Automatic material roll stacking device

An automatic stacking and material roll technology, which is applied in the direction of transportation, packaging, and object stacking, can solve problems such as low work efficiency, unstable stacking quality, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

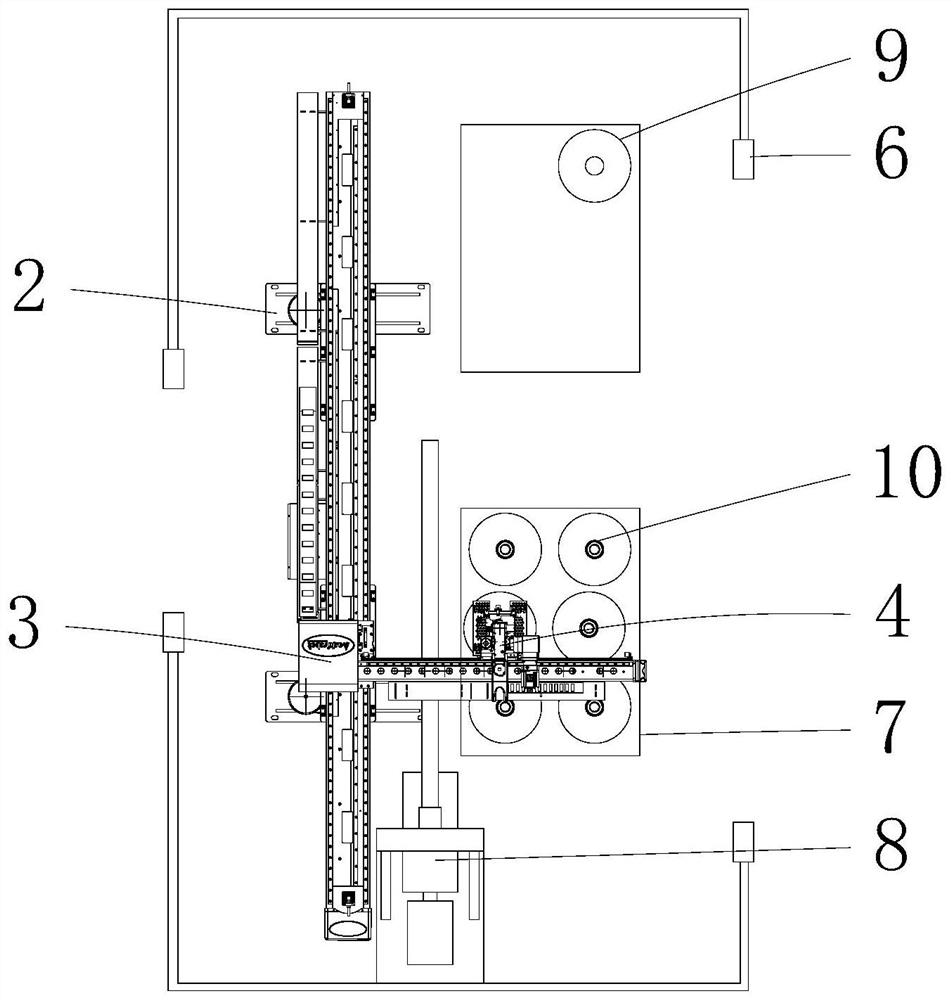

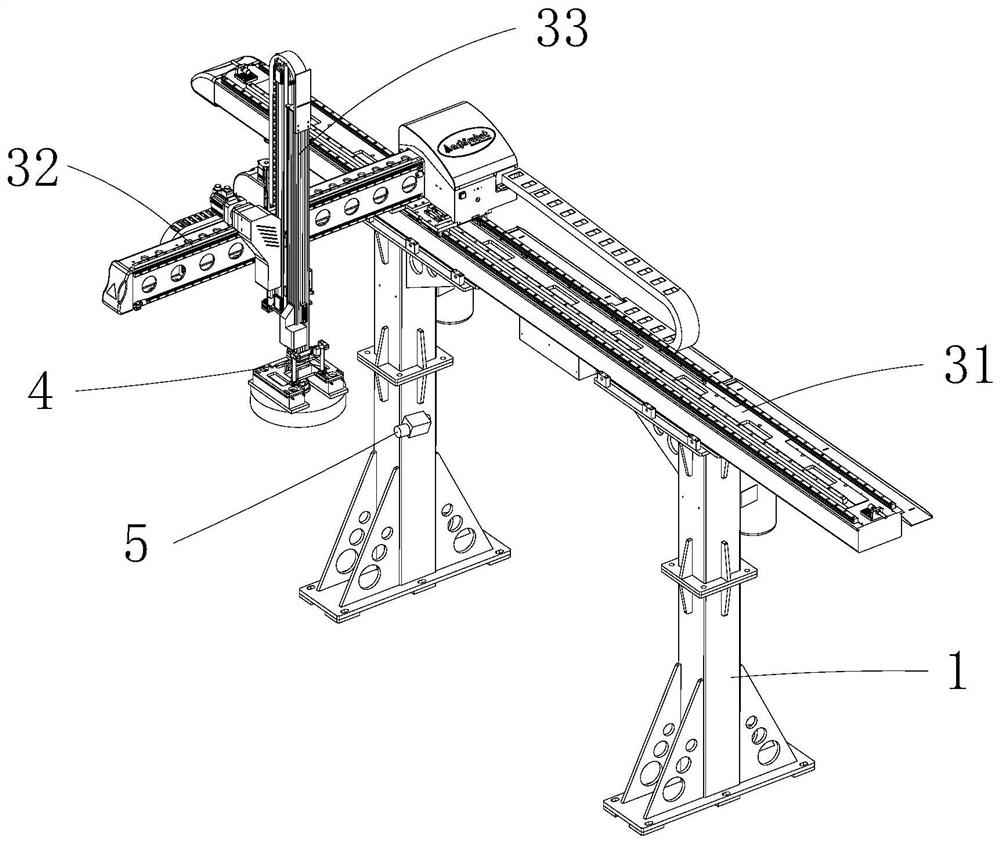

[0030] Such as Figure 1-4 As shown, the present invention provides an automatic stacking device for material rolls, which includes a fence 1 and a vertical frame 2 arranged in the fence 1. It is characterized in that the vertical frame 2 is provided with a The traveling mechanism 3; preferably, the traveling mechanism 3 includes an X-axis linear module 31 erected on the top of the vertical frame 2, a Y-axis linear module 32 installed on the X-axis linear module 31, and a Y-axis linear module installed on the Y-axis linear module. The Z-axis lifting assembly 33 on the group 32 realizes precise stroke control. The walking mechanism 3 is provided with a material suction mechanism 4, and the vertical frame 2 is also provided with a code scanning mechanism 5 that cooperates with the material suction mechanism 4; The coding of the product 9 can be calculated to obtain the specific position of the product 9.

