Electrolyte low-position circulating tank capable of removing bubbles

A technology for removing bubbles and electrolyte, applied in the direction of electrolysis process, electrolysis components, and process efficiency improvement, etc., can solve the problems of poor quality of electrolytic copper and inability to remove fine dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

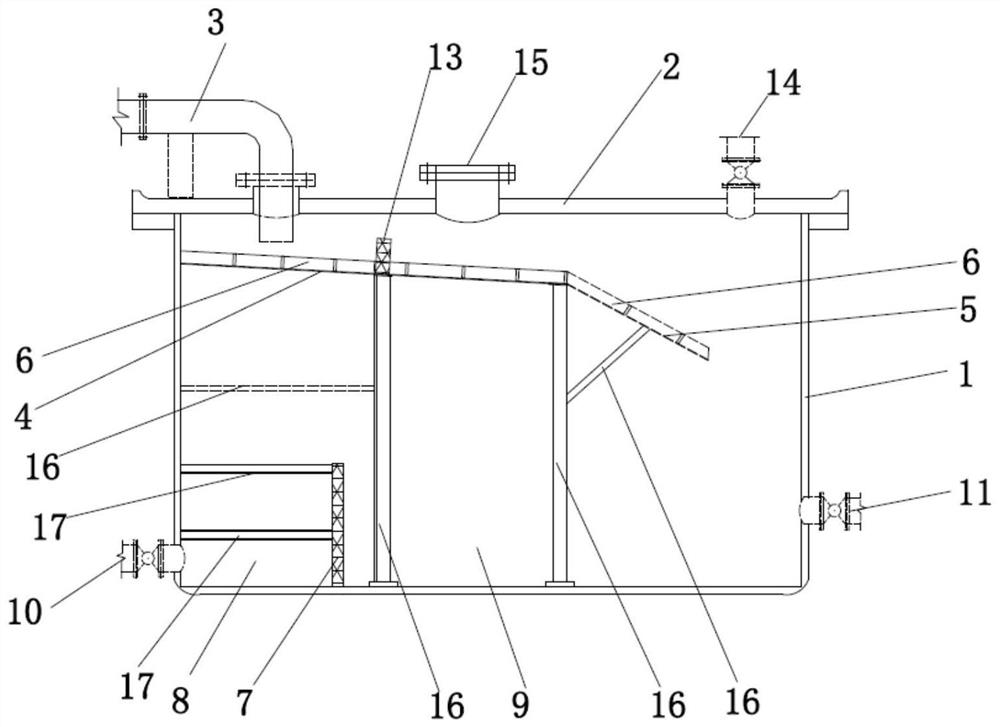

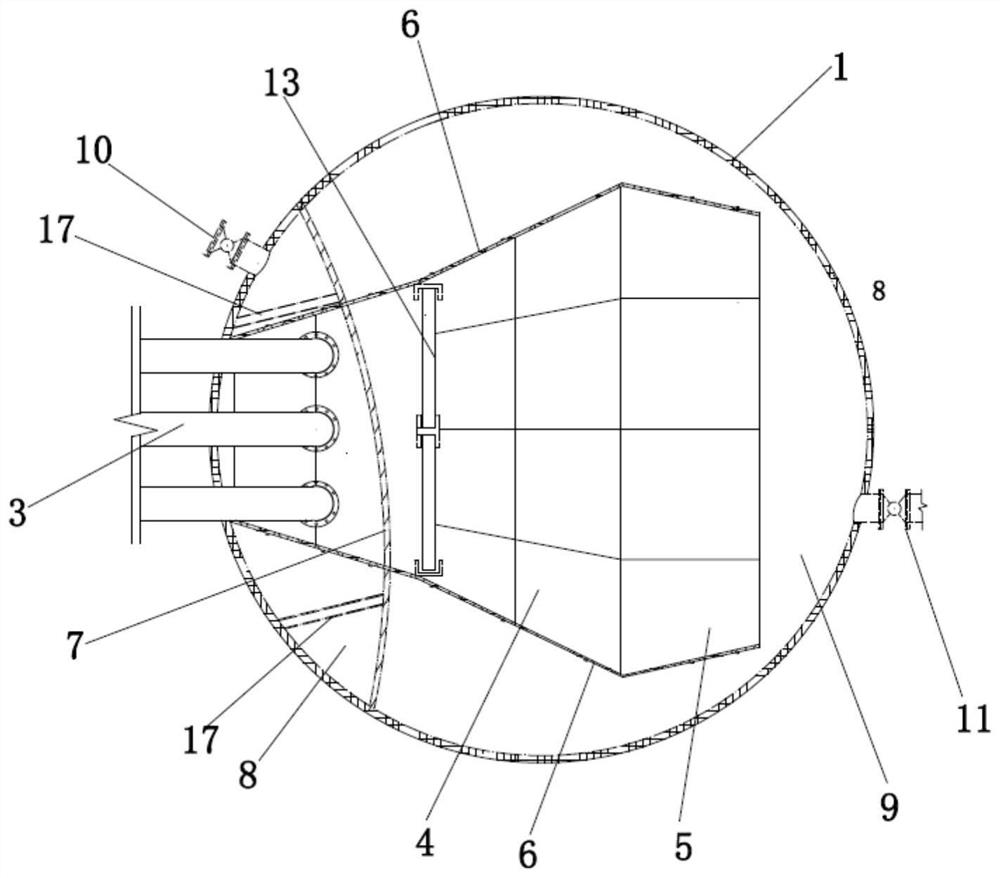

[0065] Baotou Huading Copper Industry Development Co., Ltd. has a copper electrolytic refining device with an annual output of 30,000 tons. The circulation of its electrolyte is as attached Figure 10 shown.

[0066] Its circulating low-level tank is replaced with the electrolyte low-level circulating tank in the present invention, and the equipment parameters are as follows:

