Time sequence actuating mechanism

An actuating mechanism and timing technology, which is applied in the direction of manual mechanism, combustion engine, wing fan control mechanism, etc., can solve the problems of low reliability and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

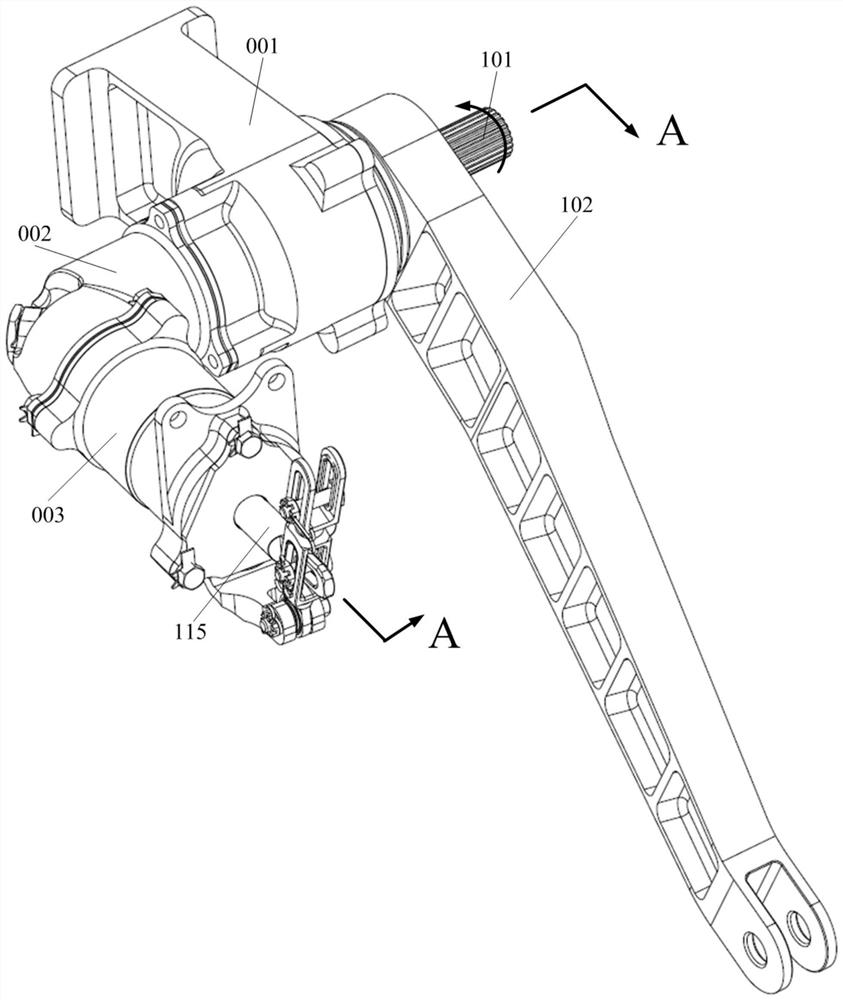

[0026] The present invention proposes a technical solution for a timing acting mechanism. Its basic composition figure 1 with figure 2 As shown, the timing mechanism is made of an input housing, an intermediate housing, an output housing, an input shaft, a rocker arm, a torque beaker, a spiral spiral, a steel ball, a ball, and a spiral mark. The sleeve, the input cone gear, the output cone gear, the limit sleeve, the pin, the secondary spiral bond sleeve, the secondary spiral spiral sleeve, the steel ball and the output shaft composition.

[0027] The input shaft 101 and the first spiral bond sleeve 107 are connected by a spline, and the rocker arm 102 and the sawtooth sleeve 103 are solidified. The spiral spline sleeve 104 and the first spiral spline sleeve 107 by the spiral spiral bond 107 Connection, there is two steel balls 105 between the end surface of the secondary spiral sleeve 104 and the track disk 106, one of the steel ball 105 located on the left surface of the helix s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com