Optical design system based on tablet visual inspection, shooting method and controller

A technology of optical design and visual inspection, applied in lighting and shooting methods, optical design systems based on visual inspection of tablets, and controllers, which can solve the problem of low detection rate, reduced algorithm detection accuracy, and inability to complete automatic image acquisition, etc. problem, to achieve the effect of improving the detection rate and enriching the coverage angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

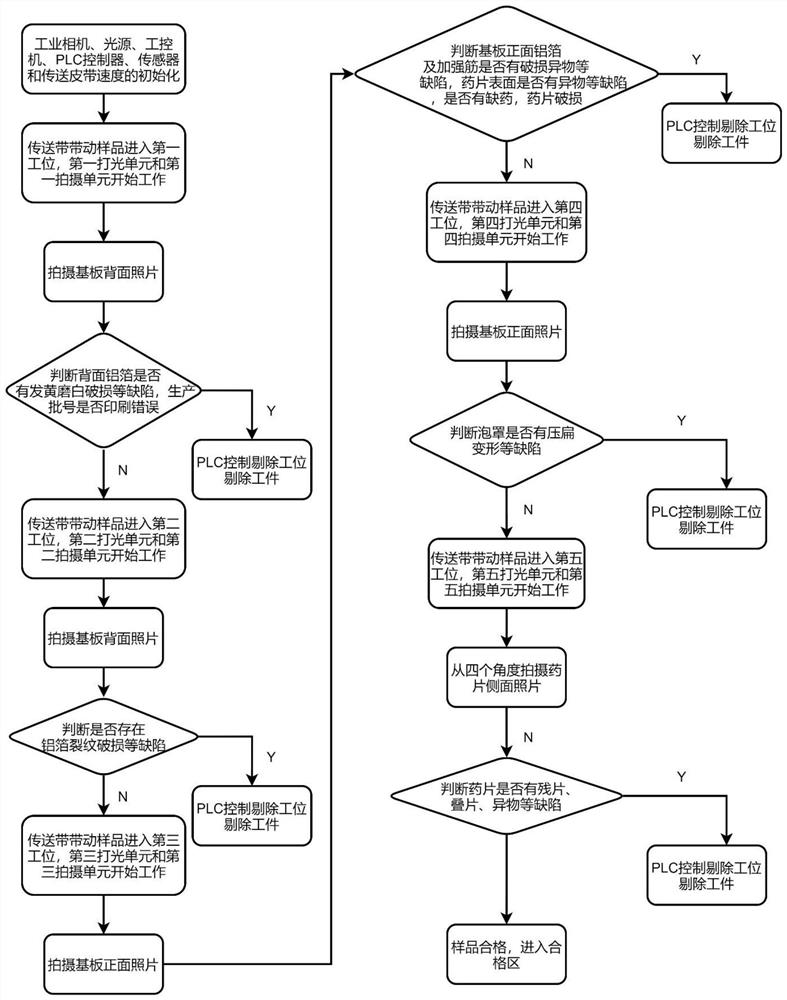

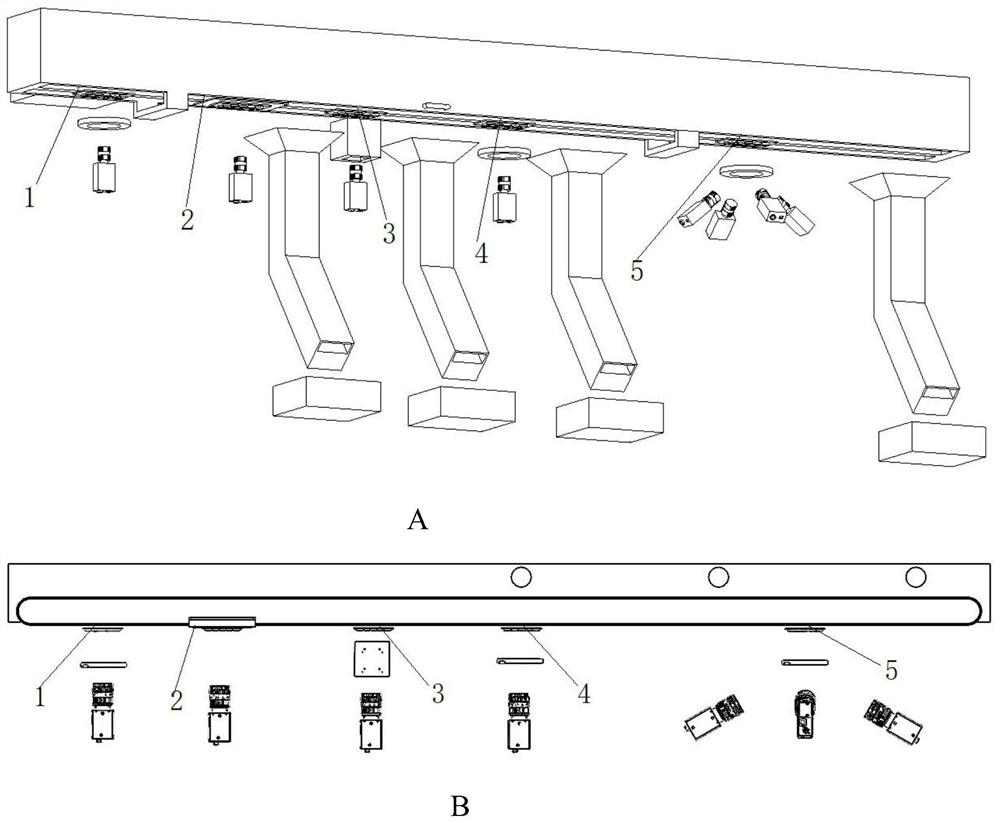

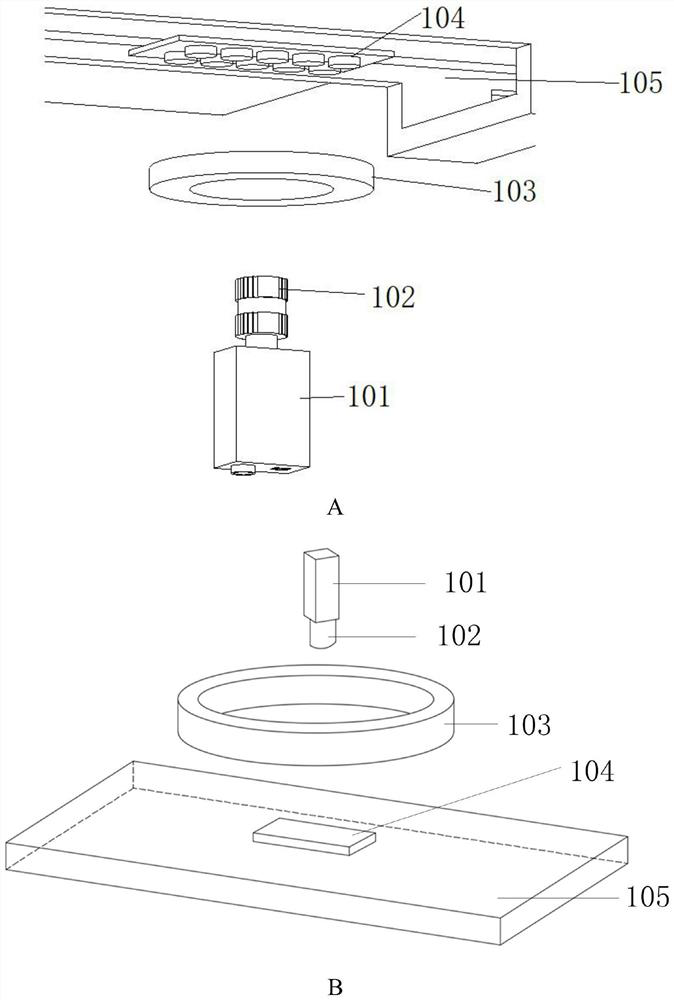

[0153] The technical solutions provided by the disclosed embodiments of the present invention relate to an optical design system based on visual detection of tablets, and in particular, to the technical field of tablet quality detection and visual optical design. In the related art, manual or semi-automatic detection is not conducive to improving detection efficiency and ensuring detection accuracy, and the existing optical solutions based on visual detection also have some limitations. For example, in the existing tablet detection patent, the following Shooting plan: Use an area scan camera to shoot the upper surface of the tablet on the tablet tray and in a static state, identify the defects, and remove the defective products.

[0154] The existing solution chooses to use an area scan camera to shoot the upper surface from above, so that the side surface of the tablet and the back of the tablet substrate will form a blind area, resulting in an incomplete tablet area, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com