Air cycle machine

A technology of air cycle machine and protruding ring, which is applied in the direction of air handling equipment, mechanical equipment, aircraft parts, etc., and can solve the problems of low sealing and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

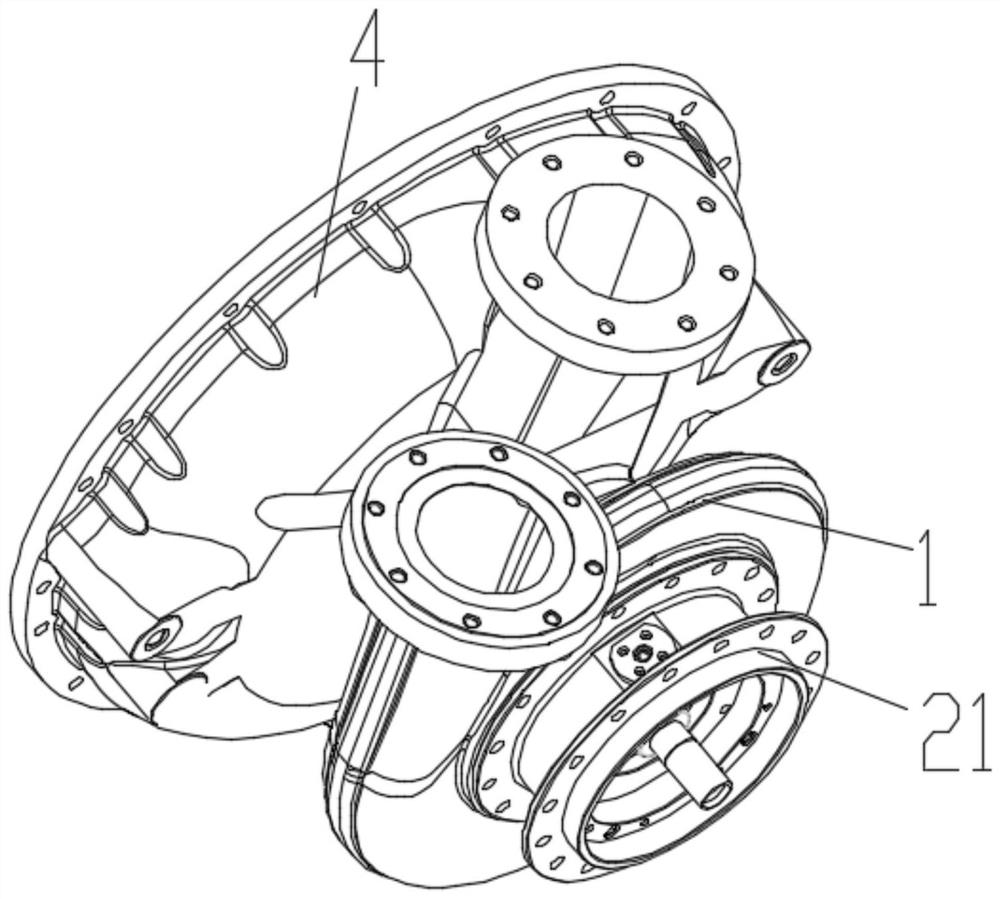

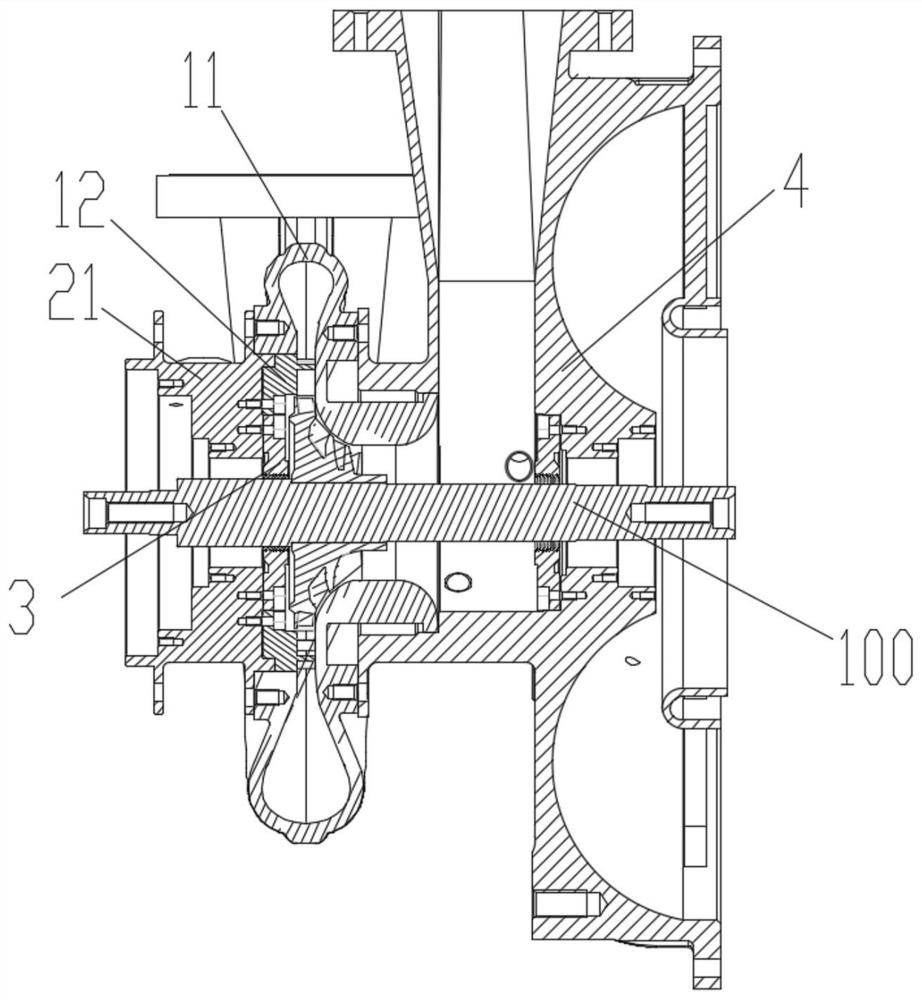

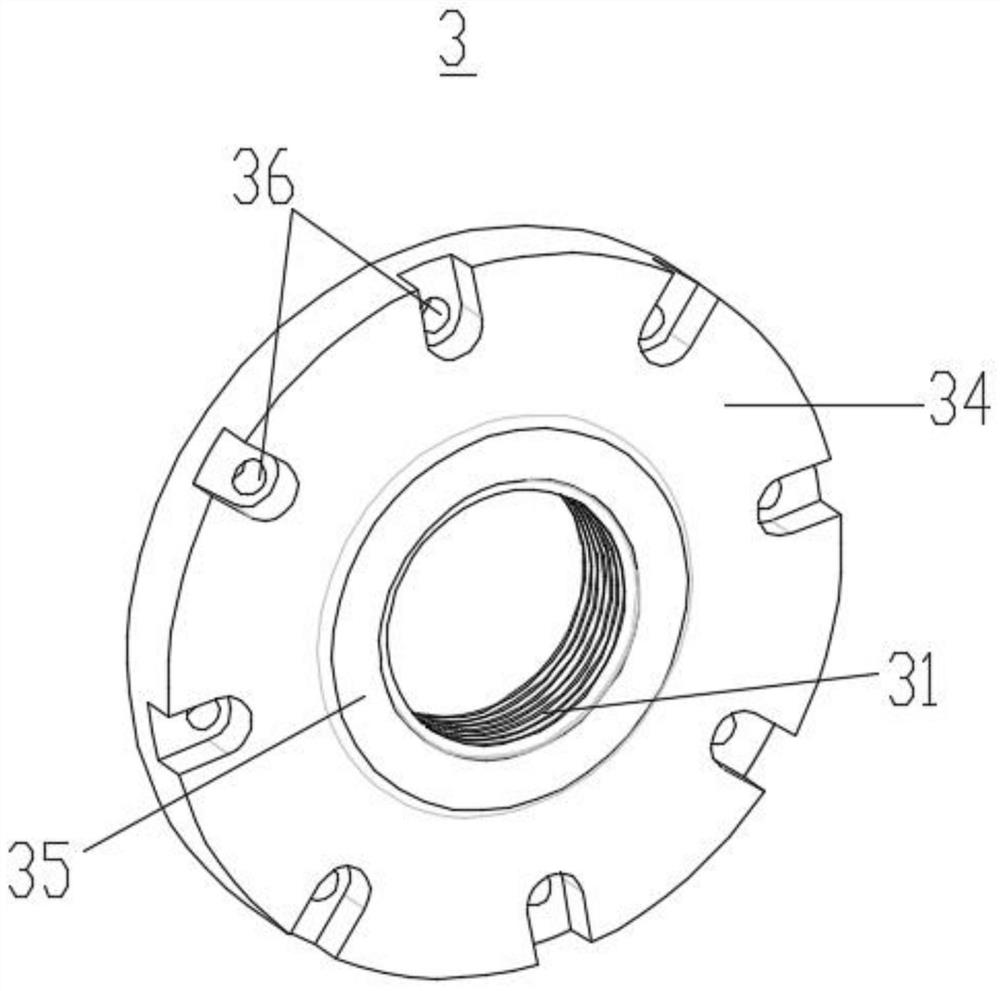

[0024] Combine Figures 1 to 7 , According to the embodiment of the present invention, there is provided an air cycle machine comprising a compressor 1, a turbine (not shown), the fan 4, the compressor 1 and the turbine, the turbine shaft common 4 100, further comprising a bearing housing assembly, said bearing assembly includes a bearing housing seat 21, the bearing block and the first axial side of the bearing housing 21 of the compressor 21 set on the outer peripheral side of the rotating shaft 100 1 the volute 11 is connected to the compressor, the axial bearing housing 21 is connected to a second side of the turbine volute of the turbine, the axial bearing seat 21 on the first side further has a seal member 3, it can be appreciated said first axial side to the one side of the volute 11 of the compressor 21 towards the bearing housing, and said second axial side of the bearing block 21 was toward the side of the turbine volute to 21 connected to the bearing housing through both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com