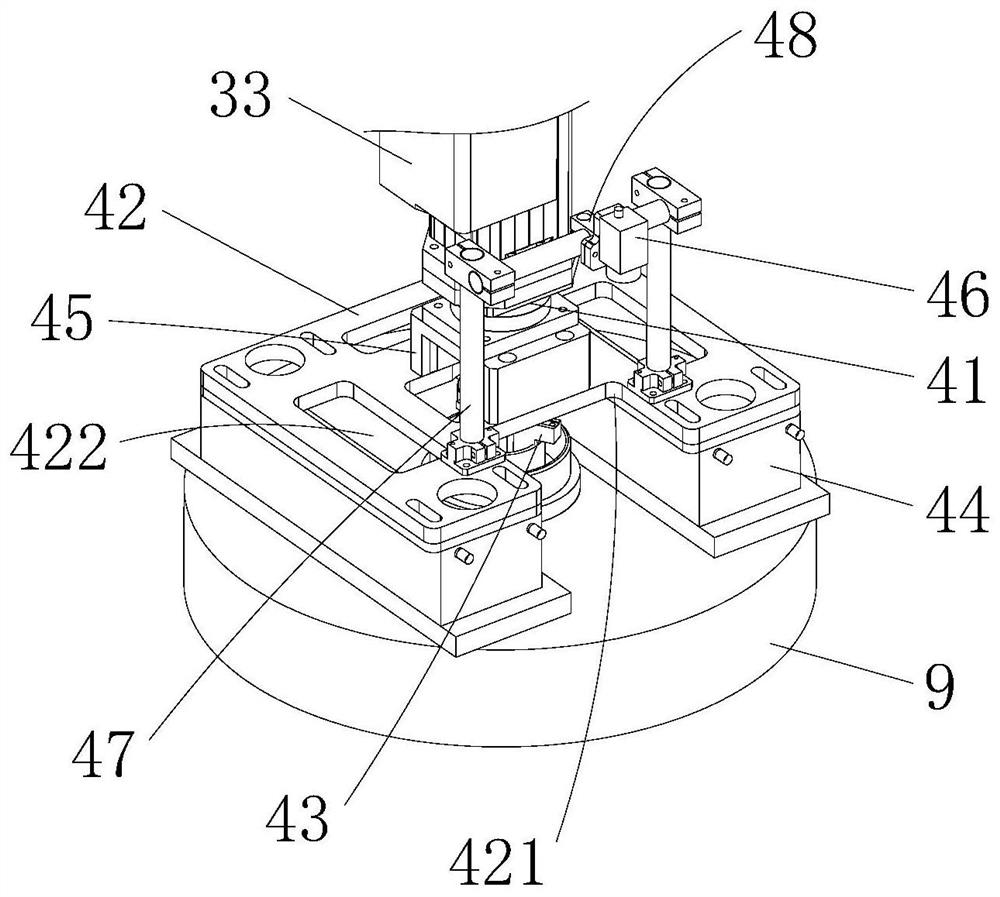

[0031] The suction mechanism 4 includes a steering motor 41 vertically ...

Embodiment 2

[0038] Such as figure 1 , Figure 5As shown, the present invention also provides an automatic stacking device for material rolls, which is different from Embodiment 1 in that: a material rack 7 is provided in front of the vertical frame 2, and an air supply mechanism 8 is provided between the material rack 7 and the scanning mechanism 5; Preferably, the air supply mechanism 8 includes a fixed frame 81 arranged on one side of the vertical frame 2, an air supply device 82 arranged at the bottom of the fixed frame 81, a rotating assembly 83 and an air pipe 84 arranged at the top of the fixed frame 81, and the air pipe 84 Horizontally arranged between the material rack 7 and the code scanning mechanism 5, the air duct 84 is provided with an air inlet 841 connected to the air supply device 82, the air duct 84 is provided with a plurality of air outlets 842 along the length direction, and one end of the air duct 84 Sealed, the other end is connected with the rotating assembly 83. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com