Water-cooling radiator with good heat absorption performance

A water-cooled radiator and heat-absorbing technology, which is applied to electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., and can solve the problems of enlargement, insufficient use of cooling water, and unreliable heat dissipation capacity of radiators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

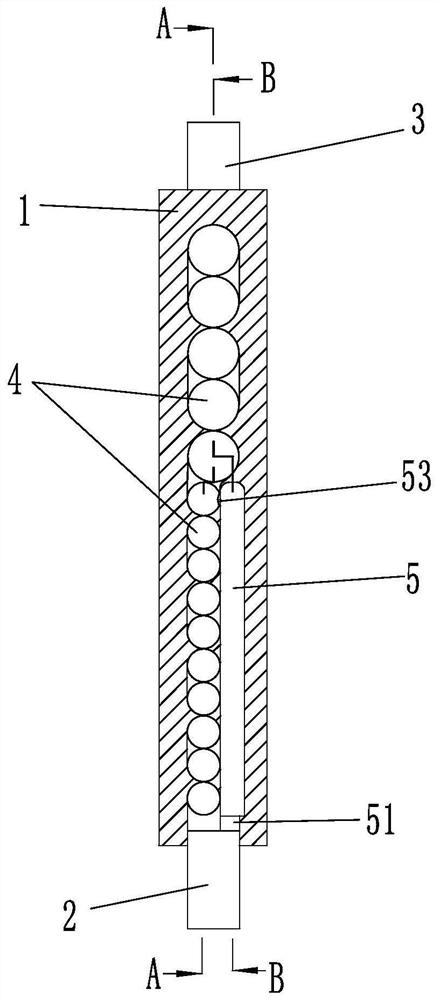

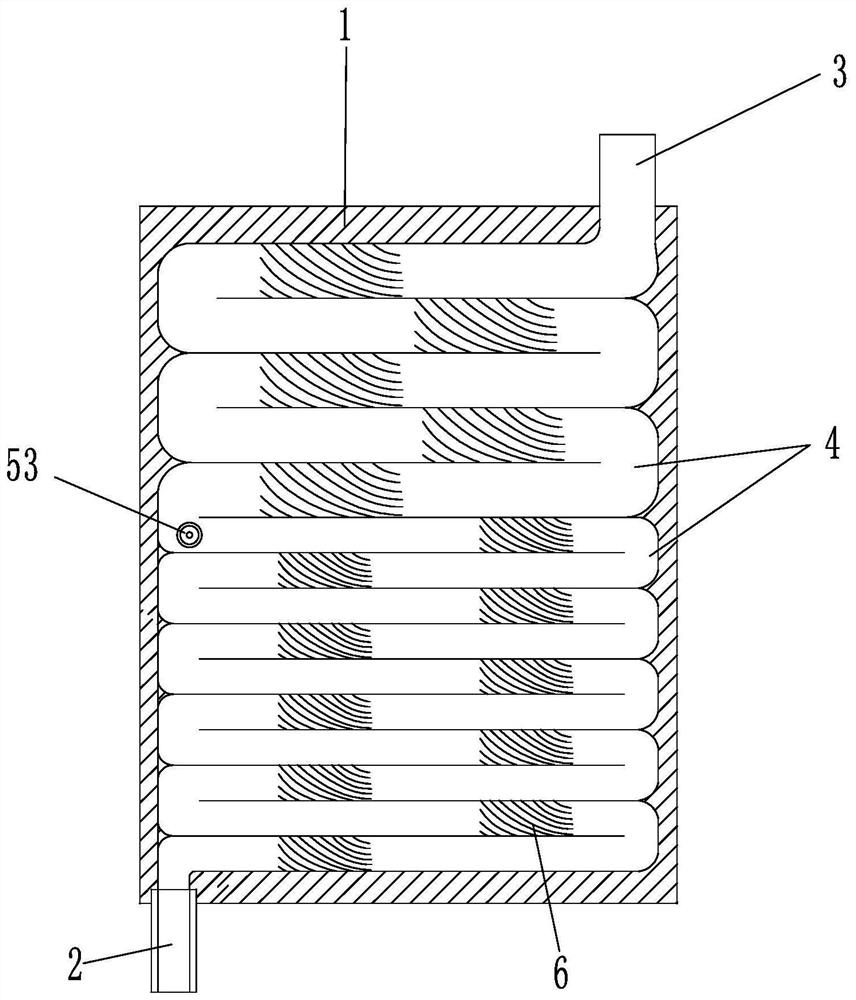

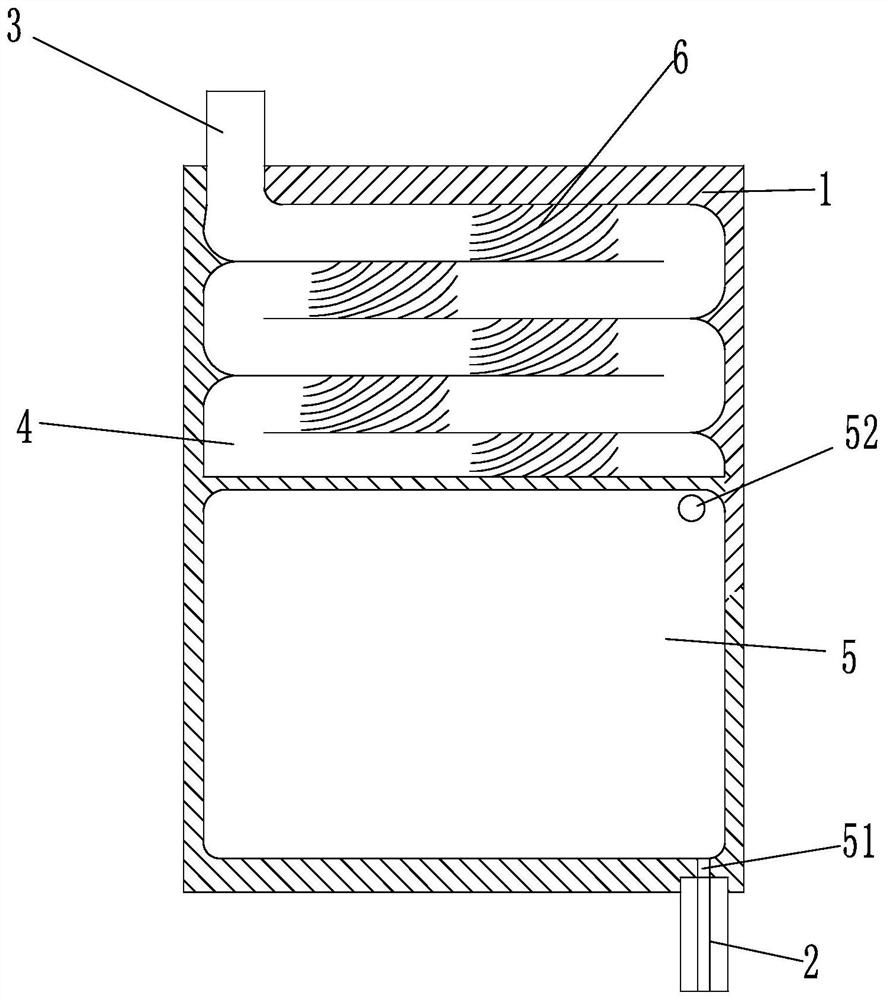

[0027] Figure 1 to Figure 5 Among them, a water-cooled radiator with good heat absorption performance includes a radiator body 1, a water inlet pipe 2 and a water outlet pipe 3, and is characterized in that the radiator body 1 is provided with a cooling water channel 4 connecting the water inlet pipe 2 and the water outlet pipe 3 , the cooling water flows through the water inlet pipe 2, the cooling water channel 4 and the water outlet pipe 3 in sequence; The interior of the device body 1 is arranged in a reciprocating "S" shape. The radiator body 1 is provided with a bypass layer 5 on a plane parallel to the cooling water channel 4. The bypass layer 5 is a copper product embedded in the radiator body 1. The bypass layer 5 and the cooling channel 4 are bonded and fixed by heat-conducting adhesive. . The bypass layer 5 is provided with a cavity for circulating cooling water, and the bypass layer 5 is provided with a water inlet 51 and a water outlet 52 , and the water inlet 5...

Embodiment 2

[0029] Such as Figure 6 As shown, a water-cooled radiator with good heat absorption performance differs from Embodiment 1 in that the water inlet pipe 2 and the water outlet pipe 3 are located on the same side of the radiator body 1 .

[0030] The one-way flow of the cooling water body in the bypass layer 5 is guaranteed by the one-way valve 53, preventing the water body in the cooling pipeline from flowing back to the bypass layer 5; compared with the cooling water in the cooling water channel 4, the cooling water in the bypass layer 5 The heat transfer speed is far beyond, so that the temperature difference between the cooling water in the bypass layer 5 is small, so that the cooling water in the bypass layer 5 can balance the heat absorption efficiency of each part of the cooling water channel 4 below it; After the cooling water in the passing layer 5 absorbs part of the heat, the temperature difference of the cooling water channel 4 can be kept larger than that of the mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com