Self-powered high-sensitivity bridge stress detection system and detection method

A stress detection, high-sensitivity technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, force measurement, photovoltaic power plants, etc. personal level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

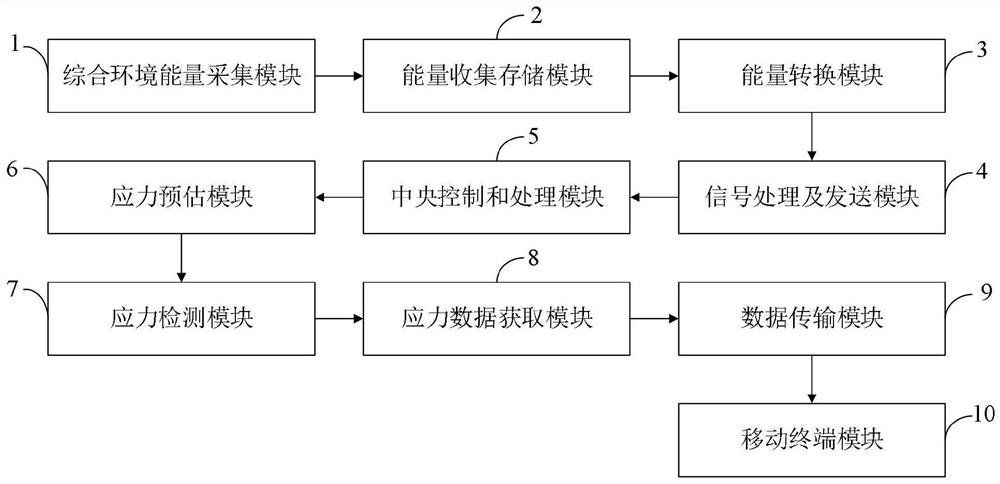

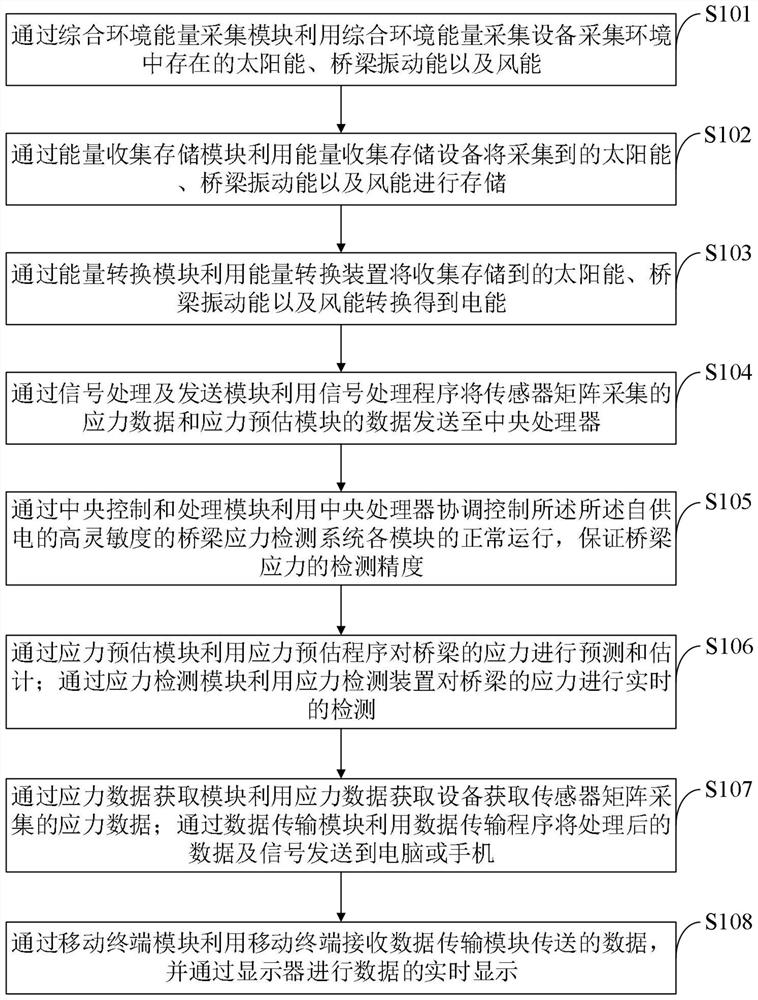

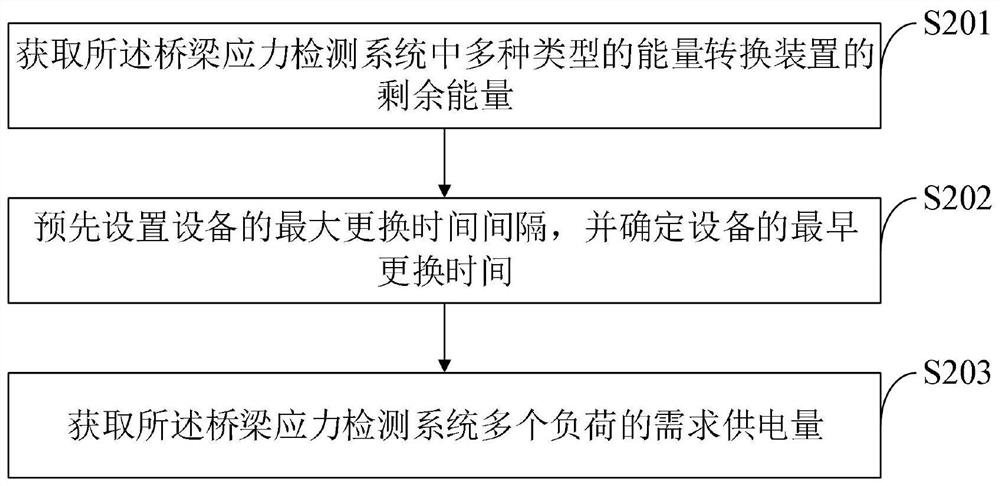

[0100] The self-powered high-sensitivity bridge stress detection method provided by the embodiment of the present invention is as follows: figure 2 As shown, as a preferred embodiment, such as image 3 As shown, the method for converting collected and stored solar energy, bridge vibration energy, and wind energy into electrical energy through the energy conversion module and the energy conversion device provided by the embodiment of the present invention includes:

[0101] S201. Obtain residual energy of various types of energy conversion devices in the bridge stress detection system;

[0102] S202, pre-setting the maximum replacement time interval of the equipment, and determining the earliest replacement time of the equipment;

[0103] S203. Obtain the required power supply of multiple loads of the bridge stress detection system.

[0104] Obtaining the residual energy E(t) of multiple types of energy conversion devices in the bridge stress detection system provided by the...

Embodiment 2

[0116] The self-powered high-sensitivity bridge stress detection method provided by the embodiment of the present invention is as follows: figure 2 As shown, as a preferred embodiment, such as Figure 4 As shown, the method provided by the embodiment of the present invention utilizes the central processing