Detection residual water removal device of dish washer

A dishwasher and residual water technology, which is applied in the field of dishwashers to remove and detect residual water, can solve the problem of inability to control the residual water in the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In view of the above problems, the embodiment of the present application provides a device for removing and detecting residual water in a dishwasher, which can realize the automation and standardization of the water blowing process.

[0041] The technical solutions of the embodiments of the present application are described in detail below with reference to the accompanying drawings.

[0042] A device for removing and detecting residual water in a dishwasher, comprising:

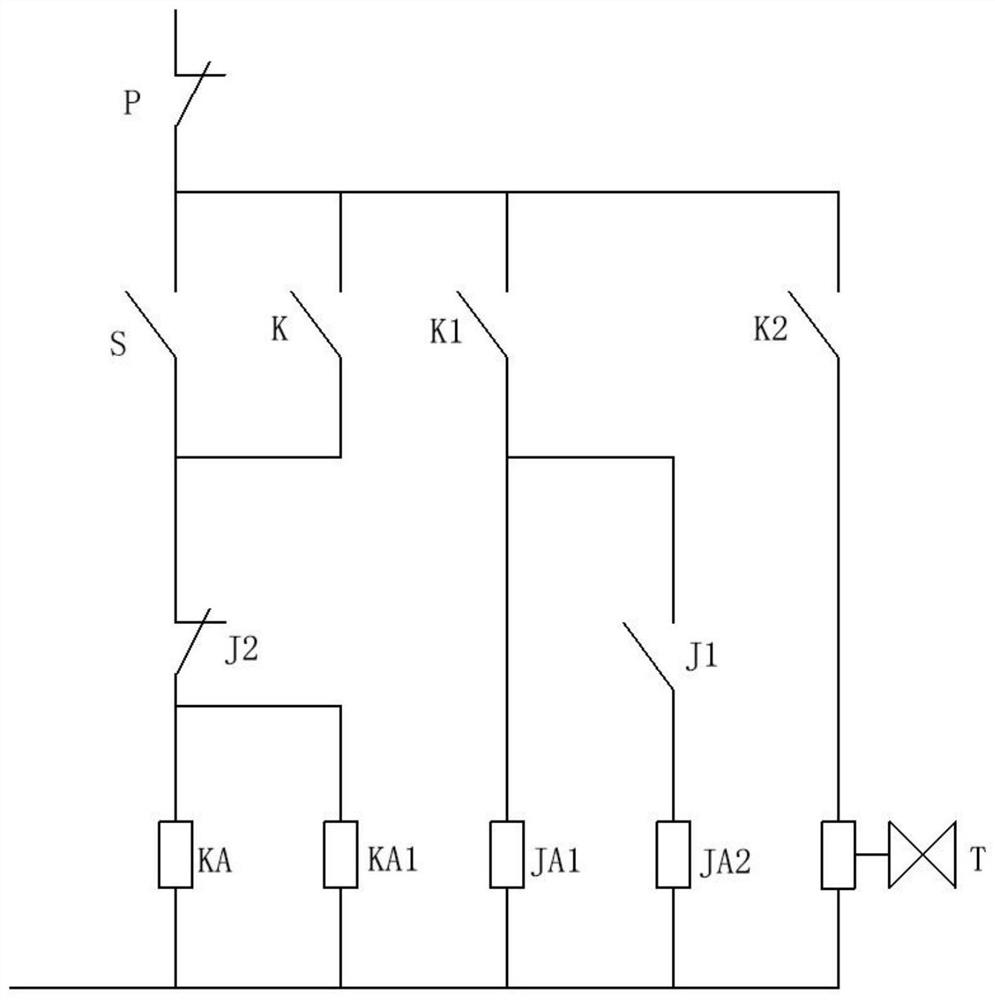

[0043] Air blower, water suction machine, solenoid valve and relay;

[0044] The blowing pipe mouth of the blower is connected with the water inlet of the dishwasher;

[0045] The water suction nozzle of the water suction machine is connected to the drain of the dishwasher;

[0046] The relay includes an intermediate relay and a time relay; the relay is electrically connected to the electromagnetic valve, and the intermediate relay sends a signal to the time relay and controls the opening of the tim...

Embodiment 2

[0063] In the water blowing process of the traditional dishwasher packaging section, in addition to the above-mentioned manual operations that cannot effectively control the residual water in the machine, resulting in potential quality hazards caused by non-standard air supply time, there is also the need for the operator to use both hands during the water blowing process. Support the water pipe to ensure the stable connection of the nozzle, and the manual operation wastes manpower. Therefore, the embodiment of the present application designs a technical solution for the above problems.