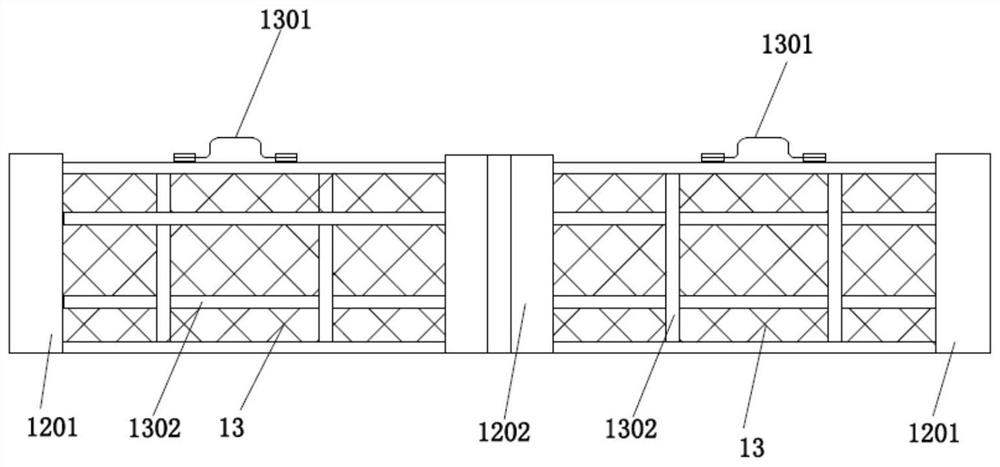

[0067] 1. The total area of the first electrolyte degassing plate and the second electrolyte degassing plate is 12m 2 , the inclination angle of the first electrolyte degassing plate is 15°, and the inclination angle of the second electrolyte degassing plate is 65°.

[0068] 2. The height of the sidewall of the degassing plate is 100mm;

[0069] 3. The height of the electrolyte settlement baffle is 1.2m;

[0070] 4. The internal volume of the storage pool is 6m 3 ;

[0071] 5. The inner volume of the separation and sedimentation tank is 12m 3 ;

[0072] 6. The filter net is 50mm thick and 400m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com