Automatic soft fruit packaging equipment

A kind of packaging equipment, soft technology, applied in the field of packaging design equipment, can solve the problems of restricting the effective use of customer resources, less than ideal packaging efficiency, large size and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

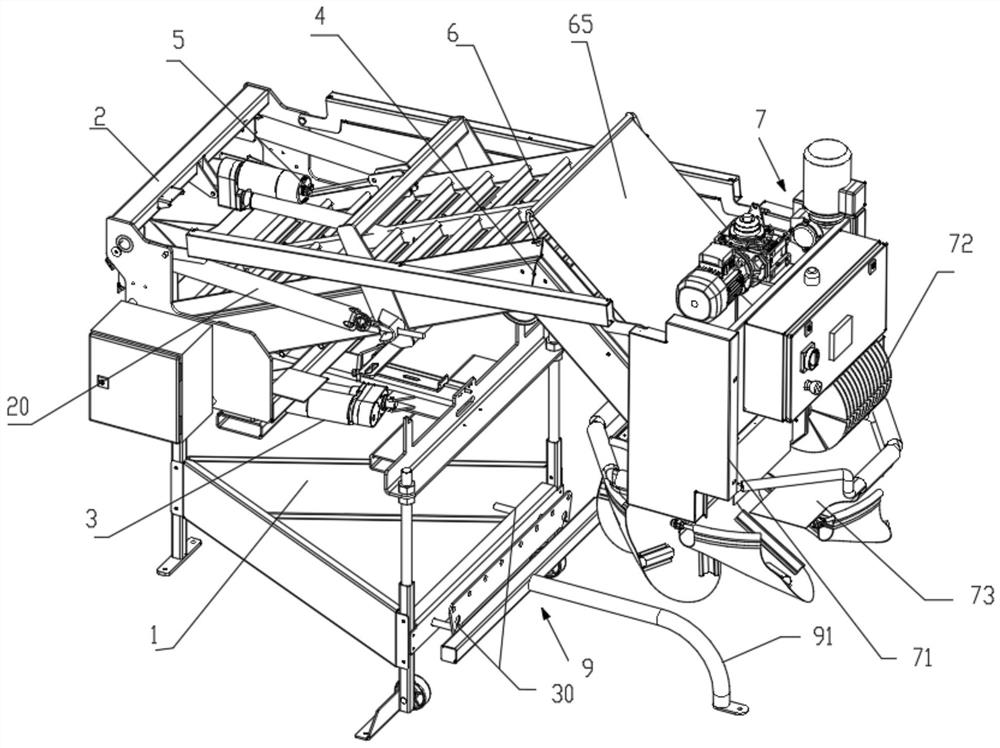

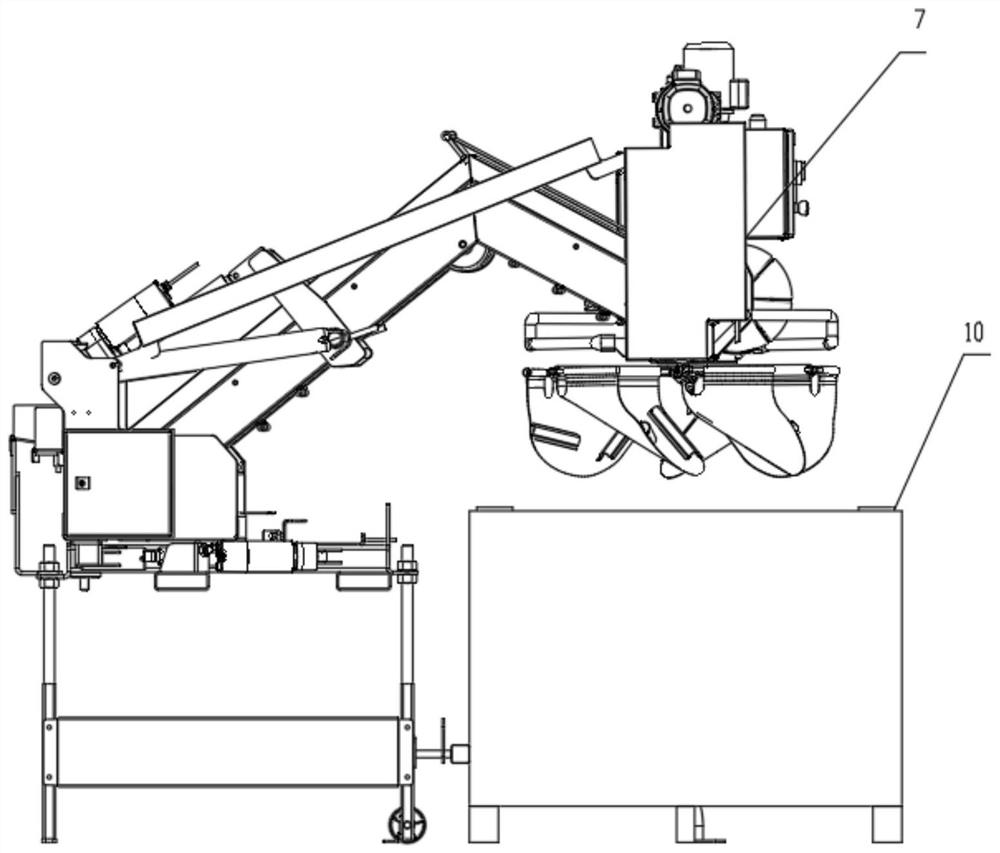

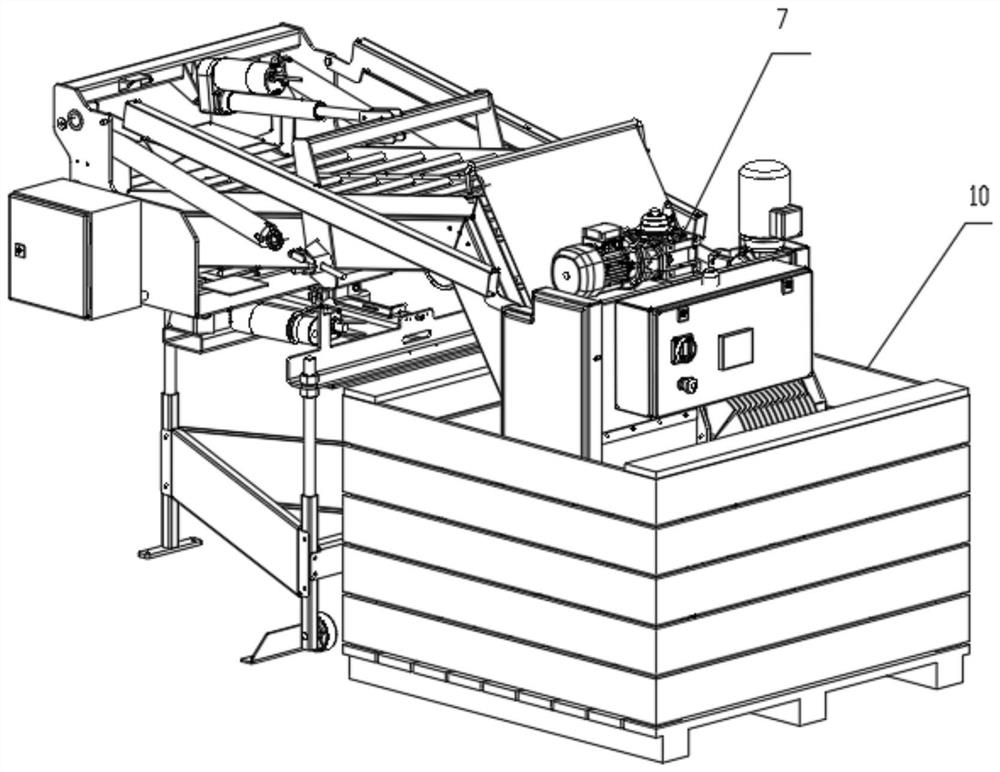

[0054] Example: such as Figure 1 to Figure 19 As shown, an automatic soft fruit packaging equipment, figure 1 , 2 As shown in and 3, the fruit packaging equipment includes a support mechanism 1, the support mechanism is equipped with a horizontal support 2 and a horizontal drive unit 3 capable of driving the horizontal support to move in a horizontal plane, and the horizontal support is equipped with a delivery support 4 And the up and down driving unit 5 that can drive the conveying support to lift up and down in the vertical plane, the conveying support is equipped with a conveying mechanism 6 for conveying fruit and a full box automatic induction filling device 7, defining the location of the full box automatic induction filling device One side is the front, and the side opposite to it is the rear. The full tank automatic induction filling device is located downstream of the conveying mechanism. The full tank automatic induction filling device includes a support frame 71,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com