Impeller pipeline driving structure of circulating water power generation equipment and process method of impeller pipeline driving structure

A technology of power generation equipment and drive structure, which is applied in the fields of hydroelectric power generation, mechanical equipment, engine functions, etc., and can solve problems such as large engineering volume and damage to the environment and ecology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

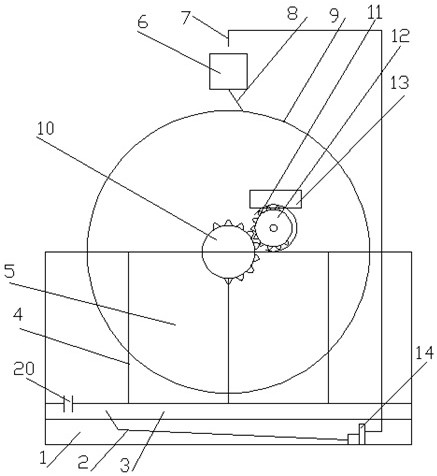

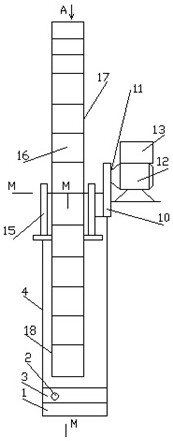

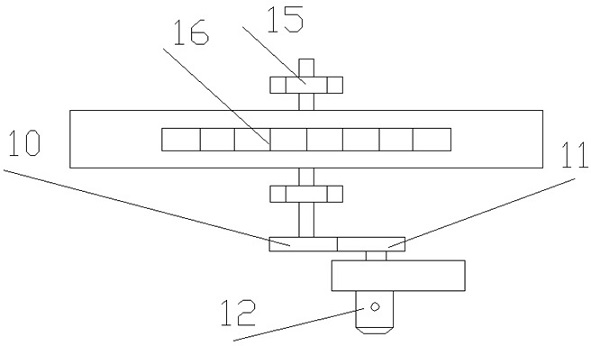

Embodiment 1

[0026] Embodiment 1, with reference to the accompanying drawings, the patent application of the present invention is a divisional application for components in the circulating hydrodynamic power generation equipment and its process method filed by the applicant on the same day, which belongs to the classified design of the original main engine. Specifically: a seat frame 4 is installed above the pool 3, an impeller 9 is installed on the seat frame 4 and a generator set 12 is installed, an electric meter box 13 is housed on the top of the generator set 12, a drive shaft 22 is arranged on the connection plate 21, and the drive shaft 22 is equipped with a drive gear 10, Generator set 12 has driven shaft 23, and driven shaft 23 is equipped with passive gear 11, and driving gear 10 meshes transmission passive gear 11, thereby drives generator set 12 work, and impeller 9 bottom faces have 1~50cm apart from pool 3 water surfaces. The periphery of the seat frame 4 is a pool 3 composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com