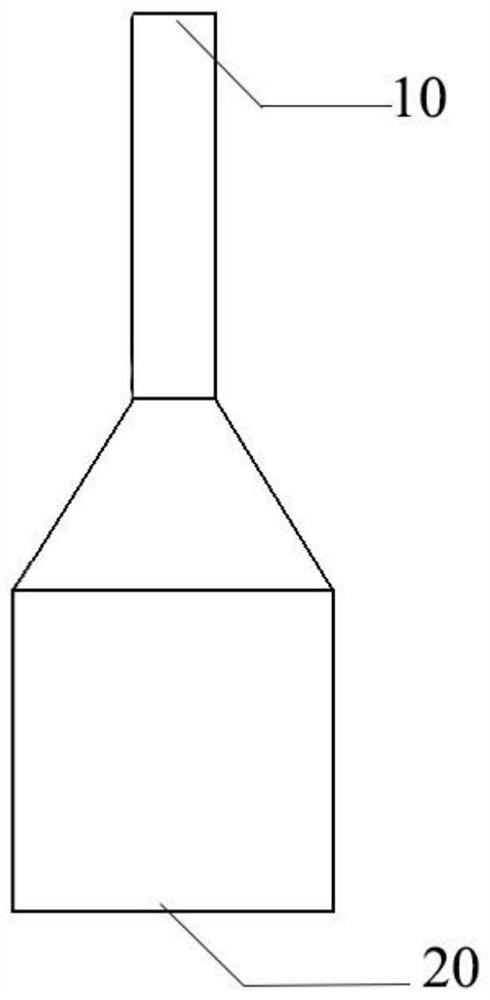

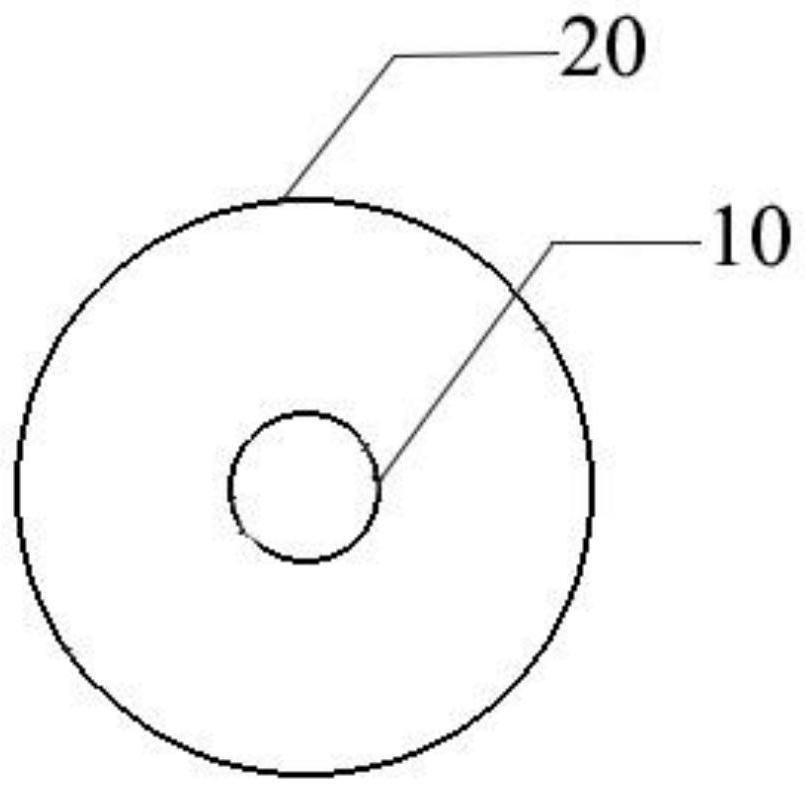

[0064] Based on the device for removing and detecting residual water in the dishwasher in the first embodiment above, the device for removing and detecting residual water in the dishwasher further includes: an air blowing connection tool;

[0065] The air blowing connection tool is fixed on the residual water removal and detection station. It is a tubular structure. The diameter of one end ma...

Embodiment 3

[0080] In order to improve the efficiency of removing and detecting residual water in the water blowing process, shorten the blowing time, and improve production efficiency, the embodiment of the present application is designed based on the device for removing and detecting residual water in the dishwasher shown in the first embodiment above.

[0081] The device for removing and detecting residual water in the dishwasher also includes: heating tooling;

[0082] The heating tool is arranged at the blowing nozzle of the blowing machine, and is used for heating and raising the temperature of the gas delivered by the blowing machine.

[0083] In the embodiment of the present application, the heating tool heats the gas blown by the blower, so that when the gas enters the dishwasher, it strengthens the evaporation of residual water detected in the dishwasher, so that the gas is blown by air pressure to promote the water vapor from The drain of the dishwasher is discharged to improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com