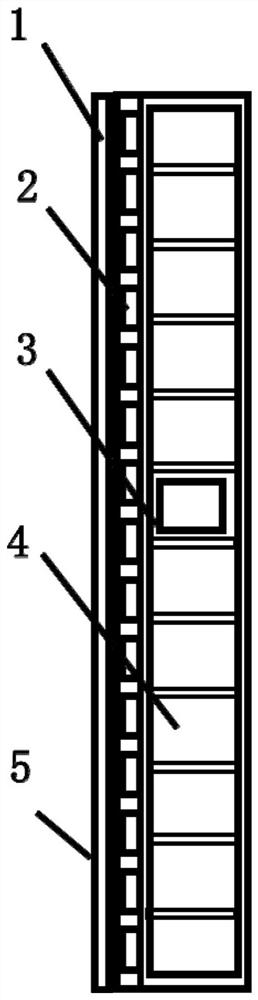

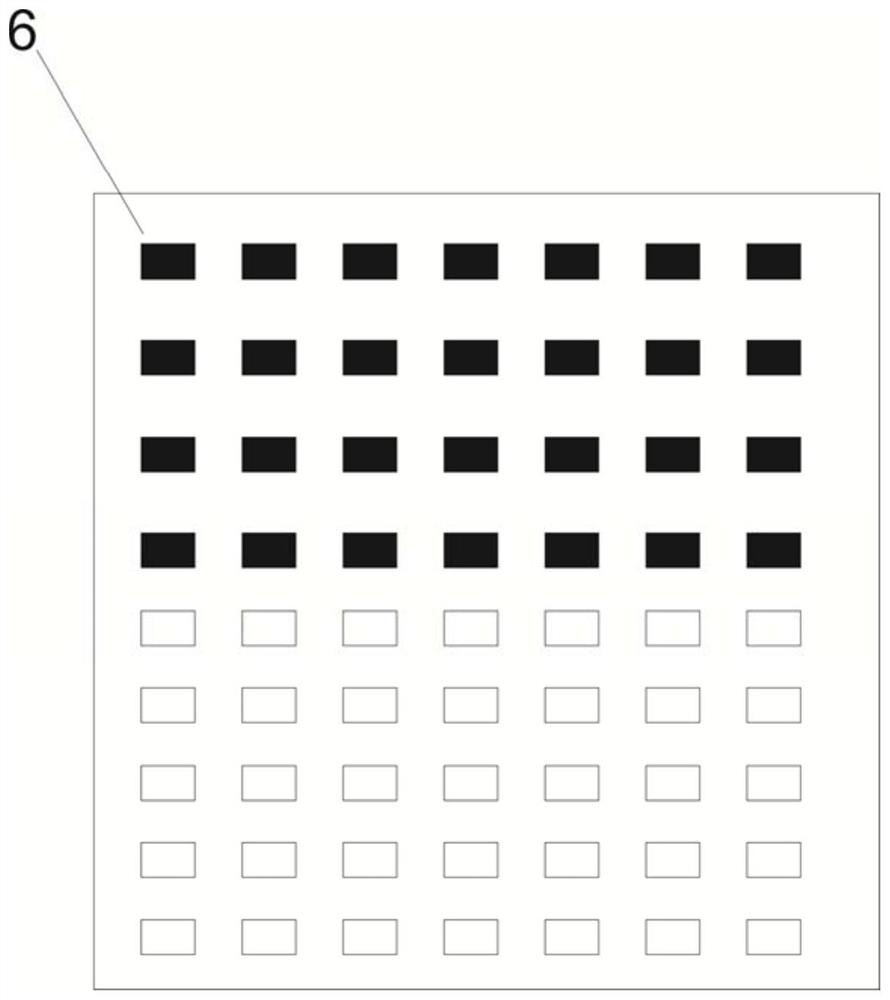

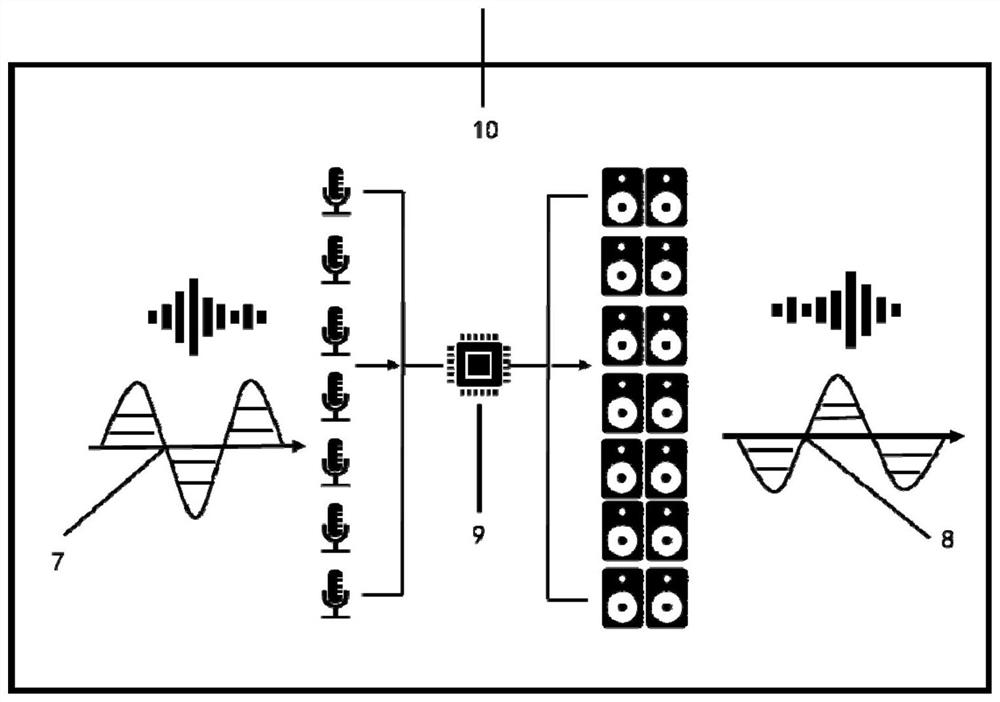

[0044] This example provides an active noise reduction and sound insulation large hollow wall panel, such as Figure 1-2As shown, it includes a wallboard main body 4 and an active noise reduction structure 2. The active noise reduction structure 2 includes a battery, a radio device, an acoustic processor 3, and a sounding device. The wallboard main body 4 is made by extrusion molding of fiber-reinforced cement-based composite materials , the hollow rate of the main body of the wallboard is 50-70%, the compressive strength of the main body of the wallboard 4 is 10-20MPa, the battery is located outside the main body of the wallboard 4, the battery is specifically a solar battery 1, and a decorative layer is arranged on the outside of the solar battery 1, The decorative layer is light-transmitting plexiglass. The radio device, the acoustic processor and the sound generating device are located inside the main body of the wall panel. The battery, the radio device, the acoustic proce...

Embodiment 2

[0051] This example provides an active noise-cancelling sound-insulating large hollow rate wall panel. The only difference from Example 1 is that the size of the microphone is 200×300×100mm, the size of the speaker is 15×20×4mm, and the rest of the steps and parameters are the same .

Embodiment 3

[0053] This example provides an active noise-cancelling sound-insulating large hollow rate wall panel. The only difference from Example 1 is that the size of the microphone is 100×300×100mm, the size of the speaker is 15×25×4mm, and the rest of the steps and parameters are the same .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com