unit to coordinate and control the normal operation of each module of the self-powered high-sensitivity bridge stress detection system through the central control and processing module, and the method for ensuring the detection accuracy of the bridge stress includes :

[0117] S301, calculating an error value according to the input stress data, and calculating an error change rate according to the error value;

[0118] S302, receiving the error value and the error change rate, and using the fuzzy rules to perform adaptive tuning on the PID parameters of the PID controller, and output the change amount of the PID parameters;

[0119] S303, receiving the error value and err...

Embodiment 3

[0130] The self-powered high-sensitivity bridge stress detection method provided by the embodiment of the present invention is as follows: figure 2 As shown, as a preferred embodiment, such as Figure 5 As shown, the method for real-time detection of the stress of the bridge by using the stress detection device through the stress detection module provided by the embodiment of the present invention includes:

[0131] S401, amplifying the initial electrical signal to obtain the excitation electrical signal; sending the excitation electrical signal to the ultrasonic transmitting probe;

[0132] S402. Control the ultrasonic transmitting probe to transmit ultrasonic signals to the bridge, and determine the transmitting time of the ultrasonic signals;

[0133] S403. Control the at least one ultrasonic receiving probe to receive the ultrasonic critical longitudinal wave signal, and determine the receiving time for each ultrasonic receiving probe in the at least one ultrasonic recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com