Method for forming film layer with uniform thickness distribution and semiconductor structure

A technology of thickness distribution and film layer, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve problems such as uneven film thickness, breakdown, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The method for forming a film with uniform thickness distribution and the specific implementation of the semiconductor structure provided by the present invention will be described in detail below with reference to the accompanying drawings.

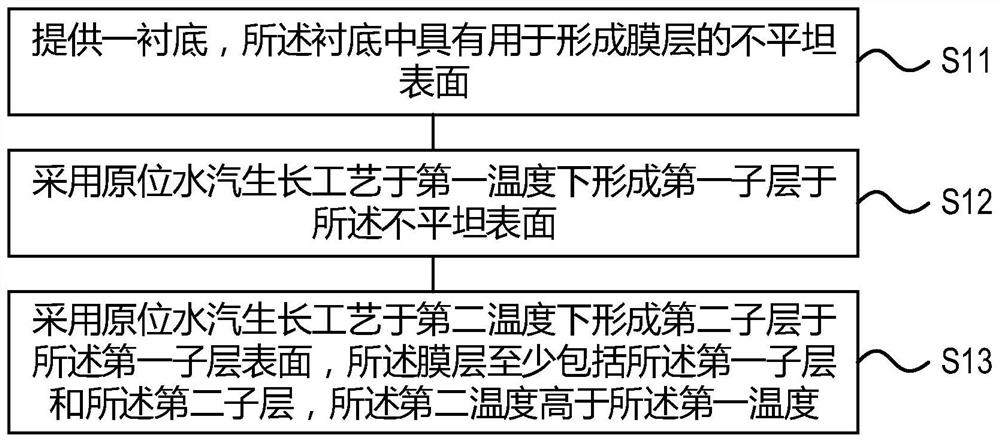

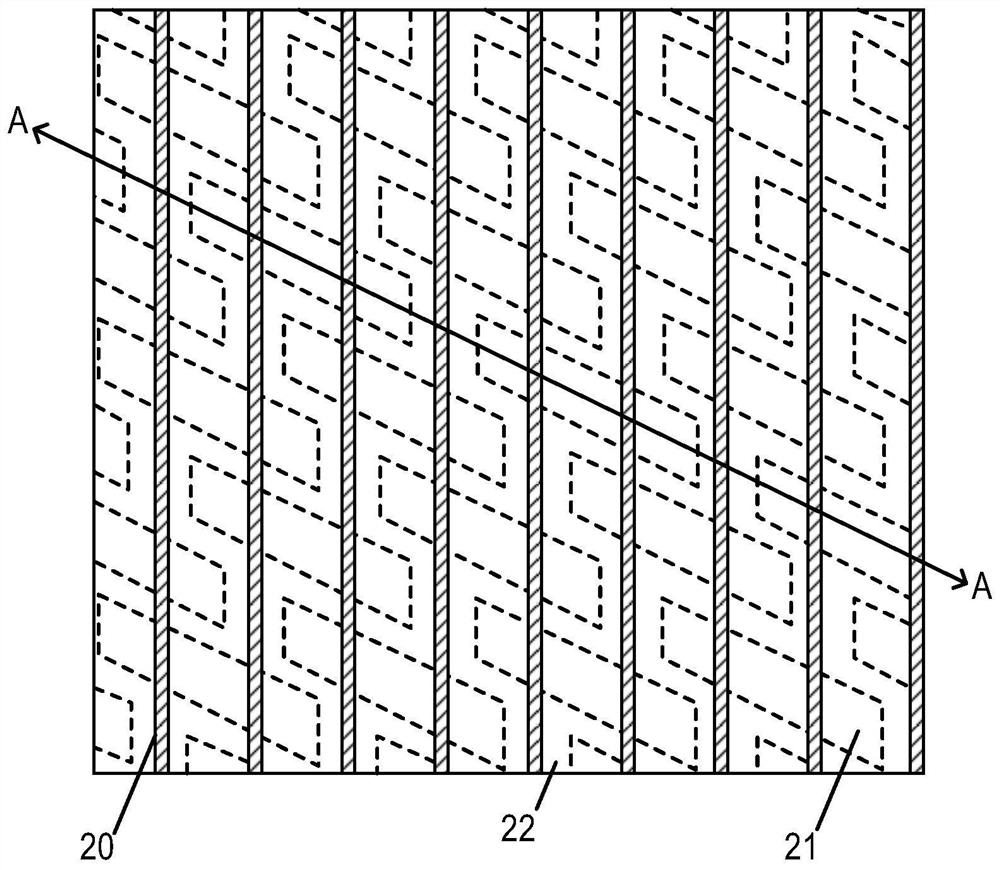

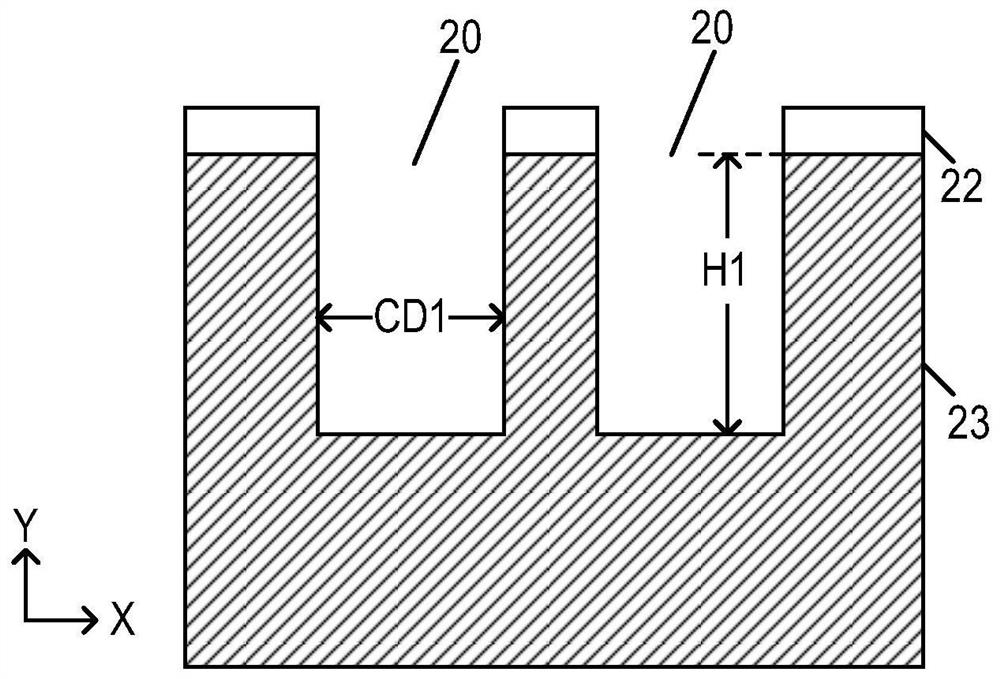

[0034] This specific embodiment provides a method for forming a film layer with uniform thickness distribution, with figure 1 It is a flow chart of a film layer forming method with uniform thickness distribution in the specific embodiment of the present invention, with Figures 2A-2F It is a schematic cross-sectional view of the main process in the process of forming a film layer with uniform thickness distribution in the specific embodiment of the present invention. like figure 1 , Figures 2A-2F As shown, the method for forming a film layer with uniform thickness distribution provided by this specific embodiment includes the following steps:

[0035] In step S11, a substrate 23 is provided, and the substrate 23 has an uneven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com