Preparation of low-temperature fraction capable of improving strength and application of low-temperature fraction in heated cigarettes

A low-temperature, distillate technology, applied in the field of heating cigarettes, can solve the problems of easy loss of volatile components, rough and dry feeling, and large amount of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

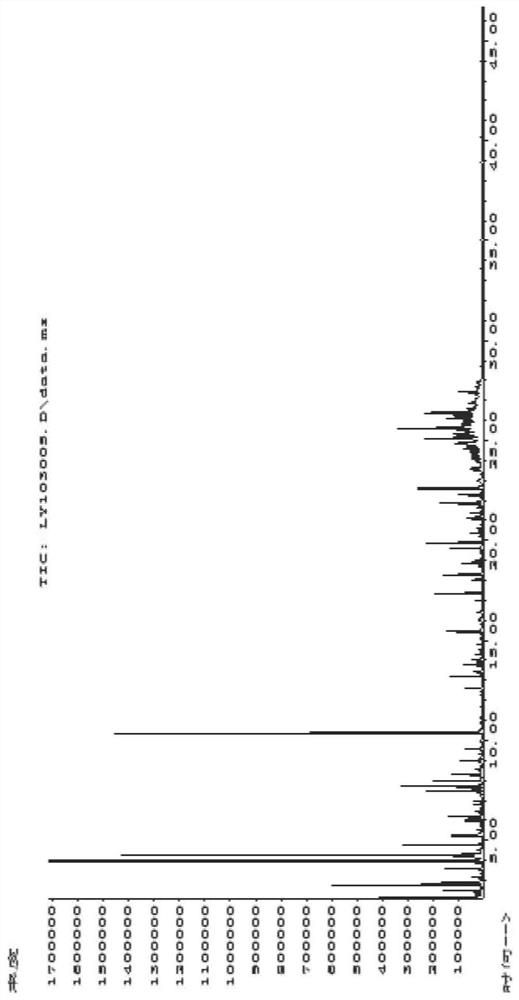

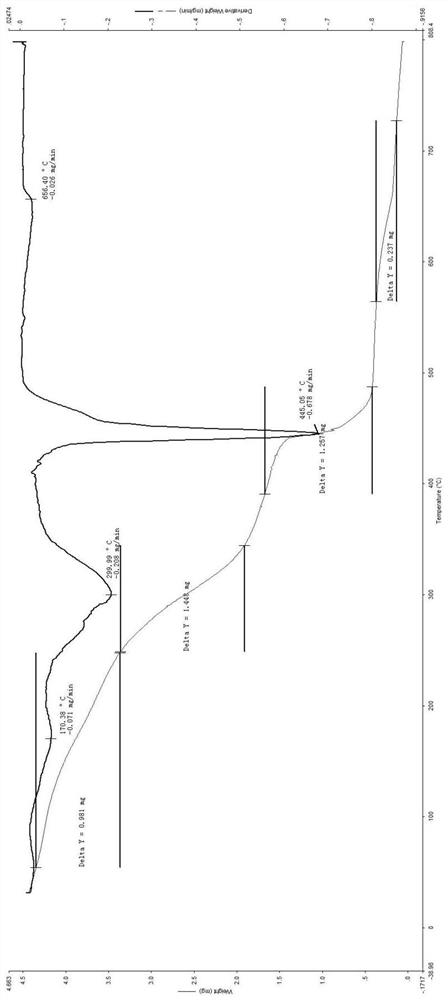

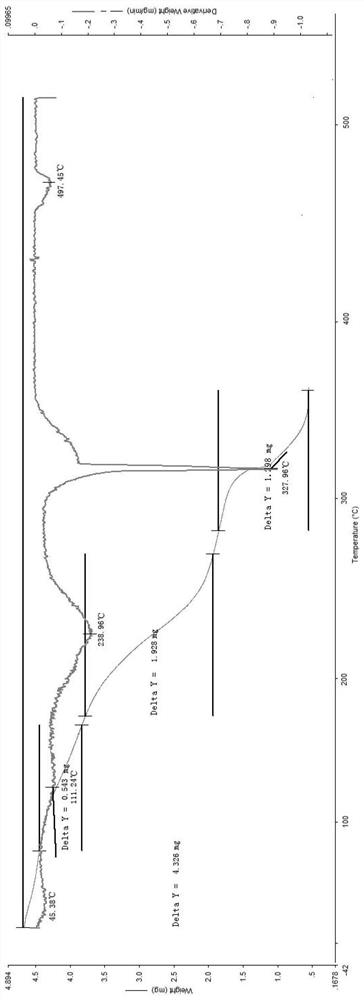

Image

Examples

Embodiment 1

[0027] A kind of preparation method of the low-temperature distillate that can promote strength, described preparation method comprises the following steps:

[0028] 1. Improve the formula design of Jintou Leaf Group

[0029] Table 1 Formula Design of Lifting Jintou Leaf Group

[0030] serial number tobacco raw material Formula ratio (wt%) 1 2017 Dali Burley Tobacco Medium One 65 2 2017 Hubei Jianshi Burley Tobacco Secondary Two 25 3 2017 Brazilian Burley BUB / S 10

[0031] 2. Ultrasonic extraction process: put the sample into a round bottom flask after being pulverized, add 8 times of 65wt% ethanol, and use ultrasonic extraction for 55 minutes under the condition of 55°C, with ultrasonic power of 500W, collect the filtrate for the first time, and use the same method for the residue Extract again, collect the second extract, combine the filtrates and concentrate the semifluid at 1.2500±0.008 to obtain the initial extract.

[0032] Filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com