High-temperature-resistant long-service-life composite coating on surface of carbon/carbon composite material and preparation method

A carbon composite material and composite coating technology, which is applied in the high temperature resistant and long life composite coating and preparation on the surface of carbon/carbon composite material, B2-SiC-Si/SiC-Si composite anti-oxidation coating and its preparation field. Solve the problems of glass layer cracking and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take a certain amount of phenolic resin in a beaker, add a certain amount of absolute ethanol therein, wherein the mass ratio of phenolic resin to absolute ethanol is 2:8, stir it after ultrasonic treatment to obtain the phenolic resin solution A;

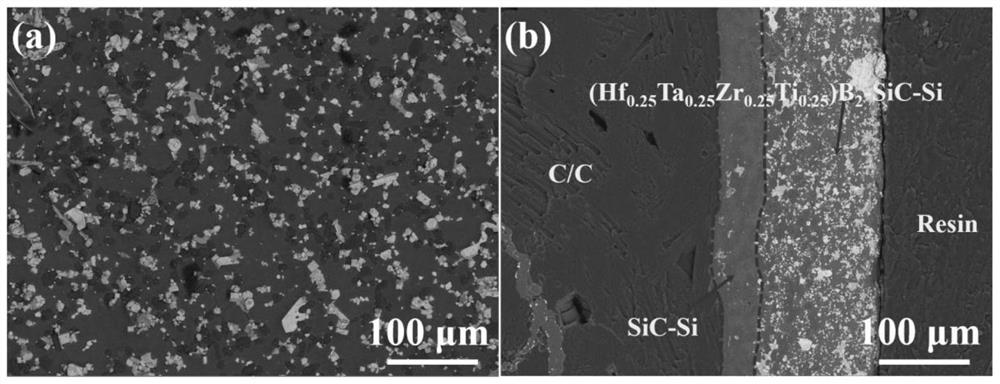

[0027] (2) add SiC powder in phenolic resin solution A, get slurry B after stirring evenly, wherein the massfraction of SiC is 40wt%; In phenolic resin solution A, add (Hf 0.25 Ta 0.25 Zr 0.25 Ti 0.25 )B 2 and SiC powder, wherein the mass fraction of SiC is 10wt%, (Hf 0.25 Ta 0.25 Zr 0.25 Ti 0.25 )B 2 The mass fraction of is 30wt%, and after stirring uniformly, slurry C is obtained;

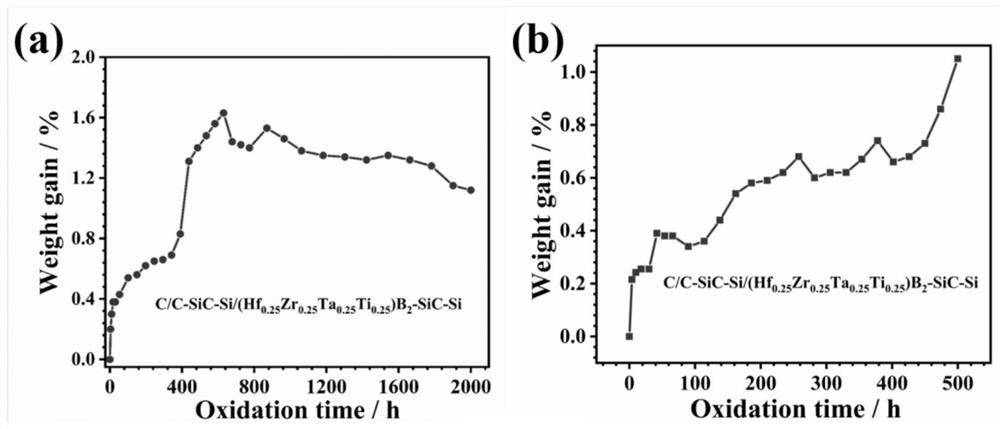

[0028] (3) Dip the C / C composite material into the slurry B for 3 seconds, take it out and dry it in an oven at 50°C for 30 minutes. After repeating this process 3 times, a SiC inner coating is obtained; The C / C composite material was dipped into the slurry C for 3s, and then dried in an oven at 50°C for 30min after taking it out....

Embodiment 2

[0032] (1) Take a certain amount of phenolic resin in a beaker, add a certain amount of dehydrated alcohol therein, wherein the mass ratio of phenolic resin and dehydrated alcohol is 1:9, stir it after ultrasonic treatment to obtain a phenolic resin solution A;

[0033] (2) add SiC powder in phenolic resin solution A, get slurry B after stirring evenly, wherein the massfraction of SiC is 35wt%; In phenolic resin solution A, add (Hf 0.25 Ta 0.25 Zr 0.25 Ti 0.25 )B 2 and SiC powder, wherein the mass fraction of SiC is 15wt%, (Hf 0.25 Ta 0.25 Zr 0.25 Ti 0.25 )B 2 The mass fraction of is 35wt%, after stirring uniformly, slurry C is obtained;

[0034] (3) Dip the C / C composite material into the slurry B for 4 seconds, take it out and dry it in an oven at 70°C for 15 minutes. After repeating this process 3 times, a SiC inner coating is obtained; The C / C composite material was dipped into the slurry C for 4s, and then dried in an oven at 70°C for 15min after taking it out. ...

Embodiment 3

[0038] (1) Take a certain amount of phenolic resin in a beaker, add a certain amount of absolute ethanol therein, wherein the mass ratio of phenolic resin to absolute ethanol is 2:8, stir it after ultrasonic treatment to obtain the phenolic resin solution A;

[0039] (2) add SiC powder in phenolic resin solution A, get slurry B after stirring evenly, wherein the massfraction of SiC is 30wt%; In phenolic resin solution A, add (Hf 0.25 Ta 0.25 Zr 0.25 Ti 0.25 )B 2 and SiC powder, wherein the mass fraction of SiC is 20wt%, (Hf 0.25 Ta 0.25 Zr 0.25 Ti 0.25 )B 2 The mass fraction of is 40wt%, after stirring uniformly, slurry C is obtained;

[0040] (3) Dip the C / C composite material into the slurry B for 5 seconds, take it out and dry it in an oven at 80°C for 10 minutes. After repeating this process 3 times, a SiC inner coating is obtained; The C / C composite material was dipped into the slurry C for 5s, and then dried in an oven at 80°C for 10min after taking it out. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com